Introduce:

In this fast-paced technological era, the need for rapid prototyping has gained tremendous momentum, especially in the field of printed circuit board (PCB) development. But how do engineers ensure that speed does not affect the signal integrity of the PCB? In this blog post, we’ll explore strategies and best practices to help you master the art of rapid PCB prototyping while carefully considering signal integrity considerations.

Understand the importance of signal integrity in PCB design:

Signal integrity refers to the ability of a signal to propagate through a PCB without being distorted, degraded, or lost during transmission. Poor signal integrity can lead to a variety of problems such as data errors, performance degradation, and increased susceptibility to interference. When prototyping PCBs, it is critical to prioritize signal integrity to ensure the functionality and reliability of the final product.

1. Follow signal integrity design guidelines:

To ensure optimal signal integrity, specific design guidelines must be followed during the prototyping phase. These guidelines include:

A. Proper component placement: Strategically placing components on the PCB helps minimize the length of signal traces, thereby reducing the risk of signal degradation. Grouping related components together and following manufacturer placement recommendations are critical steps in optimizing signal integrity.

b. Trace length matching: For high-speed signals, maintaining consistent trace lengths is critical to preventing timing deviations and signal distortion. Ensure traces carrying the same signals are the same length to minimize potential timing mismatches.

C. Impedance Control: Designing PCB traces to match the characteristic impedance of the transmission line improves signal integrity by minimizing reflections. Impedance control techniques, such as controlled impedance routing, are critical in high frequency applications.

2. Utilize advanced PCB design tools:

Leveraging cutting-edge PCB design software equipped with signal integrity analysis capabilities can greatly simplify the prototyping process. These tools enable engineers to simulate and analyze the behavior of PCB designs before manufacturing to identify potential signal integrity issues early.

A. Simulation and Modeling: Performing simulations provides a comprehensive assessment of signal behavior, providing insight into potential signal integrity issues. By simulating various scenarios, designers can identify and correct issues related to reflections, crosstalk, and electromagnetic interference (EMI).

b. Design Rule Checking (DRC): Implementing DRC in PCB design software ensures that the design complies with specific signal integrity guidelines. It helps detect and resolve potential design flaws in a timely manner.

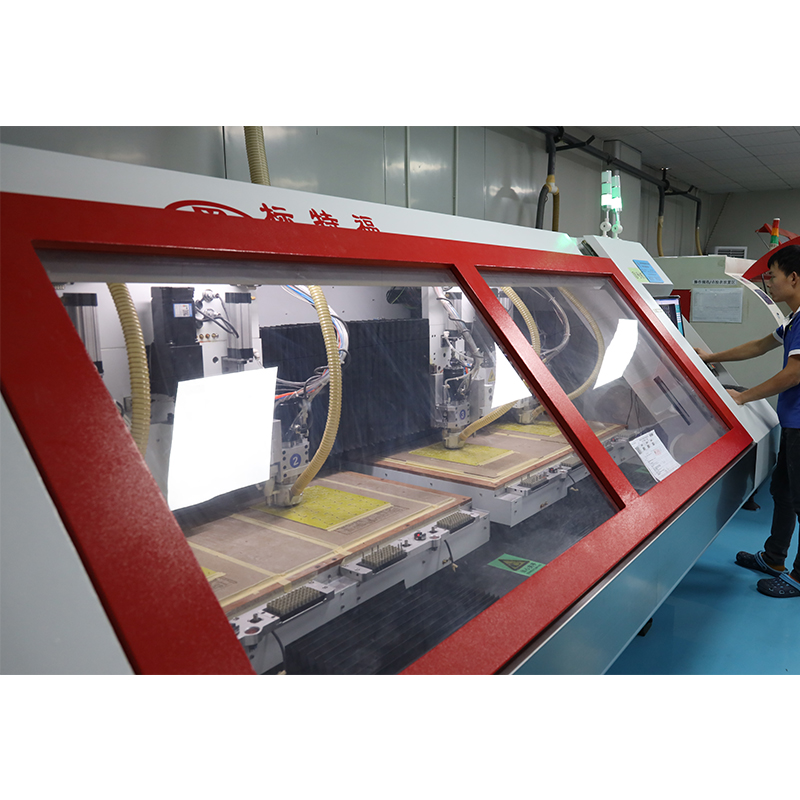

3. Cooperate with PCB manufacturers:

Working closely with an experienced PCB manufacturer from the beginning can significantly simplify the prototyping process. Manufacturers can provide valuable insights into signal integrity issues and recommend modifications to optimize the design.

A. Material Selection: Working with the manufacturer will enable you to choose the right materials for your PCB design. Materials with low dielectric loss tangent and controlled dielectric constant can improve signal integrity.

b. Design for Manufacturability (DFM): Involving manufacturers during the design phase ensures that the design is optimized for manufacturing and reduces potential signal integrity issues caused by poor manufacturability.

4. Iterative testing and optimization:

Once the prototype is complete, thorough testing must be performed to verify signal integrity. An iterative process of testing, identifying issues, and implementing optimizations is critical to achieving excellent signal integrity.

In conclusion:

Rapid PCB prototyping with signal integrity in mind can be challenging, but by employing the right design techniques, leveraging advanced PCB design tools, collaborating with manufacturers, and conducting iterative testing, engineers can optimize signal integrity while achieving rapid time to market. Prioritizing signal integrity throughout the prototyping process ensures the final product operates reliably and meets the demands of the modern electronics industry.

Post time: Oct-21-2023

Back