Introduction

As a seasoned rigid-flex PCB engineer with 15 years of experience in the air conditioner printed circuit board industry, I have had the privilege to work on numerous projects, especially in the air conditioner printed circuit board and inverter AC PCB sectors. One of the most significant trends I have observed in recent years is the increasing demand for energy-efficient solutions in the new energy sector. This shift has amplified the need for custom-designed air conditioning rigid-flex PCBs to meet the unique challenges of this evolving industry. In this article, we will explore successful case studies that highlight the crucial role of custom rigid-flex PCBs in maximizing efficiency and addressing industry-specific challenges in the new energy sector.

Case Study 1: Enhancing Thermal Management for Inverter AC Systems

Challenge: Inverter air conditioning systems are at the forefront of energy-efficient HVAC solutions. However, their complex design and high-frequency operation present unique challenges for thermal management. Conventional rigid PCBs are limited in their ability to dissipate heat efficiently, leading to increased energy consumption and reduced system reliability.

Solution: One of our clients, a leading manufacturer of inverter AC systems, approached us intending to improve the thermal performance of their control boards. Leveraging our expertise in rigid-flex PCB design, we customized a solution that integrated advanced thermal management techniques. By creating a multilayer AC rigid-flex printed circuit board with strategically placed heat-dissipating materials and high thermal conductivity substrates, we were able to address the heat dissipation challenges inherent in inverter AC systems.

Outcome: The custom rigid-flex PCB design not only significantly improved the thermal performance of the inverter AC PCB systems but also resulted in a notable reduction in energy consumption. Our client reported a 15% increase in energy efficiency, leading to enhanced product competitiveness and customer satisfaction. The successful deployment of this solution showcased the pivotal role of custom rigid-flex PCBs in maximizing the efficiency of air conditioning systems within the new energy sector.

Case Study 2: Optimizing Control Board Functionality for Smart Air Conditioners

Challenge: As the demand for smart air conditioning systems continues to rise, the integration of advanced control and communication features presents a unique set of challenges. Conventional rigid or flexible PCB solutions often struggle to provide the necessary flexibility and reliability required for these complex applications.

Solution: Working closely with a leading player in the smart air conditioning market, we embarked on a project to develop a custom new energy air conditioning PCB solution tailored to address the specific requirements of their advanced control boards. Through a collaborative design process, we created a rigid-flex PCB architecture that seamlessly integrated complex control circuitry with high-speed communication interfaces, while offering the necessary flexibility and durability to withstand the dynamic demands of smart air conditioning systems.

Outcome: The successful deployment of the custom rigid-flex PCB solution resulted in a significant enhancement in the functionality and reliability of the smart air conditioning systems. Our client reported improved system responsiveness, reduced signal interference, and enhanced durability, leading to a noticeable increase in customer satisfaction and product uptake. This case study underscored the critical role of custom rigid-flex PCBs in optimizing the performance of air conditioning systems within the new energy sector.

Case Study 3: Enabling Compact and Efficient PCB Layouts for Air Conditioning Units

Challenge: The trend towards compact and slimmer air conditioning units presents a distinct design challenge for PCB engineers. Traditional rigid or flexible PCBs often struggle to accommodate the spatial constraints and complex interconnections required for these space-constrained applications, leading to compromised efficiency and reliability.

Solution: In collaboration with a prominent air conditioning unit manufacturer, we undertook a custom rigid-flex PCB design project aimed at enabling compact and efficient PCB layouts for their next-generation products. By leveraging innovative rigid-flex technology, we engineered a PCB solution that seamlessly integrated the control and power distribution circuitry, while offering the necessary flexibility to conform to the spatial constraints of the air conditioning unit’s form factor.

Outcome: The successful implementation of the custom air conditioning main PCB design not only enabled our client to achieve their compactness and efficiency goals but also resulted in an overall improvement in system performance. The air conditioning units equipped with the custom rigid-flex AC PCBs exhibited enhanced energy efficiency, reduced electromagnetic interference, and improved reliability, reinforcing the role of custom rigid-flex PCBs in meeting the evolving demands of the new energy sector.

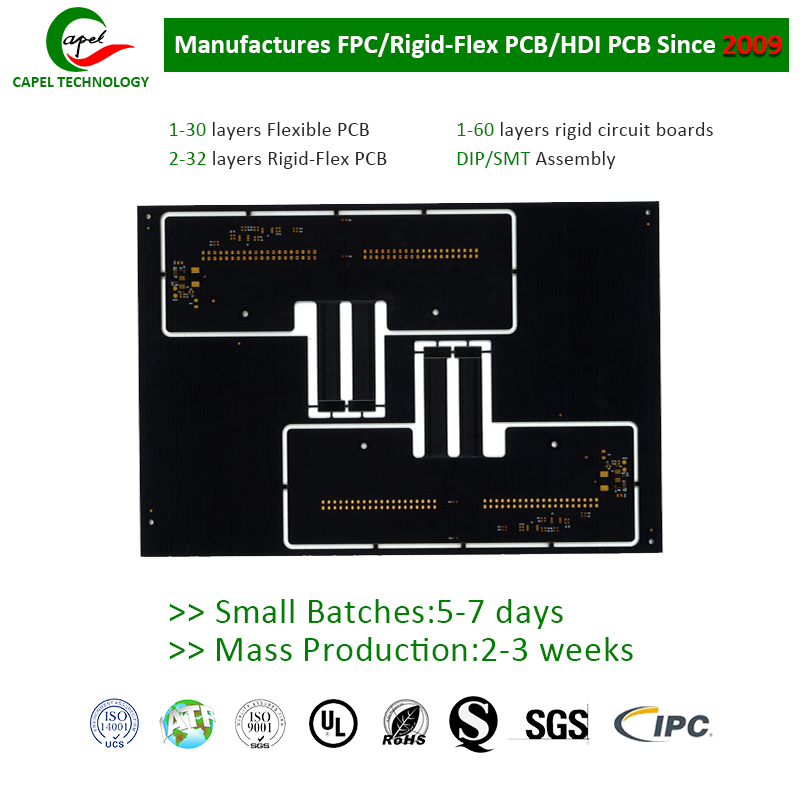

rigid-flex pcb fabrication process

Conclusion

The case studies presented in this article serve as compelling evidence of the pivotal role of custom rigid-flex PCBs in maximizing efficiency and addressing industry-specific challenges in the new energy sector. From enhancing thermal management in inverter AC systems to enabling compact and efficient PCB layouts for air conditioning units, the versatility and customizability of rigid-flex PCB solutions have proven instrumental in driving the advancement of energy-efficient air conditioning technologies.

As the industry continues to push the boundaries of energy efficiency and innovation, the collaboration between PCB engineers and air conditioning manufacturers becomes increasingly essential. By leveraging the expertise and experience of seasoned rigid-flex PCB engineers, air conditioning manufacturers can not only meet the evolving demands of the new energy sector but also gain a competitive edge in the market. Custom rigid-flex air conditioner control board solutions are poised to play a pivotal role in shaping the future of energy-efficient air conditioning systems, and I am proud to be at the forefront of this transformative journey.

In closing, the successful case studies presented in this article underscore the critical importance of custom rigid-flex PCBs in driving efficiency and innovation in the air conditioning industry within the new energy sector. As the demand for energy-efficient solutions continues to grow, air conditioning manufacturers must embrace the potential of custom rigid-flex PCBs as a cornerstone of their product development strategy. Together, we can continue to push the boundaries of efficiency and sustainability in air conditioning technology, ultimately advancing the goals of the new energy sector.

Post time: Dec-25-2023

Back