In this article, we will explore the factors that determine maximum layer count and discuss how Capel leverages its 15 years of experience in the PCB industry to offer 2-32 layer rigid-flex PCB boards.

As technology advances, the demand for more compact and flexible electronic devices continues to increase. The emergence of rigid-flex circuit boards is a solution to meet these needs. They combine the advantages of rigid and flexible PCBs, allowing for greater design flexibility and higher performance. An important aspect to consider when designing a rigid-flex circuit board is the maximum number of layers it can support.

Learn about rigid-flex circuit boards :

Rigid-flex circuit boards are a hybrid of rigid and flexible printed circuit boards. They consist of multiple layers of rigid and flexible materials laminated together to form a single board with integrated electrical connections. This combination of rigidity and flexibility allows the creation of complex designs that fit different form factors.

The number of layers of a rigid-flex circuit board: it will be influenced by a variety of factors

A common question that comes up when discussing rigid-flex circuit boards is: “What is the maximum number of layers in a rigid-flex circuit board?” The number of layers of a rigid-flex circuit board refers to the number of conductive layers it contains. Each layer consists of copper traces and vias that allow electrical signals to flow. The number of layers directly affects the complexity and functionality of the circuit board. Typically, the number of layers in a rigid-flex circuit board can range from two to thirty-two, depending on the complexity of the design and the requirements of the specific application.

The decision on the number of layers in a rigid-flex circuit board is influenced by a variety of factors, including design complexity, space constraints, and the required performance of the electronic device. When determining the optimal number of layers, a balance must be struck between functionality, cost-effectiveness, and manufacturability.

The more layers in a rigid-flex circuit board, the higher the wiring density, which means more circuit components can be accommodated on a smaller board. This is very advantageous when dealing with compact electronic devices as it saves valuable space. Additionally, more layers enhance signal integrity and reduce electromagnetic interference, improving performance and reliability.

However, it is crucial to consider the trade-offs associated with more layers. As the number of layers increases, so does the complexity of the PCB design. This complexity can create challenges during the manufacturing process, including increased opportunities for errors, longer production times and higher costs. Additionally, as the number of layers increases, the flexibility of the board may be compromised. Therefore, it is important to carefully evaluate the specific requirements of the application before determining the maximum number of layers for a rigid-flex circuit board.

Factors affecting the maximum number of layers: Several factors determine the maximum number of layers achievable with a rigid-flex circuit board:

Mechanical Requirements:

The mechanical requirements of the device play a vital role in determining the number of layers. If the equipment needs to withstand high vibrations or requires a specific level of flexibility, the number of layers may be limited to ensure the necessary mechanical integrity.

Electrical Properties:

The required electrical properties also affect the number of layers. Higher layer counts allow for more complex signal routing and reduce the risk of signal interference or crosstalk. Therefore, if a device requires precise signal integrity or high-speed data transmission, a higher layer count may be required.

Space limitations:

Available space within the device or system may limit the number of tiers that can be accommodated. As the number of layers increases, the overall thickness of the rigid-flex circuit board also increases. Therefore, if there are strict space constraints, the number of layers may need to be reduced to meet design requirements.

Capel’s expertise in rigid-flex circuit boards:

Capel is a well-known company with fifteen years of experience in the PCB industry. They specialize in providing high-quality rigid-flex PCBs with a variety of layer options, ranging from 2 to 32 layers. With its expertise and knowledge, Capel ensures that customers receive best-in-class PCBs tailored to their unique requirements.

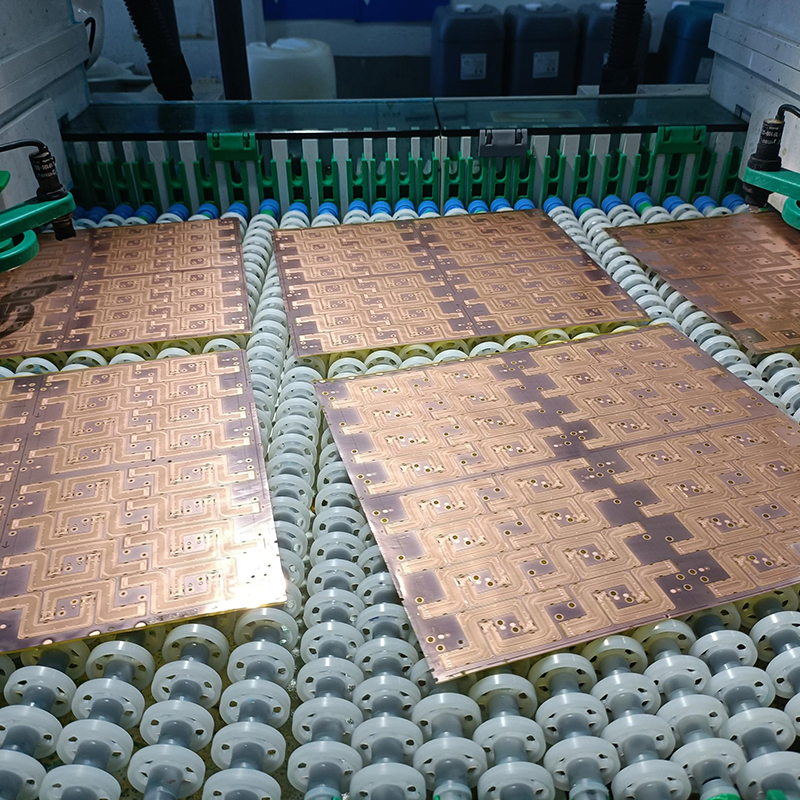

Capel provides 2-32 layer high-precision rigid-flex PCB board:

Capel has 15 years of experience in the PCB industry and focuses on providing high-quality rigid-flex PCB boards. Capel understands the complexities of designing and manufacturing rigid-flex circuit boards, including determining the maximum number of layers. Capel offers a variety of rigid-flex PCB boards with layers ranging from 2 to 32 layers. This broad layer capability allows the design and development of complex circuits with a variety of functions. Whether you need a simple 2-layer board or a highly complex 32-layer board, Capel has the expertise to meet your specific needs.

Quality manufacturing process:

Capel ensures the highest quality standards throughout the entire manufacturing process. They utilize advanced technology and meticulous quality control measures to ensure the performance and reliability of rigid-flex PCB boards. Capel’s team of experienced professionals closely monitors every stage of production to ensure the final product meets or exceeds customer expectations.

Committed to customer satisfaction:

Capel’s commitment to customer satisfaction sets them apart in the PCB industry. Their client-centric approach ensures they listen to their clients’ needs and provide tailor-made solutions to meet their unique needs.

Capel is well versed in meeting these challenges, drawing on its extensive industry experience. Their expert team works closely with clients to understand their design requirements and ensure the best number of layers is selected to meet their specific needs. Capel’s advanced manufacturing facilities and strict quality control measures ensure reliable and high-performance production of rigid-flex PCBs, regardless of the number of layers involved.

In Summary:

As technology continues to advance, the demand for flexible, compact electronic devices continues to grow. Rigid-flex circuit boards have become a popular choice due to their ability to combine the advantages of rigid and flexible PCBs. The maximum number of layers for a rigid-flex circuit board depends on a variety of factors, such as mechanical requirements, electrical performance, and space constraints, complexity and requirements of the application. Capel has 15 years of experience in the PCB industry, providing 2-32 layer rigid-flex PCB boards. Their expertise ensures that high-quality panels are manufactured to customer specifications. Whether you need a two-layer board for a simple application or a complex 32-layer board for high-performance equipment, Capel can meet your requirements. By striking the right balance between functionality, cost-effectiveness and manufacturability, Capel ensures the production of reliable and high-performance PCBs for a variety of applications.Contact Capel today to discuss your project and benefit from their wealth of knowledge and dedication to customer satisfaction.

Post time: Sep-16-2023

Back