Introduce:

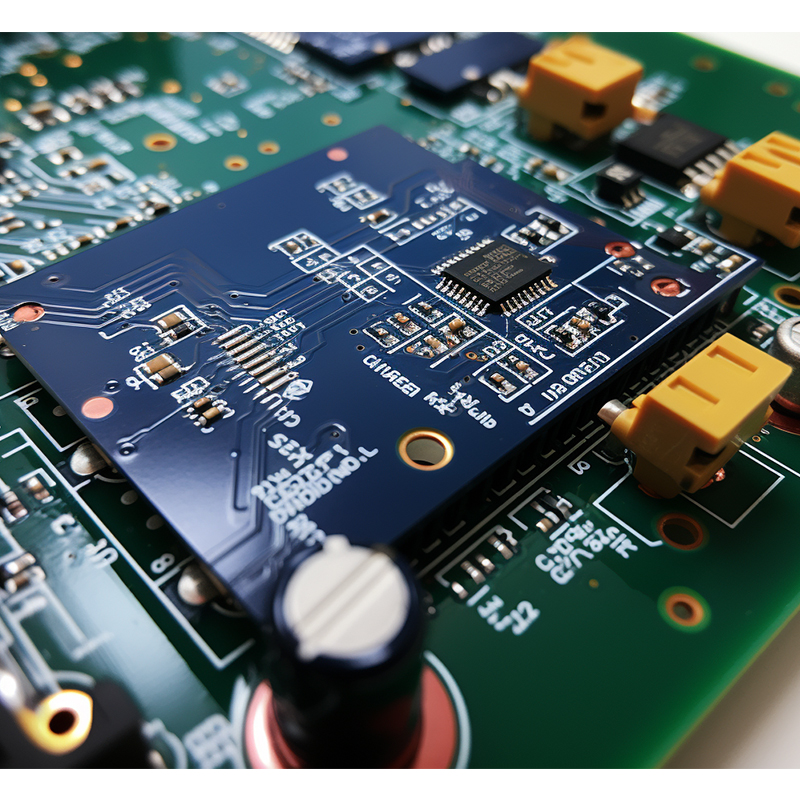

Efficient PCB soldering is critical to the successful assembly and operation of electronic circuits. Proper soldering ensures a reliable electrical connection, which directly affects the performance of the overall circuit. This comprehensive guide will explore the various techniques, types, and techniques involved in PCB soldering. By understanding these aspects, you can make informed decisions when selecting appropriate welding processes and equipment.

PCB soldering overview:

PCB welding, also known as soldering, involves making reliable electrical connections between electronic components and circuit boards. It plays a vital role in ensuring the normal operation of the entire circuit. Different soldering techniques are used in PCB assembly, each with its own benefits and considerations.

Learn about PCB soldering technology:

A. PCB welding process:

In order to achieve a successful weld, it is important to follow a detailed process. This section will outline the step-by-step process of PCB soldering. It will also cover the preparation of PCB components for soldering and outline the necessary tools and equipment.

B. Common PCB soldering techniques:

Through-hole soldering:

Through-hole soldering is a widely used technique that involves soldering components through pre-drilled holes in a circuit board. This section will provide a description of the through-hole soldering method, discuss its advantages and disadvantages, and highlight best practices and applications.

Surface mount soldering:

Surface mount soldering, also known as surface mount technology (SMT) soldering, is commonly used to miniaturize electronic components. This section will provide an overview of SMT soldering technology, its benefits, limitations, and key considerations for successful implementation.

Fine pitch welding:

Soldering fine-pitch components can present unique challenges due to the close pitch of the pins. This section examines the difficulties associated with soldering fine-pitch components and provides tips and precautions for achieving precise solder joints. Additionally, advanced equipment and tools that help achieve precise fine-pitch welding will be discussed.

Welding of the rigid-flex board:

Rigid-flex welding refers to the process of soldering components on a flexible circuit board integrated with a rigid part. This section will introduce the technology behind rigid-flex soldering, discuss the challenges involved, and provide solutions to ensure high-quality solder joints in rigid-flex PCB assemblies.

HDI PCB soldering:

High-density interconnect (HDI) PCBs feature complex designs and high component density. Soldering HDI PCB requires specialized knowledge. This section explores the complexities of soldering HDI PCBs, highlights the expertise required, and discusses the advantages and considerations of HDI PCB soldering.

Tips for successful PCB soldering:

A. Preparation and Planning:

Successful PCB soldering starts with proper preparation and planning. This section discusses the importance of PCB layout and component placement to simplify the soldering process. It will also emphasize the need to select the correct soldering technique based on the PCB design and the importance of the correct use of solder paste.

B. Welding process and equipment selection:

Choosing the correct welding tools and equipment is critical to achieving successful welding results. This section will guide you in determining the appropriate tools and equipment for a specific task. It will also discuss factors to consider when selecting welding materials and emphasize the importance of using appropriate welding temperature profiles.

C. Quality Control and Inspection:

Implementing quality control measures and conducting inspections during the welding process is critical to ensuring reliable solder joints. This section discusses solder joint visual inspection techniques, as well as advanced inspection methods and tools that can be used to evaluate weld quality.

Conclusion:

In summary, this comprehensive guide covers the importance of efficient PCB soldering and the impact that correct soldering has on circuit functionality. By choosing the right soldering process and technique, you can achieve high-quality solder joints. Proper preparation, careful equipment selection, and thorough quality control are the keys to successful PCB soldering. Investing in high-quality soldering equipment and following best practices will yield superior results in PCB assembly.

Post time: Nov-07-2023

Back