For the manufacturing industry, the key factor that determines the success of a company is production capacity. The biggest concern for many companies is whether the factory they choose can meet the needs of large-volume orders. In this blog post, we’ll explore Capel’s flexible PCB and rigid-flex board production capabilities to address the question: What is the factory’s production capacity and is it enough to meet high-volume orders?

Capel is a well-known manufacturer of flexible PCBs and rigid-flex PCBs. With years of industry experience, the company has built a reputation for delivering high-quality products and exceptional customer service. An important aspect that differentiates Capel from its competitors is its impressive production capabilities, allowing them to efficiently handle high-volume orders.

To ensure customer satisfaction, Capel’s production capacity reaches over 45,000 square meters per month. This impressive level of production demonstrates their commitment to meeting the needs of customers requiring high volumes of flexible and rigid-flex PCBs. With this capacity, Capel can meet the needs of a wide range of industries, including consumer electronics, automotive, medical devices and more.

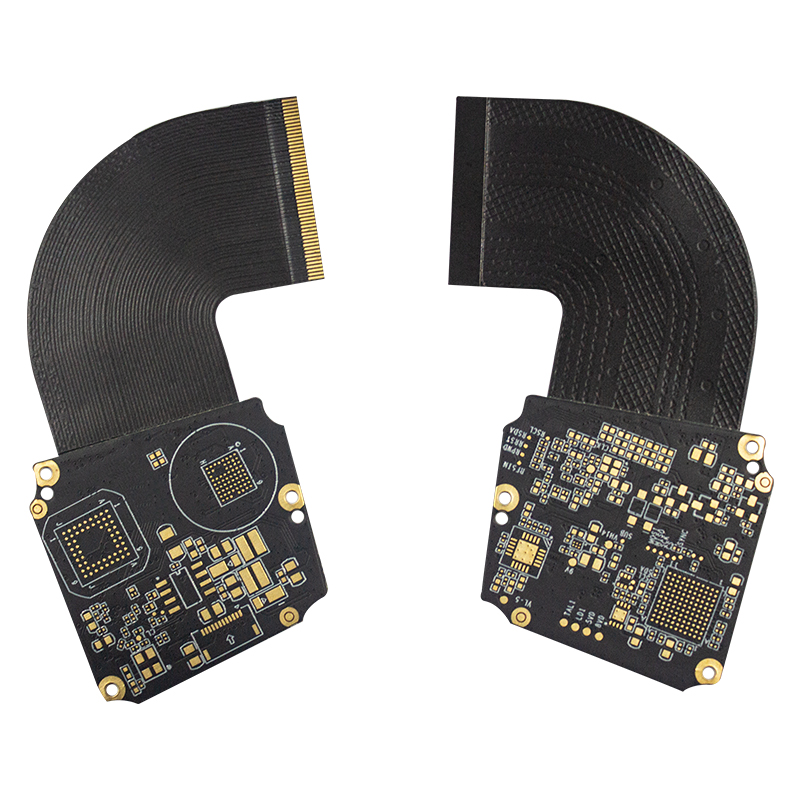

How does Capel achieve such impressive production capacity? The company uses cutting-edge technology and state-of-the-art facilities to achieve efficient and streamlined production processes. From the initial design phase to the final production phase, Capel’s manufacturing operations focus on maximizing output without compromising quality.

One of the reasons for Capel’s high production capacity is its highly skilled and experienced team. The company invests in providing employees with comprehensive training to ensure they are equipped to handle the complexities of PCB production. By combining the expertise of its employees with advanced production technology, Capel can optimize operations and maintain high levels of productivity.

Quality control is another important aspect of Capel’s ability to meet the needs of large-volume orders without compromising product quality. Through strict quality assurance measures, the company ensures that every flexible PCB and rigid-flex PCB that leaves the factory meets the highest standards. Capel understands the importance of providing customers with reliable and durable PCBs, especially when high volume orders are involved.

Additionally, Capel’s commitment to sustainability and environmental responsibility plays an important role in its production capabilities. The company actively works to reduce waste, reduce energy consumption and optimize manufacturing processes to ensure a minimal environmental footprint. By combining production practices with environmentally friendly initiatives, Capel demonstrates their dedication to quality production and environmental stewardship.

All in all, Capel’s flexible PCB and rigid-flex board production capabilities are very commendable. The company’s monthly production capacity exceeds 450,000 square meters, which is enough to meet the needs of large-volume orders. Capel’s focus on advanced technology, skilled labor, strict quality control and sustainable development allows them to stand out in the industry. Whether you are in consumer electronics or automotive, Capel is a reliable partner that can meet your PCB requirements efficiently and professionally.Owning three factories and Leading the PCB industry, Capel now employs more than 1500 workers, over 200 of them being engineers and researchers, and over 100 of them having over 15 years of experience in the PCB industry.We are a comprehensive high-tech enterprise specializing in the research and development, production, and sales of Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single/Double-Sided Circuit Boards, Hollow Boards, HDI Boards, Rogers PCB, rf PCB,Metal Core PCB, Special Process Boards, Ceramic PCB, SMT Assembly, PCB Prototype Service more than 15 years.

Post time: Oct-30-2023

Back