Are you looking for a way to quickly turn around your circuit board prototypes with thermal management? Don’t hesitate any longer! In this blog, we will discuss how to achieve this goal by leveraging the expertise and industry experience of Capel, a leading company specializing in the production of mid- to high-end flex PCB, rigid-flex and HDI PCB boards. With 15 years of experience and continuously upgraded production technology, Capel has the advanced process capabilities needed to turn your circuit board prototypes into reality.

When creating circuit board prototypes, incorporating thermal management features is critical. Thermal management plays a vital role in ensuring optimal performance of electronic devices and preventing overheating. By addressing thermal issues during the prototype stage, you save time and costs associated with rework and potential product failure.

Capel understands the importance of thermal management in circuit board design and provides professional services to help you achieve the results you require. Their team of experts will work closely with you to understand your project needs and guide you through the entire prototyping process.

First, Capel leveraged its extensive experience in flexible PCB production to design the board layout to accommodate thermal management features. Flexible PCBs offer many advantages, including reduced size and weight, increased flexibility, and improved heat dissipation. By leveraging these advantages, Capel ensures your board can effectively manage heat without compromising performance or reliability.

In addition, Capel specializes in rigid-flex PCB production, which combines the advantages of flexible and rigid boards. This unique design increases flexibility and enables the integration of thermal management features in specific areas. Rigid-flex boards are particularly suitable for applications with complex geometric requirements and limited space.

Additionally, Capel’s expertise extends to manufacturing HDI (High Density Interconnect) PCB boards. HDI PCBs feature high-density routing for efficient heat dissipation by optimizing component placement and the conductivity of the board. These boards are ideal for applications that require miniaturization without compromising thermal management capabilities.

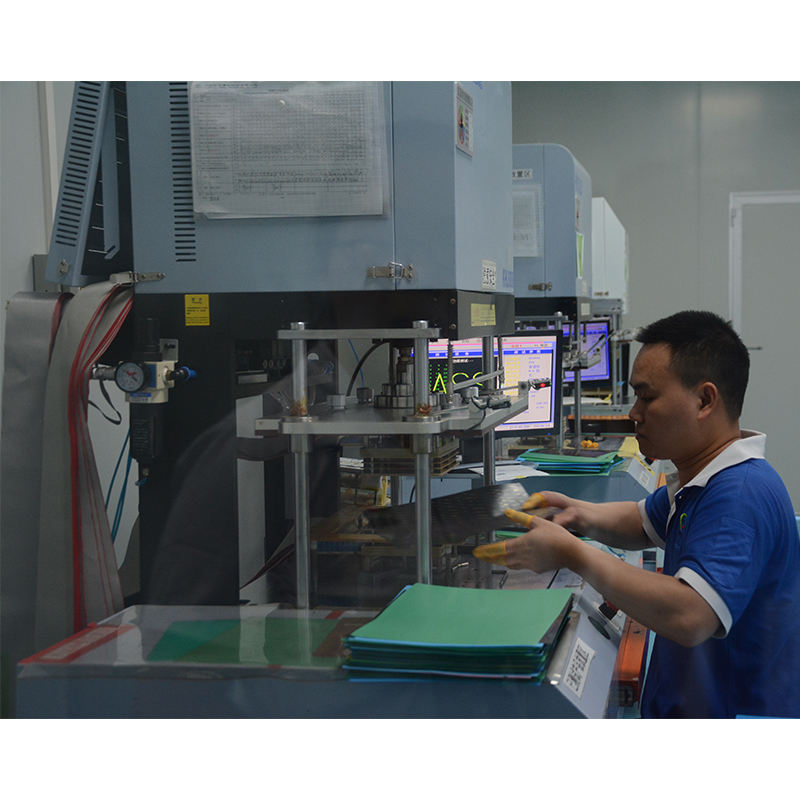

Capel is committed to upgrading production technology and advanced process capabilities to ensure you produce prototypes with the highest precision and attention to detail. With their state-of-the-art facilities and strict quality control measures, you can be confident that your boards will meet your specifications and performance requirements.

In addition to technical expertise, Capel values open communication and collaboration with clients. They understand that the success of your project depends on clear communication and transparent feedback throughout the prototyping process. Capel’s team will work closely with you to provide regular updates and resolve any issues or modifications that may arise.

When you work with Capel, you not only gain access to their industry-leading expertise, but you also benefit from their commitment to providing exceptional customer service. Their team of professionals prioritize customer satisfaction, ensuring your prototyping experience is seamless and efficient.

In conclusion, if you are looking for a quick turnaround circuit board prototype with thermal management capabilities, Capel is your ideal partner. With extensive industry experience, advanced process capabilities and ongoing technological advancements, they have the expertise to turn your project into reality. Whether you need a flexible PCB, rigid-flex PCB, or HDI PCB board, Capel will provide high-quality prototypes that meet your specific requirements. Contact Capel today to start your journey to successful circuit board prototyping.

Post time: Oct-19-2023

Back