Introduce:

As the demand for innovative, efficient battery-powered devices continues to grow, the need for fast, reliable PCB prototyping has become critical. In response to this growing market, Capel, a well-known company with 15 years of expertise in the circuit board industry, provides cutting-edge technology solutions to meet the unique needs of new energy battery customers. This blog explores the importance of rapid PCB prototyping considerations in battery-powered devices, highlighting how Capel’s expertise can contribute to accelerating customer projects and achieving market dominance.

1. The importance of design considerations:

Rapid PCB prototyping plays a vital role in ensuring the successful development and timely market introduction of battery-powered devices. By understanding and implementing specific design considerations, engineers can optimize the performance, reliability and energy efficiency of these devices. This section highlights the impact of ignoring key design considerations and emphasizes the need to integrate them into the PCB prototyping process.

2. Size and shape:

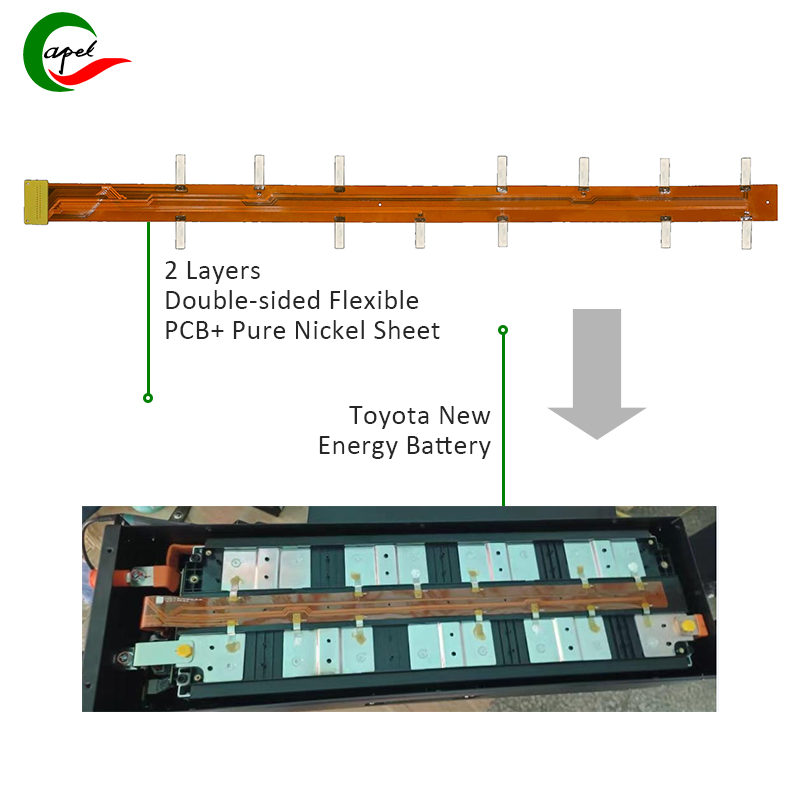

When designing PCB prototypes for battery-powered devices, size and form factor are critical. The compact nature of these devices requires the integration of power-dense components, efficient heat dissipation mechanisms, and suitable circuit board materials. Capel’s extensive experience enables them to deliver PCB prototypes that are not only compact but also capable of accommodating high component density, thus ensuring optimal utilization of the available space.

3. Power consumption and battery life:

Efficient energy management is a key issue for battery-powered devices. Design considerations such as low power consumption, efficient energy harvesting and intelligent power management technology can significantly impact a device’s battery life. Capel’s technical expertise allows them to deliver PCB prototypes that optimize power consumption, maximize battery life and extend device runtime.

4. Signal Integrity and Noise Reduction:

Unwanted signal interference and noise pose significant challenges to battery-powered devices. Poor signal integrity can lead to data corruption, reduced transfer speeds, and degraded performance. Therefore, design considerations aimed at minimizing electromagnetic interference (EMI), optimizing trace routing, and employing proper grounding techniques are critical. Capel’s expert implementation of such design considerations ensures superior signal integrity, resulting in flawless performance in battery-powered devices.

5. Thermal management:

Battery-powered devices often generate large amounts of heat, which if not managed properly can lead to reduced device performance, premature component failure and safety hazards. Design considerations include efficient heat dissipation, correct component placement, and adequate thermal vias, which are critical to maintaining the overall thermodynamic stability of the device. Capel’s expertise in thermal management allows them to deliver best-in-class PCB prototypes that can withstand harsh thermal conditions and ensure long-term device reliability.

6. Component selection and placement:

Component selection and placement play a vital role in the overall functionality and reliability of a battery-powered device. Design considerations related to component selection include factors such as power consumption, temperature tolerance, and compatibility. Capel’s extensive technical knowledge enables them to provide comprehensive support in component selection, ensuring optimal performance and seamless integration in PCB prototypes.

7. Environmental considerations:

Battery-powered devices often operate in challenging environments, including extremes of temperature, humidity, and mechanical stress. Design considerations combine environmental regulations and ruggedness to achieve equipment durability and continued performance. Capel’s meticulous attention to environmental factors ensures that its PCB prototypes meet the necessary reliability standards, making them ideal for battery-powered devices that need to withstand harsh conditions.

In conclusion:

Design considerations for rapid PCB prototyping must be an integral part of the development process for battery-powered devices. With Capel’s superior expertise and experience in providing reliable circuit board prototyping services to new energy battery customers, companies can accelerate their projects, seize market opportunities, and gain competitive advantage. By prioritizing key design considerations such as size, power consumption, signal integrity, thermal management, component selection and environmental factors, battery-powered devices can truly differentiate themselves in performance, reliability and longevity.

Post time: Oct-18-2023

Back