In this blog post, we will explore some effective strategies to ensure the reliability and durability of flexible circuit boards.

In today’s technologically advanced world, flexible circuit boards have become key components in various electronic devices. These thin, lightweight, and versatile circuit boards offer many advantages over rigid circuit boards. However, while flexible circuit boards offer enhanced flexibility and convenience, ensuring their reliability and durability can be a challenging task.

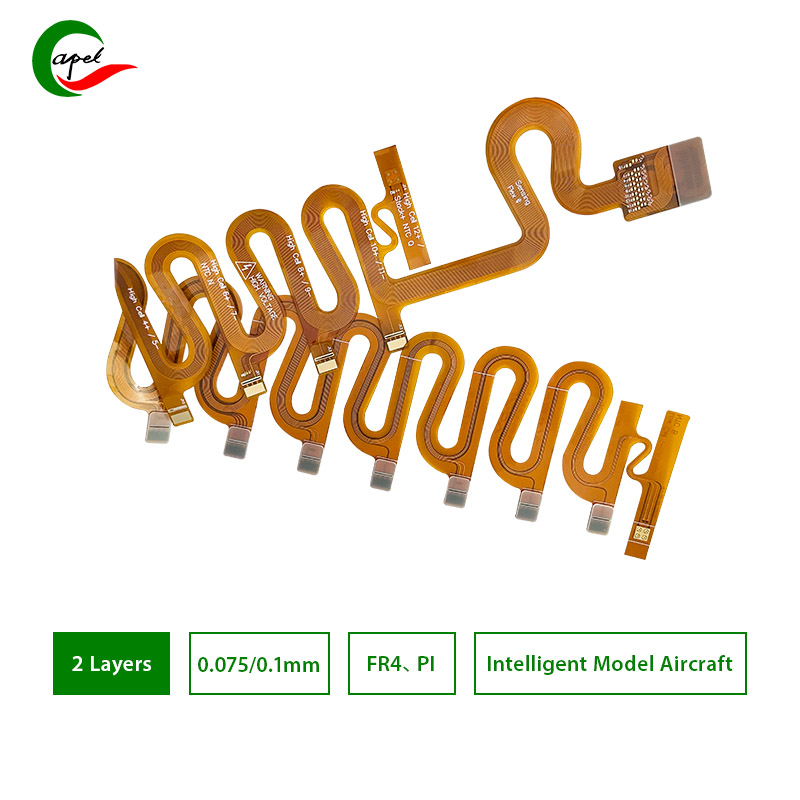

1. Design flexibility

One of the first factors to ensure the reliability and durability of flexible circuit boards is to consider flexibility during the design phase. Designers should focus on creating a layout that allows the board to bend and bend without causing any damage. Component placement, trace routing, and material selection should be optimized to withstand repeated bends and bends. Adhering to industry standards and guidelines for flexible circuit board design is critical to ensuring reliable performance.

2. Material selection

Choosing the right materials is another critical aspect of ensuring the reliability and durability of flexible circuit boards. Material selection should consider the specific requirements of the application, such as temperature extremes, moisture resistance, and chemical exposure. Materials should be selected with excellent mechanical properties, such as high flexibility, low coefficient of expansion and good adhesive properties, to withstand the rigors of repeated bending and flexing. Thorough research of available materials and consultation with experts can help make an informed decision.

3. Component placement

Proper component placement plays an important role in ensuring the reliability and durability of flexible circuit boards. Strategically mounted components can minimize stress concentrations during bending and bending. Components that may be subject to mechanical stress or strain should be located away from areas that may be subject to repeated bending. Additionally, ensuring adequate clearance between components and avoiding overcrowding can prevent damage from contact between adjacent components. Component arrangement should be carefully considered to maintain the integrity of the flexible circuit board.

4. Bending radius

The bend radius of a flexible circuit board is the smallest radius at which it can be safely bent without causing damage. It is critical to determine and adhere to recommended bend radii during the design and manufacturing process. Bending a circuit board beyond its recommended bend radius can cause cracks to form in the conductive traces and insulation, compromising reliability and durability. By adhering to the specified bending radius, the risk of damage can be significantly reduced, ensuring the longevity of the flexible circuit board.

5. Environmental considerations

Understanding the environmental conditions in which flexible circuit boards are used is critical to ensuring their reliability and durability. Factors such as extreme temperatures, humidity, vibration, and exposure to chemicals can affect the performance and longevity of circuit boards. Conducting thorough environmental testing and analysis can help identify potential weaknesses and take appropriate steps to strengthen the board against these conditions. Coatings, encapsulation, and conformal coatings can be used to protect circuits from moisture, contaminants, and other environmental factors.

6. Strict testing and quality control

Employing comprehensive testing and quality control procedures is critical to ensuring the reliability and durability of flexible circuit boards. Thoroughly testing a circuit board’s functionality, electrical performance, and mechanical robustness can help identify any issues or weaknesses that could lead to failure. Implementing strict quality control measures throughout the manufacturing process, including inspections, audits, and compliance with industry standards, can greatly improve the reliability of flexible circuit boards.

In summary, ensuring the reliability and durability of flexible circuit boards is critical for today’s electronic devices. By considering flexibility during the design phase, selecting appropriate materials, strategically placing components, adhering to recommended bend radii, understanding environmental factors, and conducting thorough testing and quality control, manufacturers can increase the service life and performance of these important components. By following these strategies, we can ensure that flexible circuit boards continue to revolutionize the electronics industry by providing reliable, durable solutions for a wide range of applications.

Post time: Sep-21-2023

Back