Introduction

Capel is at the forefront of the electronics industry and has become a reliable and innovative player in printed circuit board (PCB) manufacturing. With 15 years of experience and a commitment to utilizing advanced technology, Capel has earned a strong reputation for its quality products. In this blog post, we will explore whether Capel indeed developed PCB manufacturing equipment independently. Through investments in cutting-edge production equipment and a team of highly skilled professionals, Capel has become a company that embraces technology and delivers superior circuit boards.

Learn about Capel’s stand-alone PCB manufacturing equipment

In today’s fiercely competitive market, having the ability to independently develop PCB manufacturing equipment is priceless. It not only signals the company’s commitment to self-reliance but also demonstrates its ability to adapt to industry needs. Speaking of Capel, one might wonder whether they have this independent capability or whether they rely on partners or outsourcing.

Capel has invested heavily in research and development, allowing them to design and produce their own PCB manufacturing equipment. This commitment to innovation allows them to create cutting-edge machines specifically tailored to their needs. With years of experience in the field, Capel understands the nuances of PCB manufacturing and can fine-tune its equipment to meet the highest quality standards.

Advanced fully automatic production equipment

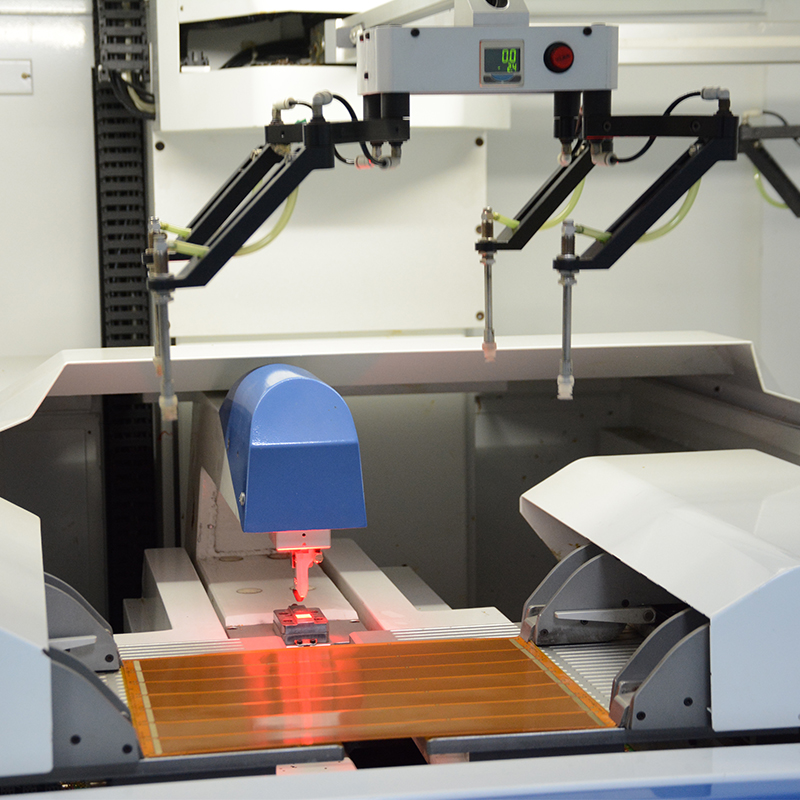

One of the key factors that differentiates Capel from its competitors is its use of advanced, fully automated production equipment. As the demand for precise, efficient circuit boards continues to increase, Capel recognizes the importance of investing in state-of-the-art machinery.

Capel’s fully automated production equipment enables a seamless manufacturing process. The integration of robotics, advanced software and machine learning algorithms ensures increased accuracy, productivity and a reduced margin of error. Additionally, this setup provides flexibility in terms of production volumes and customization, allowing Capel to meet a variety of customer requirements.

The company’s carefully designed production lines cover multiple stages, including printing, solder mask application, component placement, soldering, and testing. Each process is strictly monitored to ensure consistent quality and compliance with industry standards. Capel’s investment in such advanced equipment demonstrates its commitment to staying at the forefront of technological advancement and delivering high-quality circuit boards.

Benefits of independently developing equipment

Having independently developed PCB manufacturing equipment provides companies like Capel with numerous advantages. First and most importantly, it gives them full control over the entire production process, from design to assembly. This level of control ensures that Capel can consistently deliver high-quality and reliable circuit boards to its customers.

In addition, independently developed equipment gives Capel the flexibility to continuously improve and refine its manufacturing processes. Feedback from customers and industry professionals helps them identify potential areas for improvement, allowing them to further optimize their production lines. This agility to adapt to changing market needs and customer requirements helps Capel maintain a competitive advantage.

Conclusion

Capel’s commitment to independently developing PCB manufacturing equipment sets them apart in the electronics industry. With 15 years of experience and a reputation for using cutting-edge technology, Capel has firmly established itself as a leader in PCB manufacturing. Their investment in advanced fully automated production equipment, coupled with a dedicated team of professionals, ensures that Capel consistently provides high-quality circuit boards to customers in various industries.

By developing its own manufacturing equipment, Capel demonstrates a commitment to quality, reliability, and innovation. This independent approach allows them to fully control the production process, optimize productivity, and meet the specific needs of their customers. With continued investment in R&D, Capel will undoubtedly continue to push the boundaries of PCB manufacturing and maintain its position as the market leader.

Post time: Nov-05-2023

Back