In this blog post, we take an in-depth look at the technical specifications of rigid-flex PCBs and explore how they are changing the world of electronics.

In the ever-evolving field of electronic devices, innovation has become the cornerstone of success. Electronics manufacturers are constantly striving to improve device performance, enhance functionality, and reduce size. To meet these demands, engineers and designers are turning to a breakthrough technology called rigid-flex PCBs. Offering unparalleled flexibility and reliability, these advanced circuit boards have revolutionized the electronics industry, making them an integral part of the development of modern devices.

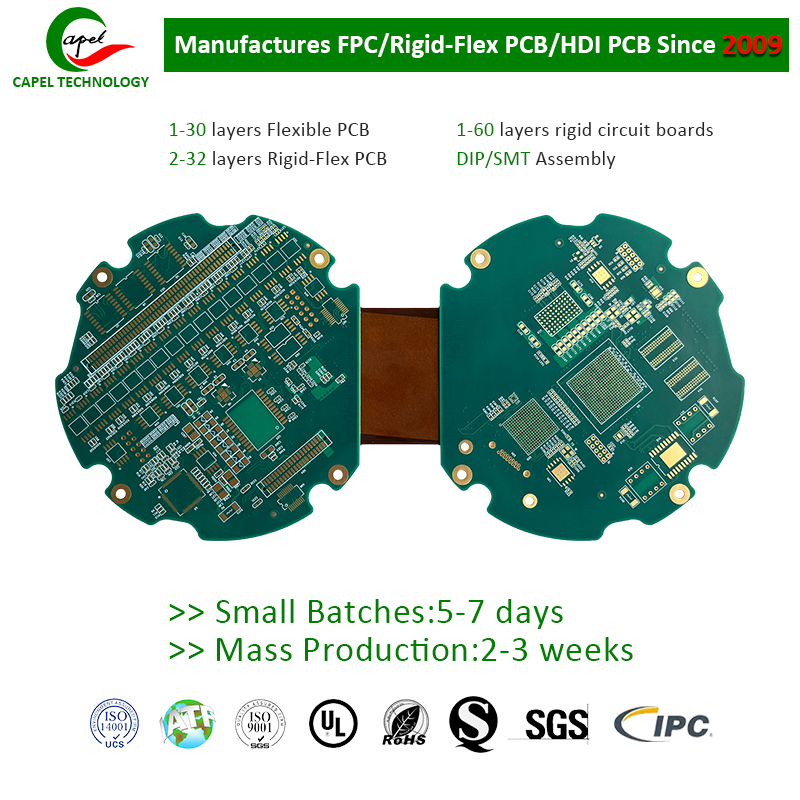

Rigid-flex PCB, also known as flex-rigid PCB, combines the advantages of rigid and flexible circuit boards into a compact unit. These boards are composed of flexible substrates that allow circuitry to bend, twist, and conform to various form factors, while rigid sections provide stability and structural support to the overall design. This unique combination provides unparalleled design freedom, allowing engineers to create devices that were once unimaginable.

One of the key technical specifications of rigid-flex boards is their multi-layer structure. Unlike traditional rigid panels, which consist of a single layer, rigid-flex panels can accommodate multiple layers, which significantly increases design possibilities. The ability to have different layers on different areas of the board allows efficient use of available space, making rigid-flex PCBs ideal for small electronic devices.

The multi-layer structure of rigid-flex PCB also facilitates the integration of complex circuits. Engineers can now incorporate complex designs, such as high-density interconnects and fine-pitch components, into their devices without sacrificing performance or reliability. This groundbreaking capability opens up avenues for the development of cutting-edge technologies such as wearables, medical devices and even flexible displays.

In addition, the mechanical durability and reliability of rigid-flex PCBs are excellent. Flexible substrates are made of polyimide material, known for its excellent thermal stability, chemical resistance and mechanical strength. This rugged composition enables rigid-flex PCBs to withstand harsh environmental conditions, including extreme temperatures, vibration and shock. As a result, devices using rigid-flex PCBs can operate flawlessly in challenging environments, thereby expanding the scope of applications across industries.

Using rigid-flex PCBs in electronic devices can also improve signal integrity and reduce electromagnetic interference (EMI). Flexible substrates help dampen vibrations and reduce signal losses, ensuring reliable and efficient transmission of electrical signals. In addition, rigid-flex PCBs provide superior EMI shielding, reducing the risk of electromagnetic radiation interfering with nearby components or affecting the overall performance of the device. This makes rigid-flex PCBs ideal for high-frequency applications such as wireless communication systems and automotive electronics.

Rigid-flex PCBs not only improve the performance and reliability of electronic devices, but also help save costs during the manufacturing process. Integrating multiple functions onto a single board reduces the need for additional components and simplifies assembly, thereby lowering production costs and increasing productivity. Additionally, the compact nature of rigid-flex PCBs allows for smaller device footprints, saving material and packaging costs.

In summary, rigid-flexible PCBs have revolutionized the electronics world by providing advanced technical specifications that meet the needs of modern devices. These flexible and reliable circuit boards offer design flexibility, multi-layer construction, mechanical durability, improved signal integrity, reduced EMI and cost savings. By using rigid-flex PCBs, engineers and manufacturers can push the boundaries of innovation and deliver breakthrough technologies to the market. As the electronics industry continues to evolve, it is clear that rigid-flexible PCBs will play a key role in shaping the future of electronic devices.

Post time: Oct-11-2023

Back