In today’s dynamic and technology-driven world, the demand for smaller, more flexible electronic devices is growing. To meet these changing needs, the printed circuit board (PCB) industry has come up with innovative solutions such as flexible PCBs and semi-flexible PCBs. These advanced circuit boards revolutionize industries by offering unprecedented design and manufacturing possibilities. In this blog, we’ll dive into the circuit board wars and compare semi-flexible PCBs vs. flexible PCBs to help you make an informed decision for your next project.

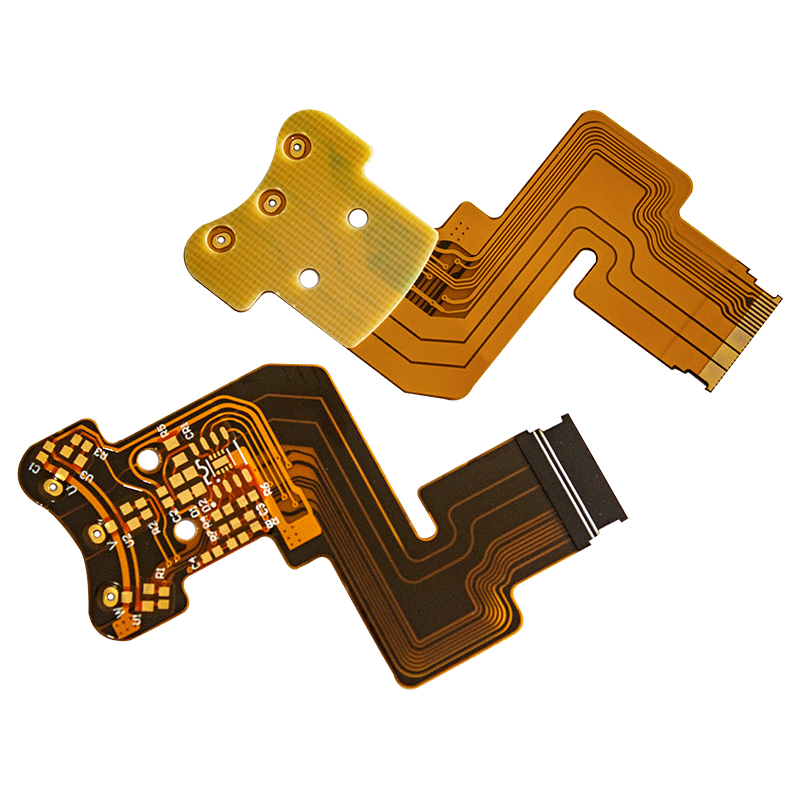

What is semi-flexible PCB?

Semi-flexible PCB, short for semi-flexible printed circuit board, is a hybrid solution that combines the characteristics of rigid and flexible PCBs. They offer moderate flexibility and are ideal for applications requiring rigidity and limited flexibility. Semi-flexible PCBs offer a compromise between the two worlds, giving manufacturers and designers alike the best of both worlds.

Advantages of semi-flexible PCB:

Design flexibility: Semi-flexible PCBs give designers the freedom to create complex shapes and designs that are not possible with rigid PCBs. This flexibility enables manufacturers to optimize the use of available space while ensuring the required mechanical and electrical connections.

Improved reliability: Compared with rigid PCBs, semi-flexible PCBs have excellent resistance to bending, vibration and mechanical stress. This enhanced durability makes them suitable for applications where circuit boards may experience moderate bending or bending during operation.

Cost-effectiveness: Semi-flexible PCBs are generally more cost-effective compared to fully flexible PCBs. Without the need for extensive use of flexible materials, manufacturers can balance budget constraints and design requirements.

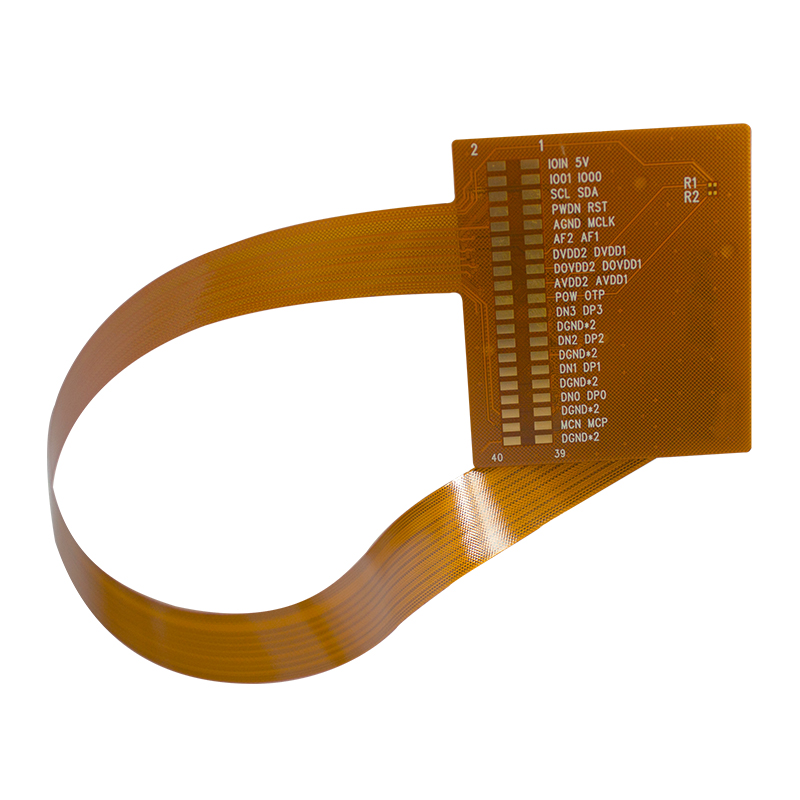

What is a flexible PCB?

Flexible PCBs or flexible printed circuit boards are designed to provide maximum flexibility, allowing them to bend, twist and fold without damaging the board or the components mounted on it. They are made from flexible materials such as polyimide and have excellent electrical and thermal properties.

Advantages of flexible PCB:

Space saving: Flexible printed circuit boards can be manufactured to fit into small spaces and conform to irregular shapes, contributing to the miniaturization and compactness of electronic devices. This feature is crucial for modern electronics, where reducing size and weight is critical.

Reliable performance: Flexible PCB can resist mechanical stress, vibration and thermal changes, making it highly reliable in challenging environments. They excel in applications where shock resistance and durability are critical.

Enhance signal integrity: Flexible PCB has excellent electrical properties, including lower capacitance and impedance, allowing for precise signal transmission and reduced signal loss. This is especially beneficial for high-frequency applications where maintaining signal integrity is critical.

Which one is right for you?

Choosing between semi-flexible PCBs and flexible PCBs depends on a variety of factors, including design requirements, application, budget, and manufacturing constraints. Both types of PCBs have unique advantages and considerations.

If your project requires a moderate amount of flexibility while still requiring some rigidity, a semi-flexible PCB may be the best choice. They offer design flexibility, improved durability and cost-effectiveness.

On the other hand, if miniaturization, space saving and maximum flexibility are crucial to your application, then flexible PCBs will be ideal. They provide excellent reliability, enhanced signal integrity, and allow complex designs.

As technology continues to advance, the need for flexible and adaptable electronic devices becomes even more apparent. Semi-flexible PCBs and flexible PCBs provide innovative solutions to the need for smaller, lighter, and stronger circuit boards. Choosing between these two options depends on your design requirements, application, and budget constraints. Consulting a trusted PCB manufacturer like Capel, a leader in the flexible PCB industry since 2009, can help you make informed decisions and ensure the success of your project. So, keep exploring the possibilities and create groundbreaking electronic devices with the circuit board battle (semi-flexible PCB vs. flexible PCB).

Post time: Sep-12-2023

Back