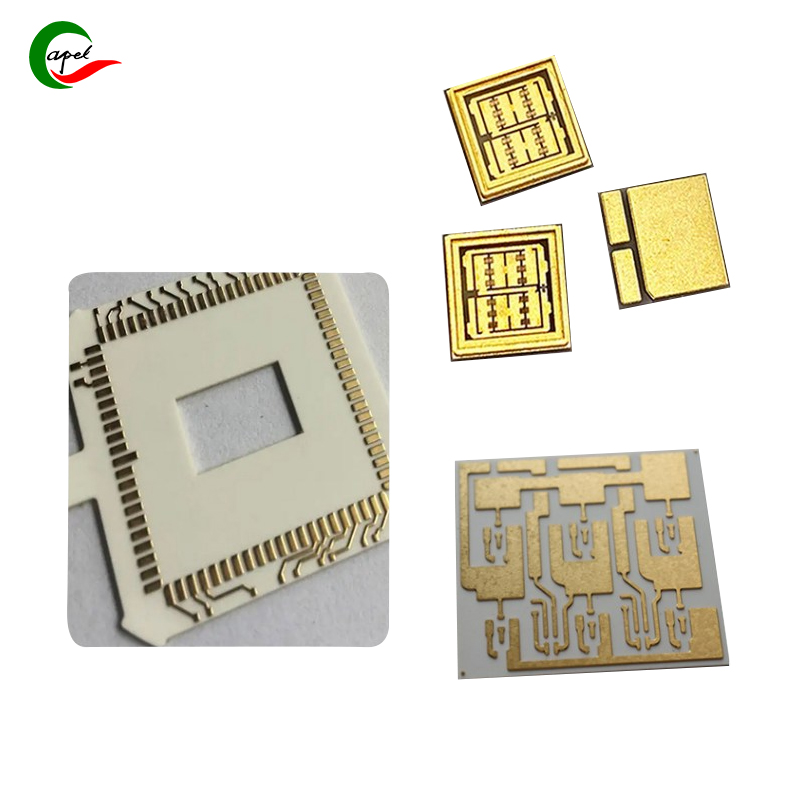

In this blog post, we will explore the different types of ceramic circuit board designs and their unique features.

Ceramic circuit boards are becoming increasingly popular due to their many advantages over traditional circuit board materials such as FR4 or polyimide. Ceramic circuit boards are becoming the first choice for various applications due to their excellent thermal conductivity, high temperature resistance and good mechanical strength. As demand increases, so does the variety of ceramic circuit board designs available in the market.

1. Alumina-based ceramic circuit board:

Aluminum oxide, also known as aluminum oxide, is a material widely used in ceramic circuit boards. It has excellent electrical insulation properties and is suitable for applications requiring high dielectric strength. Alumina ceramic circuit boards can withstand high temperatures, making them suitable for use in high-power applications such as power electronics and automotive systems. Its smooth surface finish and low coefficient of thermal expansion make it ideal for applications involving thermal management.

2. Aluminum nitride (AlN) ceramic circuit board:

Aluminum nitride ceramic circuit boards have superior thermal conductivity compared to alumina substrates. They are commonly used in applications that require efficient heat dissipation, such as LED lighting, power modules, and RF/microwave equipment. Aluminum nitride circuit boards excel in high frequency applications due to their low dielectric loss and excellent signal integrity. Additionally, AlN circuit boards are lightweight and environmentally friendly, making them a suitable choice for various industries.

3. Silicon nitride (Si3N4) ceramic circuit board:

Silicon nitride ceramic circuit boards are known for their excellent mechanical strength and thermal shock resistance. These panels are typically used in harsh environments where extreme temperature changes, high pressures, and corrosive substances are present. Si3N4 circuit boards find applications in industries such as aerospace, defense, and oil and gas, where reliability and durability are critical. In addition, silicon nitride has good electrical insulating properties, making it an excellent choice for high-power applications.

4. LTCC (low temperature co-fired ceramic) circuit board:

LTCC circuit boards are manufactured using multilayer ceramic tapes that are screen-printed with conductive patterns. The layers are stacked and then fired at relatively low temperatures, creating a highly dense and reliable circuit board. LTCC technology allows passive components such as resistors, capacitors and inductors to be integrated within the circuit board itself, allowing for miniaturization and improved performance. These boards are suitable for wireless communications, automotive electronics, and medical devices.

5. HTCC (high temperature co-fired ceramic) circuit board:

HTCC circuit boards are similar to LTCC boards in terms of manufacturing process. However, HTCC boards are fired at higher temperatures, resulting in increased mechanical strength and higher operating temperatures. These boards are commonly used in high-temperature applications such as automotive sensors, aerospace electronics, and downhole drilling tools. HTCC circuit boards have excellent thermal stability and can withstand extreme temperature cycling.

In summary

Different types of ceramic circuit boards are designed to meet a wide range of industry-specific needs. Whether it is high-power applications, efficient heat dissipation, extreme environmental conditions or miniaturization requirements, ceramic circuit board designs can meet these requirements. As technology continues to advance, ceramic circuit boards are expected to play a vital role in enabling innovative and reliable electronic systems across industries.

Post time: Sep-25-2023

Back