Discover the critical role of proper layout and routing in determining the performance and functionality of 4-layer flexible printed circuits (FPCs). Gain valuable insights into the fundamental principles and best practices for achieving optimal 4-layer FPC layout and routing Develop high-performance, reliable electronic designs

Introduce

Flexible printed circuits (FPCs) have revolutionized the electronics industry, providing unparalleled design flexibility and space-saving advantages. In this article, we’ll delve into the critical role of proper layout and routing in determining the performance and functionality of a 4-layer FPC. Understanding the fundamentals of 4-layer FPC layout and routing is critical for engineers and designers to achieve optimal performance and reliability in electronic designs.

Introduction to 4-layer FPC Flex PCB

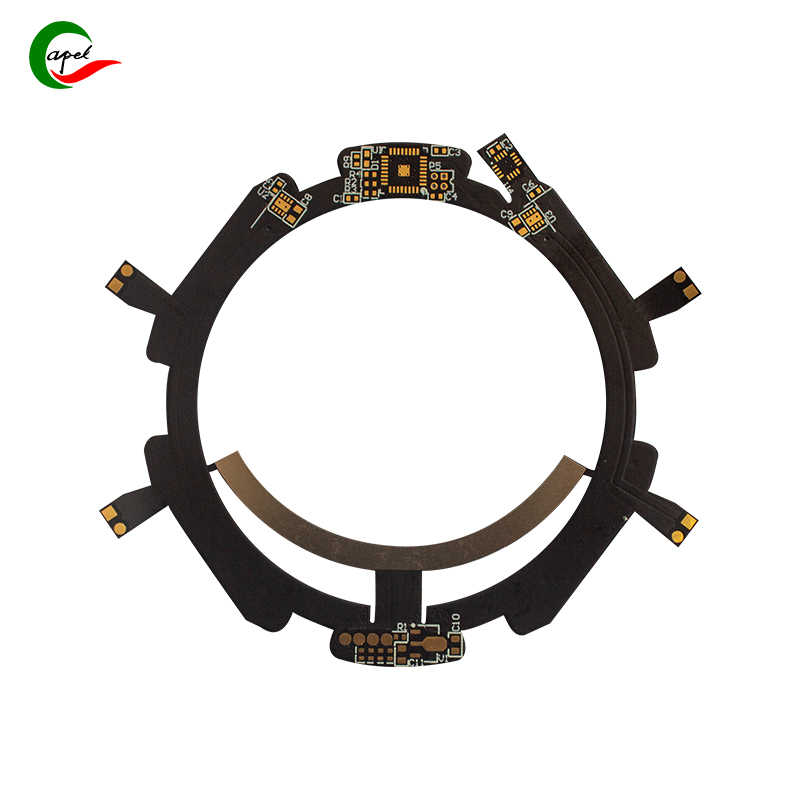

4-Layer Flexible Printed Circuit (FPC) is a special type of printed circuit board that offers more functionality and versatility than traditional rigid boards. Designed to support complex electronic devices and systems, 4-layer FPC provides compact, lightweight solutions for modern electronics ranging from consumer devices to industrial applications.

The importance of proper layout and routing

Ensuring proper layout and routing is critical to unlocking the full potential of 4-layer FPCs. Every aspect of the design, from component placement to signal paths, plays a critical role in determining the overall performance and reliability of the FPC.

Understand 4-layer FPC layout

Key considerations when designing a 4-layer FPC layout

When designing a 4-layer FPC layout, several key factors must be considered to achieve optimal performance. These include signal integrity, power distribution, thermal management and the overall mechanical robustness of the circuit. Engineers and designers need to carefully analyze and plan the layout to ensure these considerations are met.

Factors Affecting 4-Layer FPC Layout Performance

Various factors such as high-speed signals, noise, and interference can affect the performance and reliability of FPC layouts. Understanding and mitigating these factors is critical to ensuring the functionality and stability of a 4-layer FPC design.

Best practices for achieving optimal 4-layer FPC layout

To achieve an optimal layout for a 4-layer FPC, it is critical to follow best practices for component placement, routing, and stack-up design. Proper utilization of design tools and simulation techniques can help optimize the layout to achieve the desired performance requirements.

Master 4-layer FPC wiring

The importance of correct routing in 4-layer FPC

Proper routing plays an important role in ensuring signal integrity, minimizing crosstalk, and managing impedance in a 4-layer FPC. Engineers must carefully plan and execute the layout of the FPC to meet these technical requirements.

Common Challenges of 4-Layer FPC Cabling

Challenges such as signal skew, length matching, and electromagnetic interference (EMI) can affect the routing of 4-layer FPCs, causing potential performance issues. Identifying and solving these challenges is critical to successful FPC design.

Strategies for Effective 4-Layer FPC Routing

Utilizing differential pairs, avoiding sharp corners, and combining signal reference planes are some strategies and techniques for efficient routing in 4-layer FPC. Understanding and applying these techniques can significantly improve the overall performance and reliability of a circuit.

Integrated 4-layer FPC placement and routing

Interrelationship between Placement and Routing

The layout and routing of a 4-layer FPC are closely linked, and changes on one side will have a cascading effect on the other. Engineers must understand this interrelationship to make informed design decisions and optimize FPC performance and reliability.

How to ensure seamless integration of layout and routing in 4-layer flexible PCB

Achieving seamless integration of place and route in a 4-layer FPC requires collaboration, signal path optimization, and the use of design verification tools. By utilizing these methods, engineers can ensure that placement and routing are coordinated to meet design requirements.

Successful integration case studies

Practical examples of successful integration of place and route in 4-layer FPCs demonstrate its positive impact on performance and functionality. These case studies provide valuable insights into best practices and methods for achieving optimal placement and routing in 4-layer FPC designs.

4-Layer FPC Manufacturing Process

In conclusion

Review the importance of proper layout and routing in 4-layer FPC

The critical role of placement and routing in determining the performance and reliability of a 4-layer FPC cannot be overstated. By paying careful attention to these aspects, engineers and designers can unleash the full potential of FPC technology and achieve superior electronic designs.

Final thoughts on achieving optimal 4-layer flexible printed circuit board layout and routing

In summary, achieving optimal placement and routing in a 4-layer FPC design requires a thorough understanding of the technical considerations and best practices outlined in this article. By applying these principles, engineers and designers can create high-performance, reliable, and efficient 4-layer FPCs that meet the needs of modern electronics and technology.

In summary, proper layout and routing of a 4-layer FPC is critical to ensuring optimal performance, functionality, and reliability. With the practical guidance and insights presented in this article, electronics industry professionals can enhance their understanding and approach to 4-layer FPC design, resulting in improved products and a better user experience.

Post time: Mar-01-2024

Back