Introduce:

In today’s digital age, technological advancements are rapidly transforming industries around the world. With the introduction of smart manufacturing and data management systems, manufacturing processes have undergone revolutionary changes. The printed circuit board (PCB) industry has also undergone major transformations due to technological advancements. In this blog post, we will explore whether Capel can provide smart manufacturing and data management capabilities for PCB circuit boards.

1. Understand PCB circuit boards:

Before delving into the intersection of PCB circuit board smart manufacturing and data management, it is crucial to grasp the concept of PCB itself. PCBs are the backbone of modern electronic devices, providing a platform for interconnecting various electronic components. PCBs have grown in complexity over the years, requiring efficient manufacturing processes and flawless data management.

2. Intelligent manufacturing in PCB industry:

Smart manufacturing leverages advanced technologies such as artificial intelligence (AI), the Internet of Things (IoT), robotics, and automation to streamline production processes, reduce errors, and optimize operational efficiency. As PCBs become more and more complex, Capel, as an innovator in this field, has recognized the importance of smart manufacturing in PCB production.

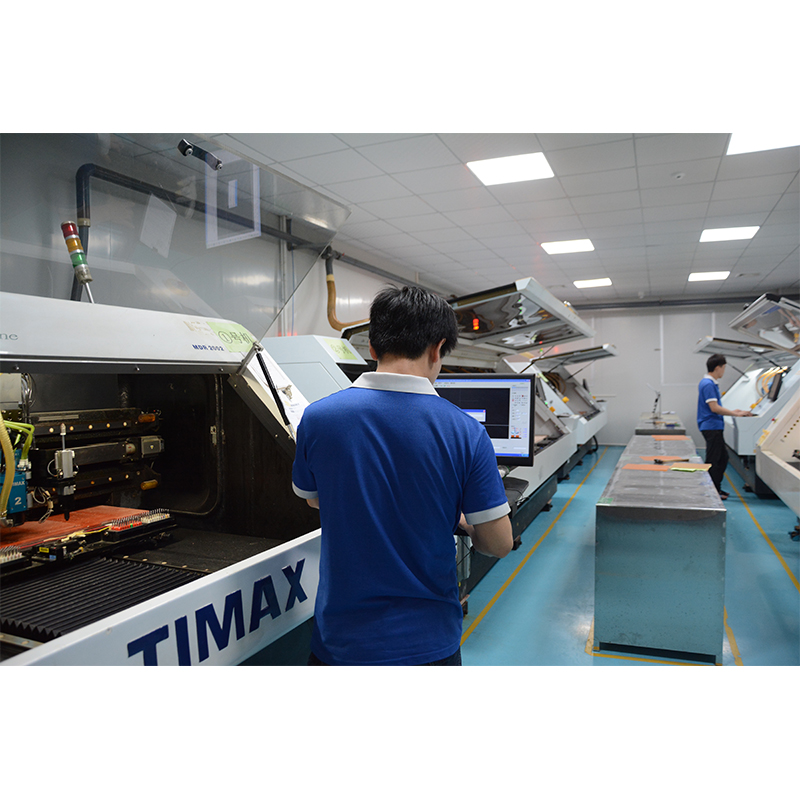

2.1 Robot automation:

Capel integrates robotic automation into manufacturing processes to increase precision and accuracy. Robots can handle delicate PCB components, ensuring potential human error is eliminated. Additionally, AI-powered robots can optimize production lines by identifying bottlenecks and streamlining workflows.

2.2 Internet of Things (IoT) integration:

Capel harnesses the power of IoT to connect its machinery and equipment, enabling real-time data collection and analysis. This connection enables continuous monitoring of the manufacturing process, ensuring timely detection of any anomalies or equipment failures. By leveraging IoT, Capel ensures a more agile and responsive manufacturing workflow.

3. Data management in PCB industry:

Data management covers the systematic organization, storage and analysis of data throughout the PCB production cycle. Efficient data management is critical for tracking product quality, identifying areas for improvement, and ensuring regulatory compliance. Capel’s approach to data management sets them apart from traditional manufacturers.

3.1 Real-time data analysis:

Capel has implemented an advanced data analytics system that can process large volumes of manufacturing data in real time. These analytics enable teams to extract valuable insights to make quick decisions and proactively resolve issues. By identifying patterns and trends, Capel can continuously optimize production quality and efficiency.

3.2 Quality Assurance and Traceability:

Capel prioritizes quality assurance by capturing data at every step of the manufacturing process. This ensures full traceability of the product, allowing for an efficient recall procedure if required. By keeping detailed records of production data, Capel assures customers of robust quality control and the ability to promptly correct any potential issues.

4. Capel’s advantages:

Capel combines smart manufacturing and data management to provide numerous advantages for PCB circuit board production.

4.1 Improve efficiency and accuracy:

Through robotic automation and artificial intelligence-driven systems, Capel minimizes human error and increases productivity. Streamlined workflows enabled by real-time data analytics enable better resource allocation and reduced cycle times.

4.2 Improve quality control:

Capel’s data management system guarantees full traceability and quality control, ensuring customers receive consistently high quality PCBs. Real-time data analysis can identify potential quality issues in the production process, allowing timely corrective actions to be taken.

4.3 Improve flexibility and responsiveness:

Capel’s approach to smart manufacturing is driven by IoT integration, providing unparalleled flexibility. With real-time data, production lines can adapt to changing demands, ensuring responsive workflows. This agility enables Capel to meet varying customer needs while maintaining optimal delivery times.

In conclusion:

Capel’s commitment to smart manufacturing and data management has revolutionized the PCB industry. They integrate robotics, IoT, and real-time data analytics to drive the production of high-quality PCB boards. By reducing errors, increasing efficiency and enhancing quality control, Capel sets new standards in manufacturing. As technology continues to advance, Capel is ensuring its position as a leader in PCB circuit board smart manufacturing and data management.

Post time: Nov-03-2023

Back