Flexible printed circuit boards (PCBs) have revolutionized the world of electronics. They offer unique advantages over traditional rigid PCBs, offering flexibility and saving space, making them ideal for a wide variety of applications. In this blog, Capel will delve into the basics of flexible PCB, including their construction, benefits, and common uses.

The Meaning of Flexible Printed Circuit Board :

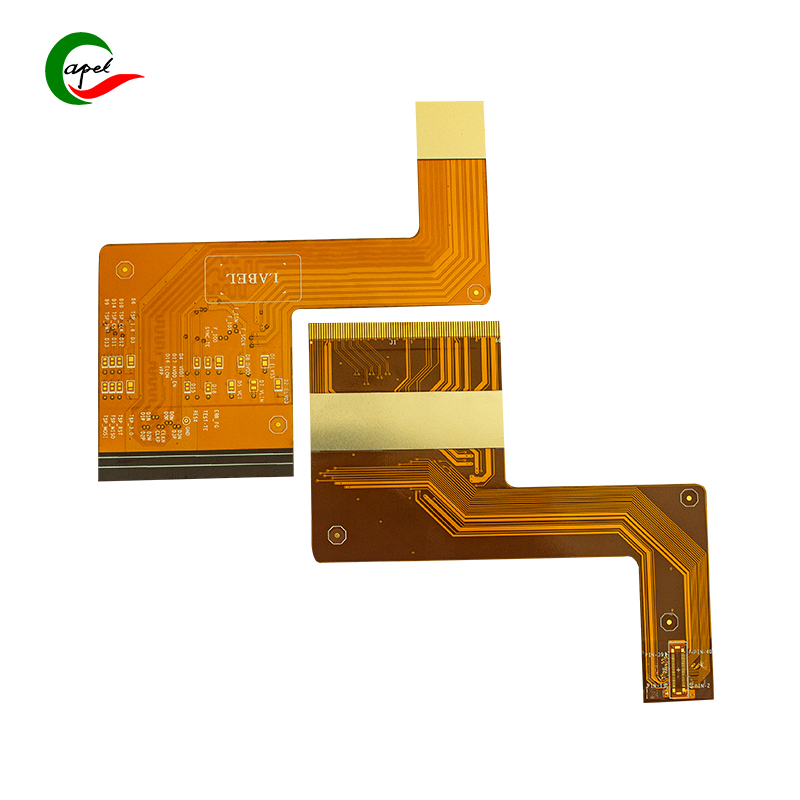

Flexible PCB, also known as flexible circuit or flexible electronic device, is an electronic device that uses a flexible substrate to realize electrical signal interconnection and transmission. These substrates are usually made of flexible polymer materials such as polyimide (PI) or polyester (PET). The flexibility of these materials allows the PCB to bend, twist and conform to its desired shape, making it suitable for a variety of applications.

Flexible Circuit Board Structure:

The construction of a flexible PCB involves multiple layers of material, each layer serving a specific purpose. The base layer (called the substrate) provides overall flexibility. On top of this substrate, a conductive layer is applied, usually made of copper, which acts as an electrical conductor. The pattern of the conductive layer is defined by a process called etching, which removes excess copper and leaves the desired circuitry. Additional layers, such as insulation or cover layers, can be added to protect the circuit and enhance its reliability.

Advantages of Flexible Circuit Boards:

Save Space:

One of the significant advantages of flexible PCBs is the ability to save space in electronic equipment. Compared to traditional rigid PCBs, flexible PCBs can be designed to fit tight spaces, conform to irregular shapes, and even be folded or rolled. This feature is especially useful in modern electronic devices where space is limited, such as smartphones, wearables, and medical implants. The flexibility of flex PCBs also reduces the need for bulky connectors and cables, further optimizing space and reducing complexity.

Lightweight and Flexible:

Flexible PCBs have other advantages as well. Their lightweight properties make them ideal for applications in the aerospace and automotive industries where weight reduction is critical. Flexibility adds durability as they can withstand repeated bending, twisting and vibration without affecting their function. Additionally, flexible PCBs can operate in challenging environments, including high temperatures and harsh chemicals, making them suitable for industrial applications.

Flexible Circuit Board Application Industry:

Today, flexible PCBs are used in various industries. In consumer electronics, they are used in smartphones, tablets and wearables. The medical industry benefits from flexible PCBs in medical implants and diagnostic equipment. The automotive industry incorporates flex printed circuit board into control panels, sensors and lighting systems. The aerospace industry relies on flexible PCBs to implement communication systems, satellite components and flight control systems. These examples demonstrate the adaptability and versatility of flexible PCBs across multiple domains.

FPC Design Considerations:

To ensure the best performance and lifetime of flex PCBs, proper design and manufacturing are critical. Design considerations include routing, material selection, and component placement to avoid unnecessary stress and strain on the flexible substrate. Manufacturing processes such as laser drilling, UV imaging, and controlled impedance play a vital role in producing high-quality flexible PCBs.

The above is how flexible PCB is revolutionizing the electronics industry with its flexibility, space saving and durability. They offer several advantages over traditional rigid PCBs, making them the first choice for many applications. Understanding the basics of fpc PCB from their structure to their benefits and common uses, can provide valuable insight into shaping the future of innovative technology in electronics. Capel has specialized in flexible circuit board manufacturing for 15 years and has accumulated rich project experience. Choose Shenzhen Capel Technology Co., Ltd. to make your project progress smoothly and seize market opportunities.

Post time: Aug-22-2023

Back