When talking about electronic circuit design, two terms often come up: PCB prototyping and PCB manufacturing. Although they look similar, they serve different purposes and have distinct differences. In this blog post, we will explore the differences between these two concepts, their importance in the electronics industry, and how they contribute to the overall development and production of electronic devices. So, let’s dig in and reveal the differences between PCB prototyping boards and PCB manufacturing.

Prototype PCB boards: A glimpse into innovation

Prototype PCB boards, also known as prototype printed circuit boards, play a vital role in the early stages of product development. These boards are precisely engineered as proof-of-concepts, allowing engineers and designers to test their ideas, resolve potential issues, and refine their designs before mass production. Think of a prototype PCB board as the tangible representation of your initial concept for an electronic device.

The main purpose of a PCB prototype board is to verify the functionality and performance of the circuit design. These boards are typically produced in small batches and are highly customizable to accommodate various iterations and modifications. Since speed is critical in the early stages of product development, manufacturing turnaround times for prototype PCB boards are typically fast, allowing engineers to test their designs in a timely manner.

Now let’s focus on PCB manufacturing and how it differs from prototyping PCB boards.

PCB Manufacturing: Turning Concepts into Reality

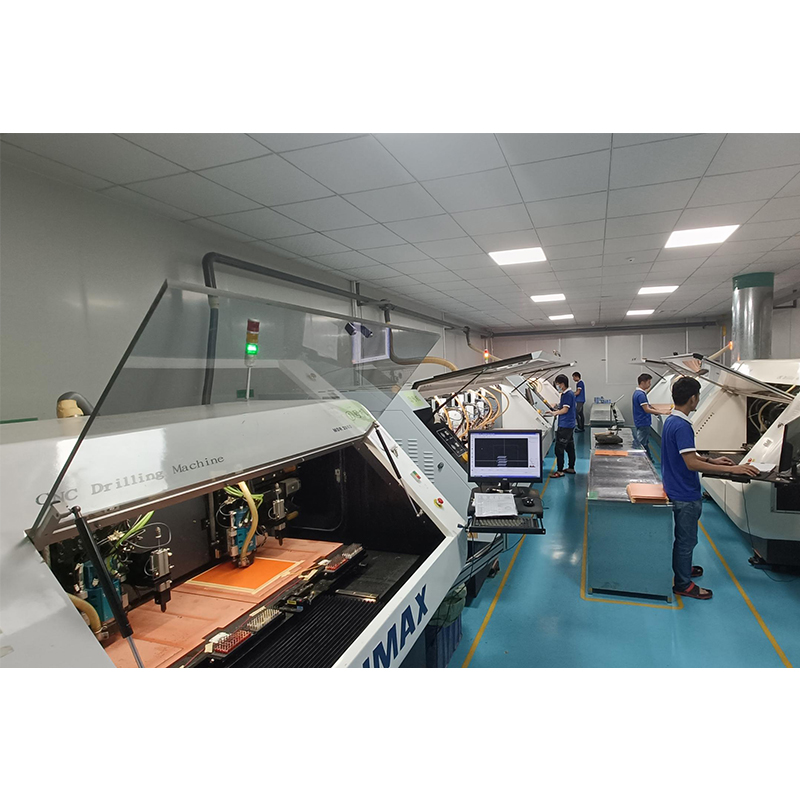

PCB manufacturing, on the other hand, is the process of manufacturing the actual printed circuit boards used in the final product. It involves mass production of PCBs according to specific design specifications and requirements. PCB manufacturing covers various stages including board layout, component placement, soldering and quality control measures to ensure the reliability and functionality of the board.

Unlike prototype PCB boards, which are typically developed in small batches, PCB manufacturing produces large numbers of identical boards. This is because PCB manufacturing is geared toward mass production to meet market demand. As a result, manufacturers optimize their processes to achieve economies of scale, keeping costs low while adhering to high quality standards.

PCB manufacturing prioritizes efficiency, throughput, cost-effectiveness, and repeatability over prototype PCB boards. The goal is to produce reliable, robust PCBs that can be seamlessly integrated into electronic devices during assembly.

Connection Points: Key Differences

Having explored various aspects of prototyping PCB boards and PCB manufacturing, it is time to highlight the key differences between the two concepts.

1. Purpose: The prototype PCB board serves as a proof of concept, allowing engineers to verify and refine their circuit design before mass production. PCB manufacturing, on the other hand, involves manufacturing PCBs on a large scale for use in final products.

2. Quantity: Prototype PCB boards are produced in small quantities, usually just a few, whereas the purpose of PCB manufacturing is to create a large number of identical boards.

3. Customization: Prototype PCB boards provide more flexibility and customization options as engineers continue to iterate and modify their designs. In contrast, PCB manufacturing follows specific design specifications to ensure consistency and repeatability.

4. Turnaround time: Due to the iterative nature of prototype PCB boards, manufacturing turnaround time is relatively fast compared to PCB manufacturing, which requires longer production cycles to meet greater demand.

For anyone involved in the design and production of electronic circuits, it is critical to understand the differences between PCB prototyping and PCB manufacturing. Whether you are an engineer, designer, or manufacturer, recognizing the difference between these two concepts can help optimize product development cycles, improve quality, and reduce time to market.

In summary

PCB prototyping and PCB manufacturing are critical components of electronic circuit design and production. While prototype PCB boards enable engineers to verify and refine their designs, PCB manufacturing ensures mass production of reliable and high-quality printed circuit boards. Each concept fits into a different stage of product development and has its own significance within the electronics industry. So the next time you embark on your electronic circuit design journey, remember the difference between PCB prototyping and PCB fabrication and make the most of each step.

Post time: Oct-13-2023

Back