Introduction:

In this blog post, we’ll take a closer look at flexible PCB lifespan, its factors, and ways to ensure optimal performance throughout its lifecycle.

Flex PCBs, also known as flexible printed circuit boards, have gained popularity in various industries due to their versatility and ability to withstand bending and twisting. These circuits are widely used in electronic devices such as smartphones, wearable technology, medical devices, and automotive applications. However, despite the increasing popularity of flexible PCBs, many people are still unaware of the shelf life of flexible PCBs and their impact on product reliability.

The shelf life of a flexible PCB is the period during which the circuit maintains its expected electrical and mechanical

properties when properly stored. It is affected by a variety of factors, including material composition, manufacturing

processes, storage conditions, environmental factors,assembly and assembly time.

One of the main factors that affects the shelf life of flexible PCBs is material selection. Flexible PCBs are typically made from polyimide or polyester film and offer flexibility and durability. These materials offer good resistance to heat, moisture, and chemicals, allowing circuits to operate in harsh environments. However, over time, these materials can degrade or absorb moisture, causing performance degradation or even circuit failure. Therefore, it is crucial to choose high-quality materials of the right specifications to ensure a longer shelf life.

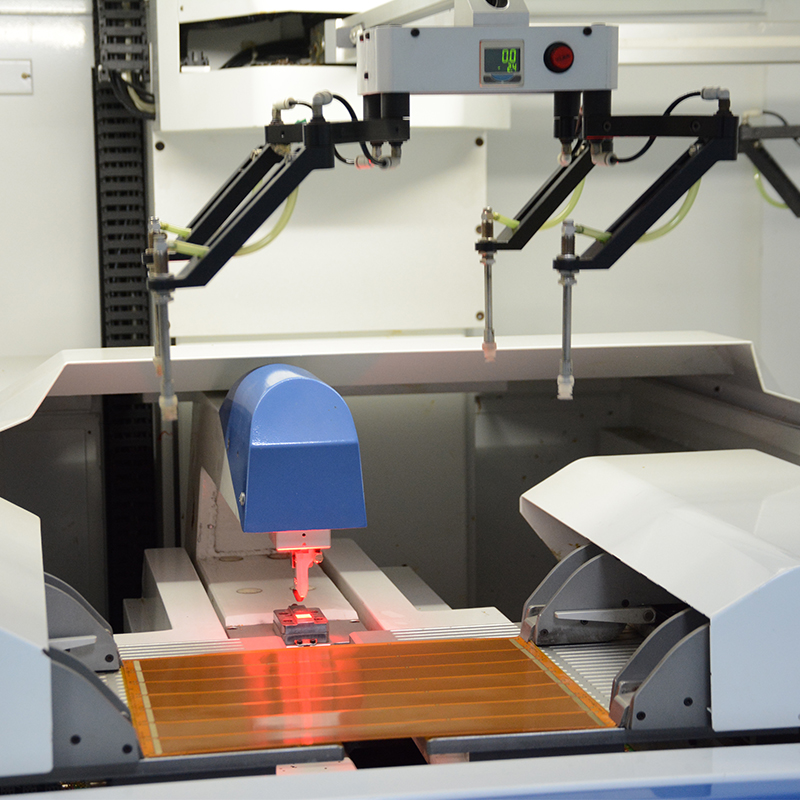

The manufacturing process also plays a vital role in determining the shelf life of flexible PCBs. Proper handling, storage and assembly techniques must be followed to prevent contamination, moisture absorption or damage during production. Any deviation from recommended manufacturing guidelines will compromise the reliability of the circuit and shorten its shelf life. Manufacturers must adhere to industry standards and maintain strict quality control measures to ensure the longevity of flexible PCBs.

Storage conditions significantly affect the shelf life of flexible PCBs. These circuits should be stored in a controlled environment free from excessive humidity, temperature fluctuations, and direct sunlight. Moisture can penetrate the circuit through edges and vias, causing delamination or corrosion of conductive traces. High temperatures accelerate the aging process and reduce material properties. Therefore, it is recommended to store flexible PCBs in sealed polyethylene bags with desiccant packs or in vacuum-sealed containers to minimize moisture absorption.

Environmental factors such as vibration, bending and exposure to chemicals can also affect the shelf life of flexible PCBs. Flexible circuits are designed to withstand repeated bending or twisting, but excessive mechanical stress can cause cracks or breaks in the traces or insulation. Additionally, exposure to corrosive chemicals or gases can degrade circuit materials and impair their performance. Therefore, expected operating conditions must be considered and appropriate protective measures, such as conformal coating or encapsulation, must be taken to enhance the circuit’s durability and extend its shelf life.

To ensure that flexible PCBs perform optimally throughout their shelf life, regular inspection and testing is required. Regular inspections can identify any signs of degradation, such as discoloration, delamination, or changes in electrical performance. Additionally, functional testing can evaluate a circuit’s performance under simulated operating conditions, allowing potential problems to be discovered and corrected before they lead to complete failure. Performing these tests at specified intervals helps extend the shelf life of the flexible PCB and prevent unexpected failures.

To extend the shelf life of flexible PCBs, PCB assembly plays a vital role. PCB assembly refers to the process of mounting electronic components onto a PCB. Proper assembly techniques ensure that components are securely attached to the PCB and that solder joints are reliable.

When it comes to extending the shelf life of PCBs, assembly time after packaging is a critical factor. The PCB should be assembled within a reasonable time after packaging. Long-term storage of packaged PCBs can cause degradation of materials and components, thus affecting shelf life.

The importance of PCB shelf life :

PCB shelf life is important for several reasons. First, using PCBs that are past their shelf life can cause performance issues or failures. Electrical properties such as conductivity and impedance may be affected, causing circuit failure. Mechanical properties, such as flexibility or stiffness, also deteriorate over time.

Second, managing materials and components to extend PCB shelf life is critical to cost effectiveness. By properly managing shelf life, manufacturers can avoid the waste and unnecessary expenses associated with using expired PCBs. This is especially important for industries with higher PCB requirements, as these industries typically stock large quantities of PCBs.

In order to extend the storage life of flexible PCBs, certain precautions should be taken.

First, PCBs should be stored in a controlled environment with appropriate temperature and humidity. Extreme temperatures and humidity can accelerate the degradation of materials and components.

Second, proper packaging is critical to protecting the PCB during storage. They should be packed in moisture-proof and anti-static packaging to prevent any damage or contamination. Additionally, correct marking of production dates and expiration dates is necessary for effective inventory management.

Several factors can affect the shelf life of PCBs.

Exposure to moisture, moisture and corrosive gases can cause accelerated degradation. High temperatures can stress materials and affect their properties. Therefore, it is important to handle and store PCBs carefully to mitigate these factors.

Using expired PCBs can pose significant hazards and risks. Unreliable circuit connections can cause electronic equipment to malfunction, affecting safety and performance. In critical applications such as medical devices or automotive systems, the consequences of using expired PCBs can be severe.

To sum up

The lifespan of flexible PCB is affected by many factors, including material composition, manufacturing process, storage conditions, environmental factors and assembly. By selecting quality materials, following proper manufacturing techniques, storing circuits in a controlled environment and taking into account expected operating conditions, you can extend the shelf life of flexible PCBs and ensure long-term reliable performance. Regular inspections and testing also play a vital role in maintaining circuit integrity and identifying any potential problems. Understanding the shelf life of flexible PCBs is critical for manufacturers, designers and end users to optimize product reliability and longevity.

The shelf life of flexible PCBs is an important consideration for manufacturers and users. Understanding the factors that affect shelf life and implementing correct storage and assembly practices can help extend the life of your PCB. By effectively managing materials and components, manufacturers can ensure optimal performance, cost-effectiveness and safety. Be sure to check with the manufacturer or supplier for specific information about flexible PCB shelf life.

Post time: Oct-11-2023

Back