2 Layer pcb stackup rigid flex pcb manufacturers for Car

How Capel's Rigid-Flex PCBs Provide Reliability Solutions for Automakers

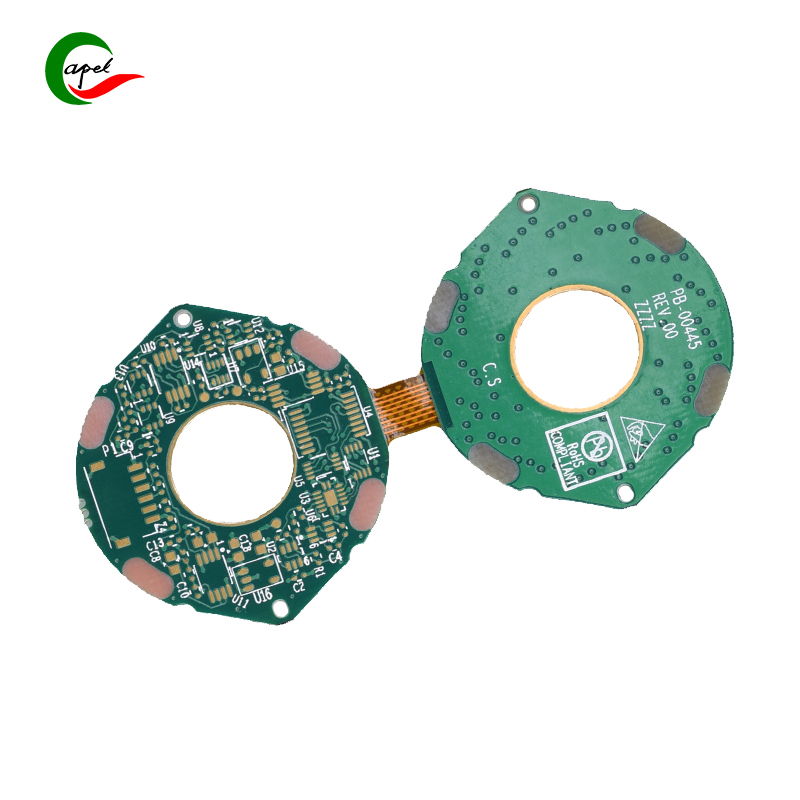

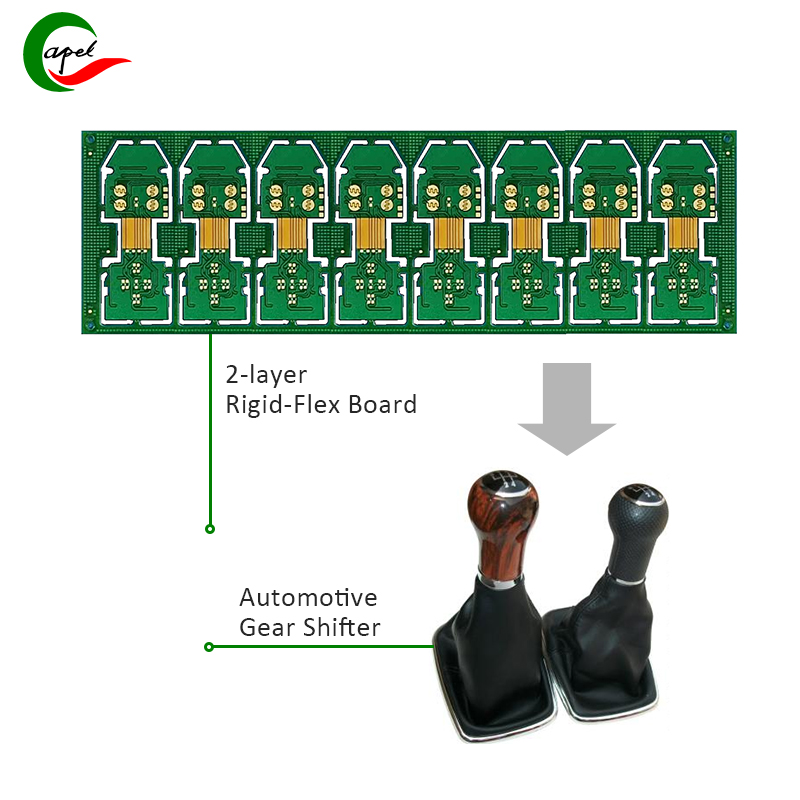

Application Case of 2-layer Rigid-Flex Board in Automotive Gear Shifter

-Capel with 15 years of professional technical experience-

Capel Technology Co., Ltd. is a well-established player in the circuit board industry with 15 years of experience, known for its professionalism, experience, technology, and strength. With a focus on delivering high-quality products and services, Capel has earned high recognition from its automotive partners around the world.

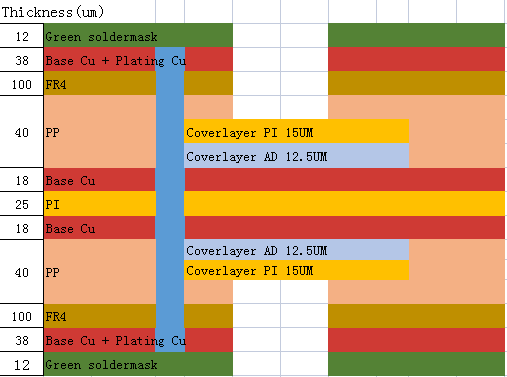

One of the key products offered by Capel is the Rigid Flex Circuit Board. This circuit board is designed with precision and attention to detail, making it a reliable choice for various applications. With a two-layer design and specific line width and spacing of 0.15MM and 0.1MM, respectively, the Rigid Flex Circuit Board ensures optimum performance.

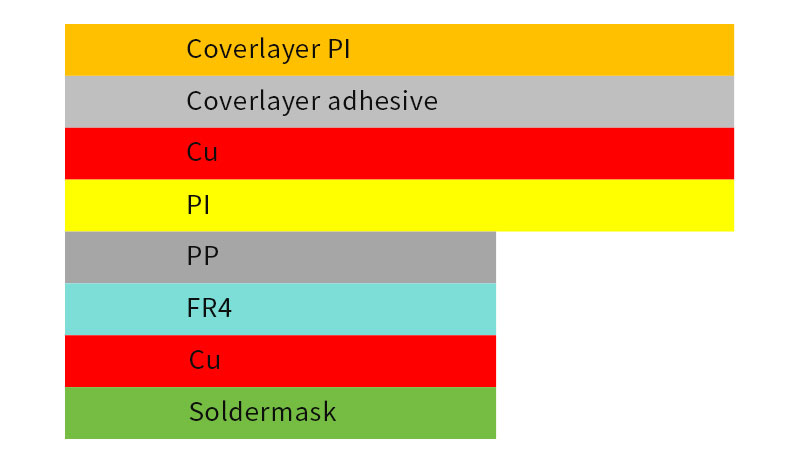

The plate thickness of the Rigid Flex Circuit Board is carefully crafted, with FPC measuring 0.15MM and T being 1.6MM. The copper thickness of 1OZ is perfect for facilitating efficient energy distribution, while the film thickness of 50UM adds durability to the board.

To enhance the longevity and performance of the Rigid Flex Circuit Board, Capel incorporates ENG 2-3U surface treatment. This surface treatment ensures high adhesion, which in turn leads to high reliability. Additionally, the Rigid Flex Circuit Board undergoes various functional testing, including AOI, four-wire, continuity, and copper slices inspection, guaranteeing flawless operation.

One of the main applications of the Rigid Flex Circuit Board is in vehicle cars made in Japan. These vehicles require durable and reliable components to ensure smooth and safe operation. With Capel's Rigid Flex Circuit Board, car manufacturers can trust in the quality and performance of their gear shift knob. The Rigid Flex Circuit Board offers high tolerance requirements of 0.1MM, ensuring precise and accurate operation.

Capel sources its materials from trusted suppliers, and the Rigid Flex Circuit Board is made using Shengyi TG170 Copper-clad laminate. This material is well-known for its high quality and durability, further contributing to the reliability of the board.

Capel Technology Co., Ltd. has gained significant recognition in the circuit board industry, thanks to its professionalism, experience, technology, and strength. The Rigid Flex Circuit Board offered by Capel demonstrates these qualities, with its carefully designed specifications, high tolerance requirements, and functional testing. For car manufacturers looking for a reliable partner in the circuit board industry, Capel is the perfect choice. Trust Capel to deliver high-quality Rigid Flex Circuit Boards that meet your specific requirements and enhance the performance of your vehicles.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

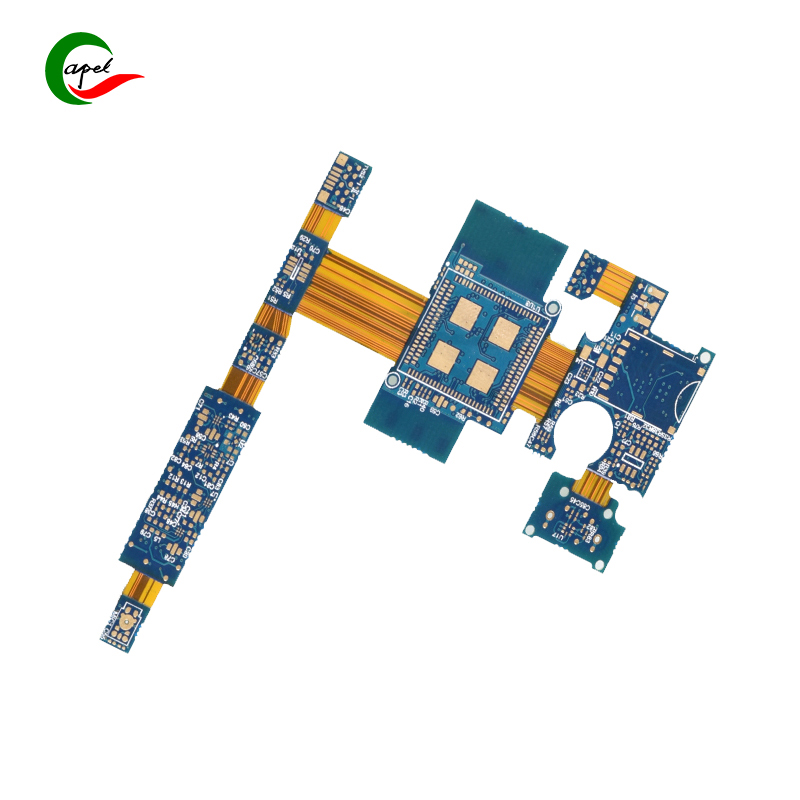

Capel do customize Rigid Flex PCB with 15 years of experience with our professionalism

2 layers Flexible Rigid PCB

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.Provide 24-hour PCB Prototyping 24 hours PCB prototyping service ; Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.