6 layer Hdi Flex Pcb Steel sheet FR4 Multilayer Pcb Manufacturing Quick Turn Prototype

How Capel's Multilayer HDI Flex Pcb Board Provides Reliability Solutions for Industry Control

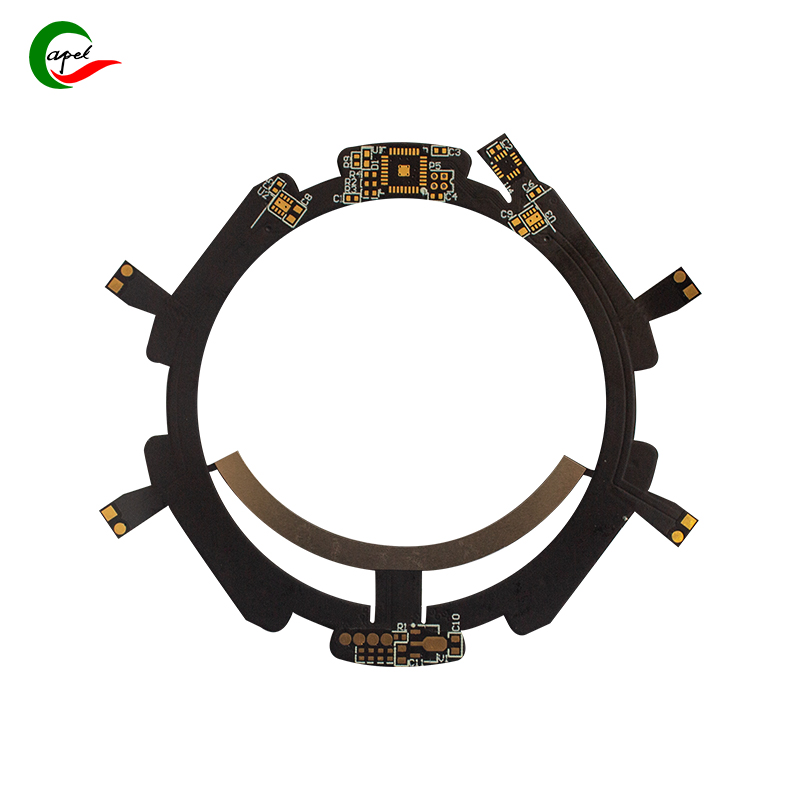

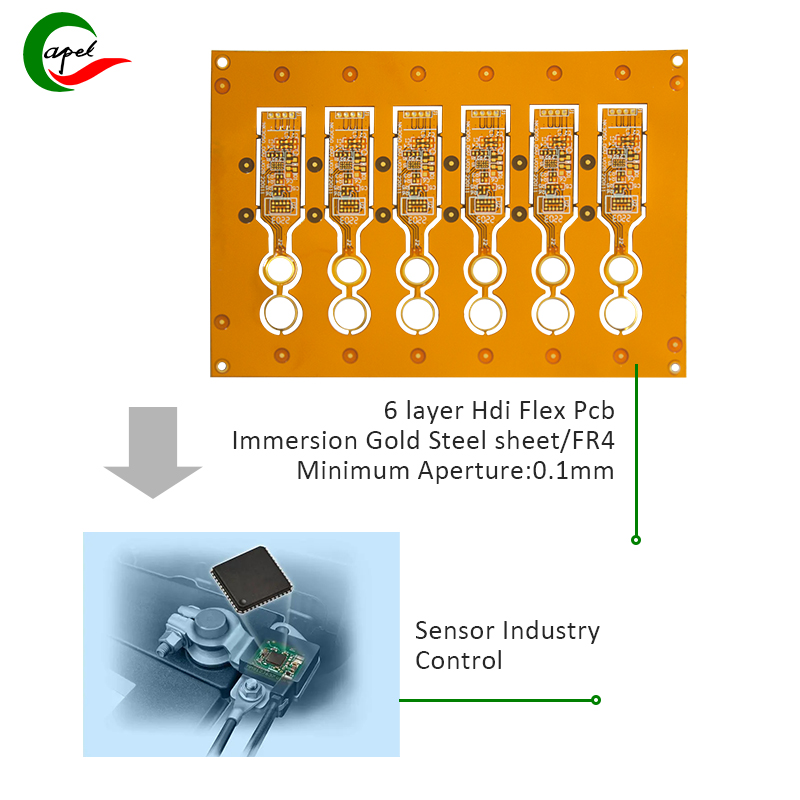

6 layer Hdi Flex Pcb with Steel sheet/FR4 applicated in Sensor Industry Control

-Capel with 15 years of professional technical experience-

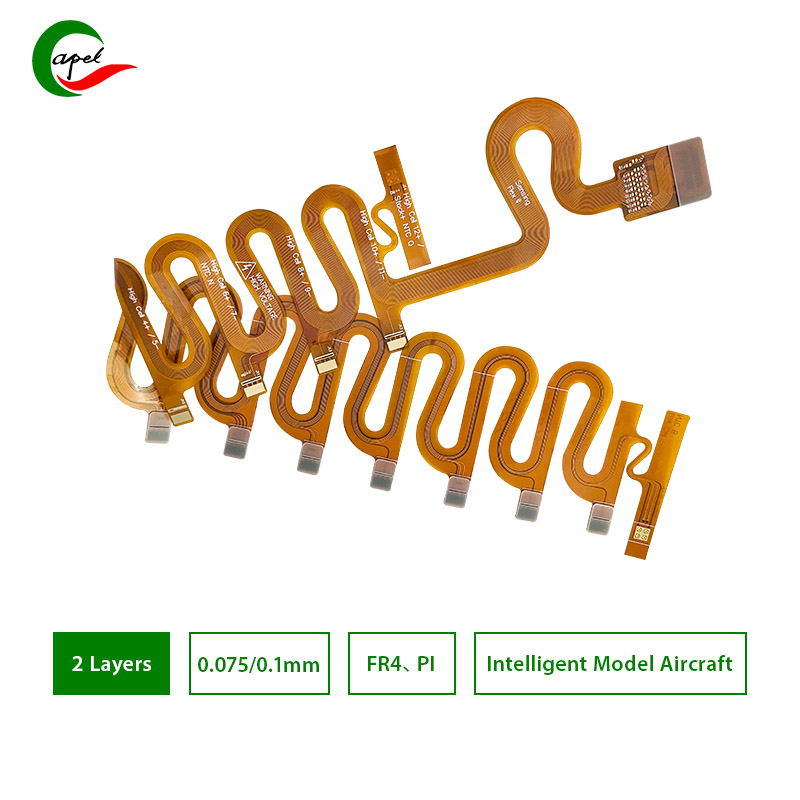

Introducing our latest innovation in the field of printed circuit boards - 6-layer HDI Flex PCB. Designed to meet the changing needs of the industry, this cutting-edge technology is revolutionizing the way sensors are used in industrial control applications.

Our company prides itself on providing exceptional services covering PCB fabrication, fabrication and assembly. Our expertise lies in HDI PCB prototypes and quick-turn rigid-flex PCBs, ensuring timely delivery without compromising quality. Our turnkey PCB assembly solutions seamlessly integrate all aspects of the manufacturing process, further simplifying your production cycle.

When it comes to the technical specifications of our 6-layer HDI Flex PCBs, we are confident in delivering best-in-class performance. The PCB has a line width and line spacing of 0.05/0.05mm for unrivaled precision and reliability. The board thickness is 0.2 mm, providing flexibility while maintaining structural integrity. 12um copper thickness ensures efficient transmission of electrical signals.

A minimum hole diameter of 0.1mm allows the installation of smaller components, enabling complex designs and maximizing space utilization. Our 6-layer HDI Flex PCBs are also equipped with 94V0 flame retardant for safety and compliance with industry regulations. The immersion gold finish increases the reliability and longevity of the PCB, while the resistance-soldered yellow color adds to the aesthetic.

The rigidity of the 6-layer HDI Flex PCB is achieved by integrating steel plates and FR4, providing durability without compromising flexibility. This unique combination can be seamlessly integrated into various industrial control applications, especially in the sensor industry. Whether it is a motion sensor, proximity sensor, temperature sensor or any other type of sensor, our 6-layer HDI Flex PCB is the ideal solution.

With its superior performance, our 6-layer HDI Flex PCB excels in precision, accuracy and stability. Its advanced technology ensures the transmission of real-time data, enabling seamless communication between sensors and control systems. This allows precise monitoring, control and analysis, improving industrial operations' overall efficiency and productivity.

In addition to technical excellence, our 6-layer HDI Flex PCBs are designed with ease of use and convenience in mind. Its compact size and lightweight construction make it easy to adapt to various applications, further optimizing your system design. Coupled with our efficient customer support and after-sales service, we strive to provide a seamless experience from idea to implementation.

We understand the importance of maintaining a leading position in today's dynamic market, and innovation is the key to success. With our 6-layer HDI Flex PCBs, you can have confidence in the reliability and performance of your industrial control systems. Experience a new level of sensor integration with our state-of-the-art PCB technology.

So, whether you are in the field of industrial controls or involved in sensor manufacturing, our 6-layer HDI Flex PCB is the ultimate choice. Trust us to provide top-notch PCB fabrication, fabrication and assembly services. Stay one step ahead of the competition with our revolutionary solutions. Contact us today to discuss your needs and collaborate with us to create a seamless and efficient industrial control system.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

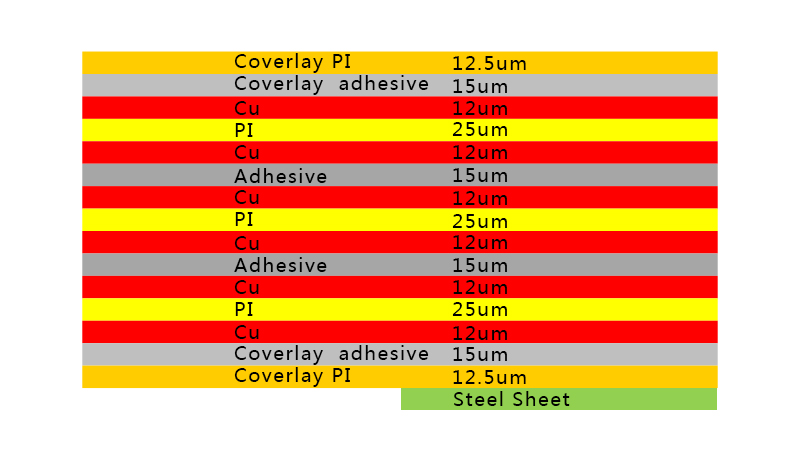

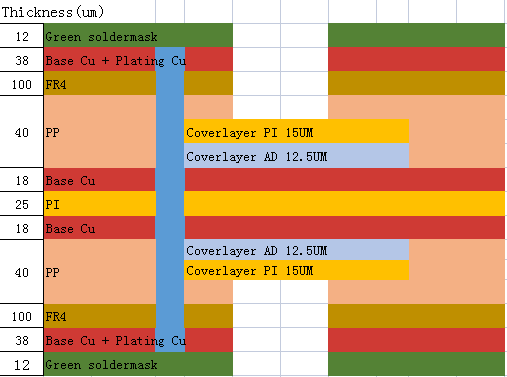

6 layer Hdi Flex Pcb Board Stackup

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.