Learn about Capel’s unparalleled expertise in 10-layer FPC-rigid flexible pcb solutions tailored for military spacecraft applications. Delve into the precision, technology and process capabilities that set Capel apart in the aerospace and defense industry

Mastering precision: Capel’s 10-layer FPC with rigid-flex technology for military spacecraft

In the intricate network of technologies, the need for agile, robust and precise solutions in the aerospace and defense industry has become particularly evident. Capel has pioneered innovation and carved a niche for itself in the field of 10-layer rigid-flex PCBs tailored for military spacecraft applications. With 16 years of expertise in the field, Capel’s proficiency in flexible circuit board design, prototyping and manufacturing is a testament to its unwavering commitment to precision, reliability and technical superiority.

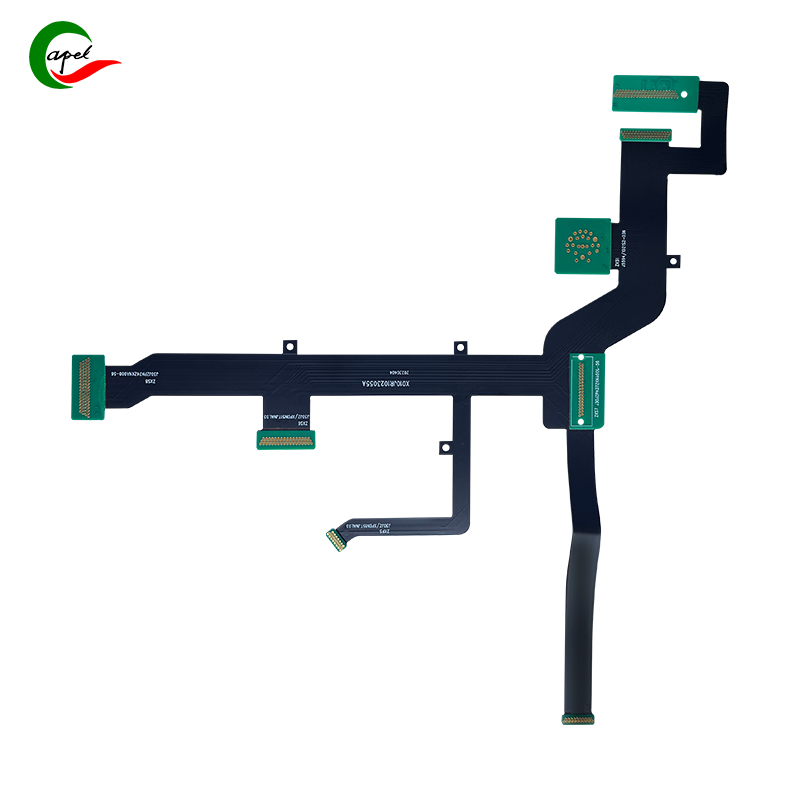

Setting the Standard for 10 layer FPC with rigid-flex pcb technology: Product Overview

Capel’s 10-layer rigid flex PCB solution is designed to exceed the stringent requirements of military spacecraft applications. Its outstanding features include 2.0MM+-10% board thickness, carefully crafted 4+2+4 layer stacking, and 0.1mm/0.1mm line width and line spacing. In addition, the minimum hole diameter of the PCB is 0.2mm, the copper hole thickness is 35um, the surface treatment is ENIG 2-3uin, and the impedance is as high as 50 ohms – +10%.

Demonstrating technical mastery in 10 layer FPC with rigid flexible circuit board technology: Capel’s proven craftsmanship

Driven by an unwavering commitment to excellence, Capel continues to raise the bar by combining cutting-edge technology with strong craftsmanship capabilities. The complexity of the 10-layer rigid flex PCB requires precision in every aspect of its conception and manufacturing, and Capel has mastered this art through its diverse product portfolio and 16 years of hands-on experience.

The 10-layer rigid-flex PCB thrives at the core of Capel’s technological prowess and is a testament to its advanced manufacturing capabilities. From meticulous execution of specified line widths and spacing, to layer stacking envisioned to maintain the integrity of military spacecraft applications, Capel’s skilled team goes above and beyond to deliver products that exceed industry standards.

Unwavering Commitment to Accuracy in 10 layer FPC with rigid flexible Technology: Tolerance Accuracy and Warpage

In complex technical fields, the devil is in the details, and Capel deftly navigates these intricate nuances with his relentless pursuit of precision. With a tolerance accuracy of ±0.1MM, Capel ensures that every component of the 10-layer rigid-flex PCB adheres to the tiniest specifications, positioning itself as an unparalleled industry player.

Additionally, warpage is a key determinant of PCB efficacy and is carefully controlled to ≤0.5%. This unwavering commitment to keeping warpage to a minimum is a testament to Capel’s unwavering pursuit of delivering products that go above and beyond and stand the test of time in military spacecraft applications in the aerospace and defense sectors.

The mysterious brilliance of surface treatment of 10 layer FPC with rigid-flex technology: ENIG 2-3uin

An important aspect of a 10-layer rigid-flex PCB solution is surface treatment, and Capel’s choice of ENIG 2-3uin symbolizes its relentless pursuit of excellence. Electroless Nickel Immersion Gold (ENIG) treatment ensures impeccable solderability, oxidation resistance and pristine surface properties, further enhancing PCB reliability and durability in the rigorous environmental characteristics of military spacecraft applications.

Seamless integration of advanced technologies in 10 layer FPC with rigid-flex technology: impedance capabilities

The impedance of a PCB is closely related to its operability, and Capel’s 10-layer rigid-flex PCB solution has an impedance of up to 50 ohms +10%. This extraordinary feat highlights Capel’s unparalleled expertise in PCB engineering and manufacturing and marks its ability to seamlessly combine advanced technology with precision to meet the stringent requirements of military spacecraft applications.

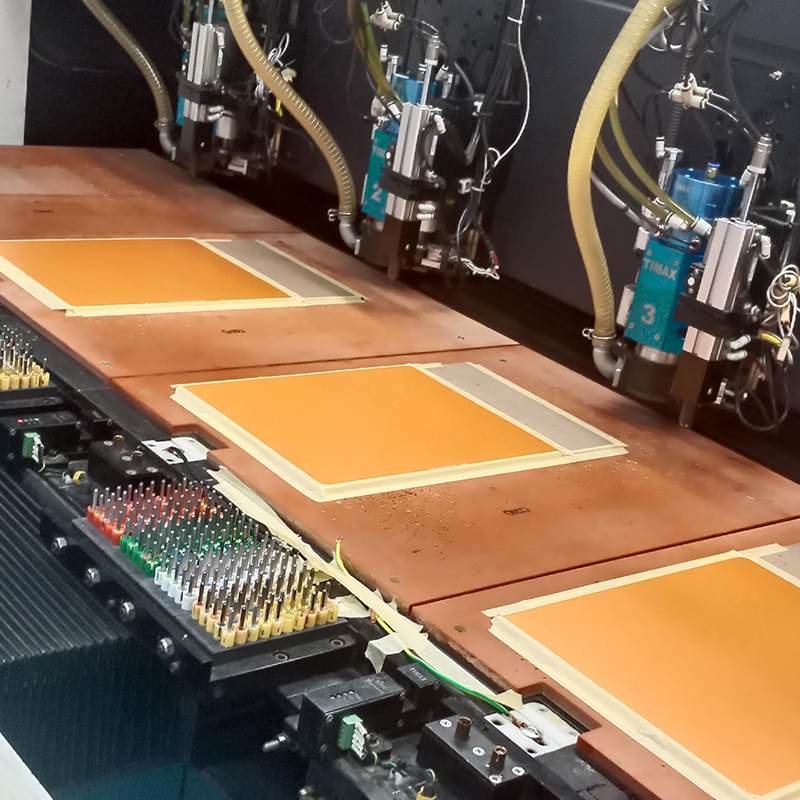

10 Layer FPC With Rigid-Flex Technology Prototyping and Fabrication Solution

Conclusion: Consolidating the future

In an evolving technology landscape, the critical role that 10-layer FPC-rigid-flex PCBs play in military spacecraft applications cannot be overstated. As the industry grapples with constant technological change, Capel is a relentless force, cultivating a future where precision, reliability and innovation combine to redefine the benchmark for excellence.

For 16 years, Capel has been firmly pursuing the pinnacle of technology, and its 10-layer rigid-flex PCB solution tailored for military spacecraft applications reflects its unremitting commitment to excellence. From precision to reliability, from advanced technology to unwavering process capabilities, Capel has been a pioneer in innovation, solidifying the future of aerospace technology with its indelible excellence in craftsmanship and unparalleled expertise.

In a booming aerospace and defense industry where precision is key and technological resiliency is a priority, Capel not only remains, but becomes a pioneer in a new era in which military spacecraft applications are not only met, but surpassed with determination. Shift is committed to excellence.

Post time: Mar-05-2024

Back