15 Years PCB Board Manufacturer: Your Partner for Quality and Innovation

Introduce:

For the past 15 years, our company has been a leading PCB manufacturer dedicated to providing high quality and innovative solutions to our esteemed customers. We have earned a solid reputation for our extensive industry experience, skilled R&D team, cutting-edge technology, and commitment to exceptional customer service. In this blog, we’ll take an in-depth look at our PCB manufacturing capabilities, our stringent quality control measures, and the range of services we offer to meet your specific requirements.

Circuit Board Type and PCB Experience:

As a leading Pcb Manufacturing manufacturer driving the development of the industry, we specialize in the production of various types of PCBs, including flexible PCB (FPC), rigid-flex, multi-layer PCB, single/double-sided circuit board, hollow board, HDI board, Rogers PCB , RF PCB, metal core PCB, special process board, ceramic PCB, DIP SMT assembly and PCB prototype service. Our proven technology enables us to manufacture flexible circuit boards from 1 to 30 layers, rigid-flex circuit boards from 2 to 32 layers, and rigid PCBs from 1 to 60 layers. Whether you need single-sided PCB, double-sided PCB, multi-layer PCB, rigid-flex circuit board or flexible circuit board, our mature professional technology and state-of-the-art automation equipment can meet your needs. 15 years of experience, serving more than 100 industries and more than 200,000 successful cases. The industries we serve include medical devices, Internet of Things, TUT, drones, aviation, automobiles, telecommunications, consumer electronics, military, aerospace, industrial control, artificial intelligence, electric vehicles, etc. We understand the unique requirements and regulatory standards associated with each industry, ensuring our PCBs meet the highest standards of quality and reliability.

R & D Team and Technology:

Our success is attributed to our strong team of 1,500 experts, including an experienced R&D team with 15 years of industry experience, who have solved countless challenging and complex cases. With expertise in PCB design, layout and manufacturing processes, they work tirelessly to develop new optimized solutions for our customers. We continually invest in state-of-the-art technology to maintain our industry leadership, allowing us to take advantage of the latest advances in PCB manufacturing technology to improve product performance and reduce production time.

Industry Engagement and Certification:

We actively participate in industry events and associations to stay abreast of the latest trends and technological advancements. This involvement ensures that our PCB manufacturing processes remain current and in line with industry standards. We adhere to strict quality control measures and abide by the quality management system throughout the production and testing process. In addition, we have obtained ISO 14001:2015, ISO 9001:2015, IATF16949:2016 and other international certifications. Our products are also certified by UL and ROHS. Through strict quality inspection, we ensure that the defect rate of PCB products is less than 1%, guaranteeing that every product delivered to customers meets their requirements. We are committed to continuous improvement and innovation.

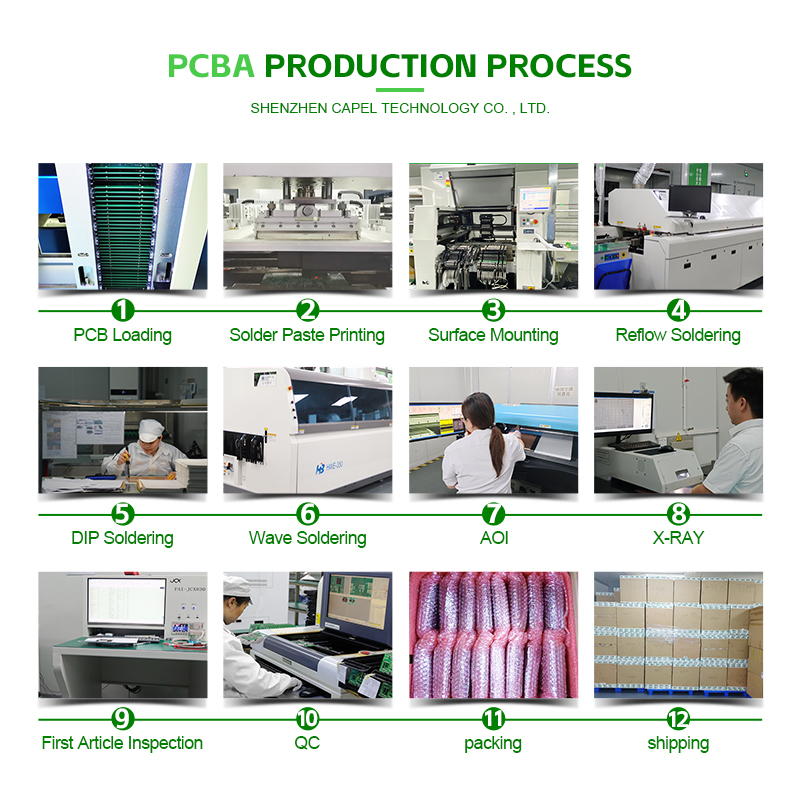

PCB Production Capacity and PCB Process:

Our production facilities are well-equipped with advanced automation. We have three well-defined factories specializing in flex and rigid-flex circuit board manufacturing, rigid circuit board manufacturing, and DIP/SMT assembly. This advantage enables us to meet diverse production requirements. Our production capabilities are equipped with high-precision machinery for PCB fabrication, assembly and testing. We meticulously follow a streamlined production process, including design verification, material selection, production planning, circuit fabrication, component assembly, and final testing. Each step is carefully monitored to ensure consistency, accuracy and compliance with client specifications.

Quality Control and Customer Satisfaction:

We are well aware of the importance of a perfect PCB to maintain the normal operation of electronic equipment. Our robust quality control measures include manual inspections and automated tests, such as incoming quality control (IQC), in-process quality control (IPQC)/FAl testing, post-reflow visual inspection/AOI, pre-reflow visual inspection, QA random Inspection, Outgoing Quality Control (OQC), High Tech PCB Assembly Services (SMT/DIP Wire), Professional Component Sourcing, Innovative Programming and Functional Testing to ensure the highest level of product integrity. From the initial design to the final product, each stage is strictly tested to find and solve any abnormal situation in time.

Our commitment to quality is not limited to manufacturing, we also provide timely pre-sales and after-sales services, and have more than 200 technical professionals online to answer any doubts or inquiries from customers.

Understand customer support needs:

In the fast-paced world of PCB manufacturing, having reliable and accessible customer support is essential. We understand the complexities and challenges of the process, and our dedicated team is ready to resolve any issues and provide proactive assistance.

Timely response, smooth experience:

At our company, we value your time and prioritize prompt responses. Through efficient communication channels, our customer support team ensures that your queries and requests are resolved urgently. By reducing wait times and keeping you fully informed, our goal is to enhance your overall experience.

Communicate transparently to build trust:

Transparency plays a vital role in fostering trust between us and our clients. We believe in keeping you informed about the progress of your PCB fabrication project, any potential delays, and estimated delivery timelines. This two-way communication creates a solid foundation for a long-term partnership.

Personalized assistance for customized needs:

Every customer has unique requirements for their PCB boards. To meet these specific needs, our support team provides personalized assistance. From choosing the right material to designing the PCB layout, we work with you to ensure the best possible results.

Troubleshooting and expert guidance:

Manufacturing sometimes runs into unexpected problems. Our experienced customer support team conducts thorough troubleshooting to identify and resolve any issues that may arise. With their expertise, they provide invaluable guidance to keep your project on track.

Ongoing support for faster time to market:

We understand the importance of meeting deadlines in a competitive industry. Our customer support team is dedicated to helping you speed up your time to market. By providing ongoing support and quickly addressing any roadblocks, we ensure your product is on time to market.

Patent and Quick turn PCB Prototyping:

Innovation is at the heart of our PCB manufacturing process. Over the past 15 years, we have continued to invest in research and development, and have obtained dozens of patented technologies, covering flexible circuit boards, rigid circuit boards, rigid-flex boards, HID boards, etc., which has consolidated our position as an industry pioneer.

Additionally, we offer PCB prototyping services through our reliable and fast PCB prototyping department. From design to testing to shipment, we meticulously control quality, enabling our customers to validate their designs before final production. This allows for potential modifications and optimizations, ultimately creating a superior end product.We understand the importance of fast, reliable PCB prototyping. We professionally provide 24-hour PCB proofing service to ensure that small batches of circuit boards will be delivered within 5-7 days. We also offer mass production of PCB boards, which can be delivered within 2-3 weeks, depending on the complexity of your requirements.

Full PCB Assembly Services: We go beyond PCB prototyping to provide full assembly services. Our team is capable of handling complex assembly requirements, ensuring your boards are fully functional and ready to use. With our end-to-end solutions, you can save time and streamline your production process.

In summary

As a 15 Years PCB Board Manufacturer, we have earned a reputation for excellence based on deep industry knowledge, cutting-edge technology and commitment to customer satisfaction. From PCB prototyping to mass production, our services cover every step of the PCB manufacturing process. Our stringent quality control measures, certifications and dedication to innovation ensure our customers receive unrivaled PCB quality and reliability. Partner with us today and experience the difference our expertise and capabilities can make for your electronics projects.Contact us today to discuss your project in the shortest possible time.

Post time: Aug-17-2023

Back