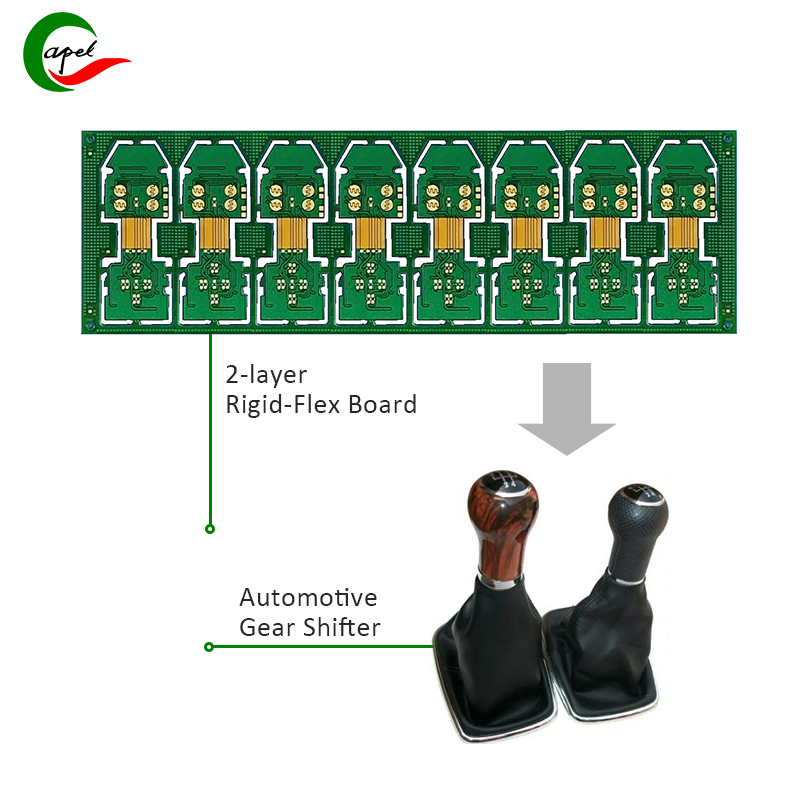

What is 2 Layer Rigid-Flex PCB?

To understand the true potential of a 2-layer rigid-flex PCB, one must grasp its basic structure and composition. Manufactured by combining rigid circuit layers with flexible circuit layers, these PCBs offer a unique solution for complex electronic designs. The addition of rigid and flexible components increases durability, reliability and adaptability.

The rigid portion of the PCB provides robustness and stability, making it ideal for housing components that require fixed positions. On the other hand, the flexible part allows bending and folding, making it suitable for applications involving tight spaces or constant movement. By seamlessly integrating rigid and flexible components, designers can develop complex electronic devices that are both lightweight and compact.

What is Automotive Shift Kno?

The gear shift knob, also known as the gear lever or shifter, is the handle that the driver uses to engage the different gears in a manual transmission vehicle. It’s usually located on the center console of the car, within easy reach of the driver’s hand. While it might seem like an inconspicuous little part of your car, choosing the right shift knob can greatly enhance your driving experience.

How 2 Layer Rigid-Flex PCB Provides Solution for Automotive Gear Shift Knob?

Capel’s 2-layer rigid-flex PCB Applicated to Car Gear Shift Knob

If you’re looking for a reliable and high-quality solution for your car gear shift knob, look no further than Capel’s 2-layer rigid-flex PCB. This advanced and innovative technology is revolutionizing the automotive industry, providing improved performance and durability.

Our rigid-flex PCB is specifically designed for use in car gear shift knobs, ensuring a smooth and seamless experience every time you drive. With its high adhesion and reliability, you can trust that our PCB will withstand the harshest of conditions and continue to perform at its best.

Superior Performance and Flexibility:

In addition to superior performance, our rigid-flex PCB has several other advantages that make it ideal for automotive gear shift knobs. First, its flexibility allows it to conform to the unique shape of the shift knob housing, maximizing space utilization and minimizing weight. This flexibility also makes installation easier and reduces the risk of damage during assembly.

Optimize Signal Integrity and Reduce Electromagnetic Interference (EMI):

Additionally, our rigid-flex PCBs are designed to optimize signal integrity and reduce electromagnetic interference (EMI). This ensures reliable communication between the shift knob and vehicle control systems, resulting in smooth, precise gear changes.

High-Density Routing Capabilities:

Additionally, the high-density routing capabilities of our Circuit boards allow the integration of various sensors and switches to enhance the functionality of the shift knob. Moreover, our circuits pcb are manufactured using advanced technology and strict quality control process. From prototype to production, our experienced team ensures that each PCB meets the highest quality and performance standards. This attention to detail ensures that our rigid-flex PCB for automotive shift knobs will perform flawlessly for years to come.

High Adhesion Properties:

One of the standout features of our PCB board is its high adhesion properties. This allows for seamless integration into the gear shift knob, ensuring that it stays securely in place even during intense driving conditions. You don’t have to worry about the PCB coming loose or causing any disruptions to your driving experience. With Capel’s 2-layer rigid-flex PCB, you can drive with confidence and peace of mind.

Excellent Durability:

In addition to the high adhesion properties, our 2-layer rigid-flex PCB has several other advantages that enhance the driving experience. First, the high-quality material of our printed circuit board ensures excellent durability. It is designed to withstand the extremes of temperature, vibration and mechanical stress common in automotive applications. This means that even during intense driving or off-road adventures, the PCB will continue to perform optimally, giving you reliable and uninterrupted shifting.

Advanced Protection Features:

In addition, our printed circuits are equipped with advanced protection features. It has built-in protection against overvoltage, overcurrent, and electrostatic discharge (ESD). These protections ensure the longevity of the PCB and connected components, preventing any potential damage or failure that could affect your driving experience.

Integration :

Additionally, our 2-layer rigid-flex PCB is engineered to optimize space utilization within the shift knob. It is compact and lightweight, enabling design flexibility and easy integration with other electronic components. This ensures that the shift knob maintains its sleek and ergonomic design without compromising functionality or performance.

Finally, our flexible rigid boards go through a rigorous testing and quality control process to meet industry standards and exceed customer expectations. We are committed to high quality products, and you can trust our 2-layer rigid-flex PCB will consistently perform at its best, giving you a seamless, reliable shifting experience.

High Reliability:

In addition to its high adhesion, our PCB is also known for its high reliability. We understand the importance of having a gear shift knob that performs consistently and doesn’t fail unexpectedly. That’s why our rigid-flex PCB undergoes rigorous testing to ensure its reliability. From functional testing to tolerance requirements, we leave no stone unturned in guaranteeing the quality of our product.

To ensure the high reliability of rigid-flex boards, we implement a comprehensive testing and quality assurance process. The process begins with functional testing, where each PCB undergoes extensive performance evaluation to ensure it performs as intended. This includes testing its electrical connectivity, signal integrity, and compatibility with other components.In addition to functional testing, our rigid-flex boards undergo rigorous environmental testing. This involves exposing them to various conditions such as extreme temperatures, humidity, vibration and mechanical stress. By simulating real-world operating conditions, we can verify that our PCB can withstand the harsh environment faced by a shift knob.

Perform at a High Level:

Additionally, our quality assurance process includes strict tolerance requirements. We use advanced manufacturing techniques and adhere to industry standards to ensure our rigid-flex circuit boards meet precise specifications. This level of precision ensures that our pcb boards consistently perform at a high level and do not deviate from their intended function. To further increase reliability, we also employ robust design practices. Our engineers carefully design the PCB layout, paying close attention to factors such as component placement, signal routing, and thermal management. These design considerations help to increase the overall reliability and service life of our products.

Meet the Strictest Quality Standards:

Speaking of testing, our PCB goes through various processes to meet the strictest quality standards. Each PCB is subjected to AOI (Automated Optical Inspection), four-wire testing, continuity testing, and copper slice testing. These tests ensure that our PCB is fully functional and meets all the necessary specifications. With Capel’s 2-layer rigid-flex PCB, you can expect nothing but the best performance and reliability.

AOI (Automated Optical Inspection) process uses advanced imaging techniques to inspect PCB’s for any defects or inconsistencies in soldering, component placement and overall solder joints. This automated approach to inspections allows us to quickly and accurately identify potential issues, saving time and effort.

Four-wire testing is another critical step in our quality control process. This test method verifies the accuracy and integrity of the electrical connections on the PCB. By measuring the resistance value and comparing it to predetermined specifications, we can identify any potential problems with the circuit. This helps us ensure that the PCB will perform reliably under a wide range of operating conditions.

Continuity testing is equally important to ensure proper functionality of a 2-layer rigid-flex PCB. This test checks for opens or shorts that could affect the overall performance of the PCB. By applying a current and measuring the response across the board, we can quickly identify any irregularities that may need to be corrected before the PCB can be approved for use.

Additionally, we perform copper strip testing to verify that the copper traces on the PCB are free of any defects or discontinuities. This testing process helps us ensure that the electrical connections on the board are strong and reliable, ensuring optimum performance and longevity of your shift knob.

By subjecting our 2 Layer Rigid-Flex boards to these rigorous testing procedures, we can confidently say that our products meet the highest quality standards. We strive to provide PCBs that not only function flawlessly, but also exhibit outstanding durability and reliability. With Capel’s 2-layer rigid-flex PCB, you can be confident in the performance and longevity of your shift knob.

The technical Specifications Of Our Rigid-Flex PCB:

Now let’s talk about the technical specifications of our rigid-flex PCB. It is a 2 layer circuit board with a line width and line spacing of 0.15mm/0.1mm. The plate thickness consists of a 0.15mm FPC (Flexible Printed Circuit) and a 1.6mm T (Thickness) layer. The copper thickness is 1OZ, providing excellent conductivity and signal transmission. The film thickness is 50UM, ensuring optimal flexibility without compromising on durability. The surface treatment is ENIG 2-3uin, further enhancing the PCB’s adhesion properties. With a tolerance requirement of 0.1mm, our PCB meets the highest precision standards.

In addition to the technical specifications above, our rigid-flex boards undergo a thorough testing and inspection process to ensure performance and meet quality standards.

Evaluate The Electrical Performance:

To evaluate the electrical performance of a PCB, we conduct electrical tests. This involves applying various voltage and current levels to the circuit and measuring the response to ensure that electrical signals flow correctly without any interruptions or deviations. This test helps us to verify that the PCB meets the required specifications and can transmit signals reliably.

Evaluate The Mechanical Durability And Flexibility:

In order to evaluate the mechanical durability and flexibility of the PCB, bend and bend tests were performed. These tests simulate real-world usage conditions and evaluate how a PCB will withstand repeated bending and bending cycles. By performing these tests on a rigid-flex PCB, we ensure that it maintains its structural integrity and functionality even under dynamic conditions.

Environmental Performance:

In terms of environmental performance, our rigid-flex boards have undergone environmental tests. This involves exposing the PCB to various environmental factors such as temperature, humidity and vibration to assess its ability to withstand harsh operating conditions. This testing helps us ensure that the PCB will perform reliably and consistently in different environments.

Highest Level Of Precision And Accuracy:

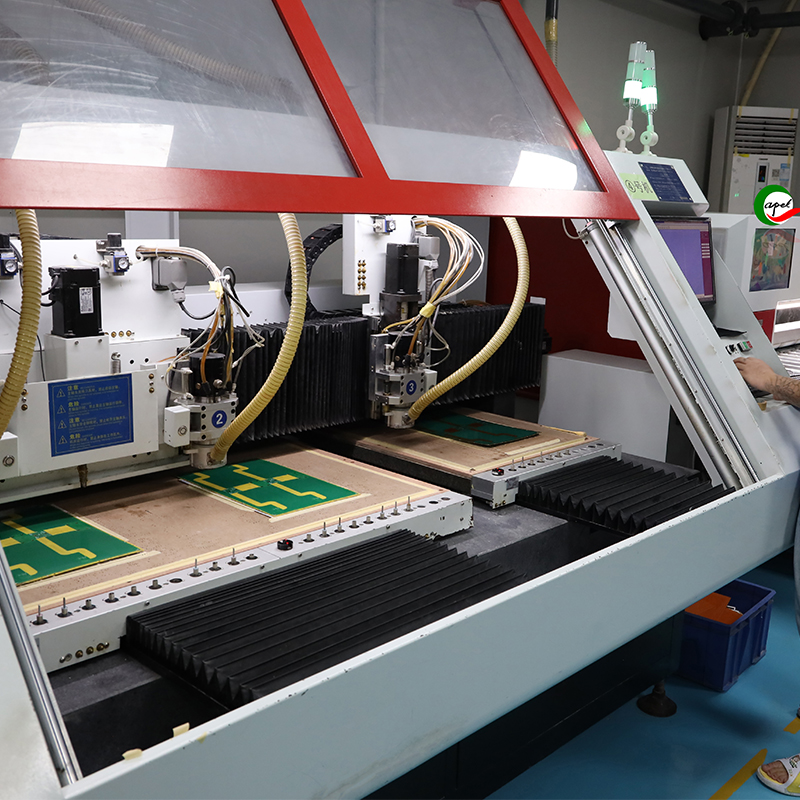

Additionally, we employ a comprehensive quality control system throughout the manufacturing process to monitor and address any potential defects or deviations. This ensures that our rigid-flex PCBs are produced with the highest level of precision and accuracy, meeting the strictest industry standards.

By combining these testing and quality control measures, we can confidently say that our rigid-flex boards provide superior functionality, durability and reliability. Whether it’s automotive, aerospace or any other industry, our PCBs are engineered to provide superior performance in demanding applications.

Excellent Electrical Insulation, Heat Resistance, And Mechanical Strength:

When it comes to materials, we use the Shengyi TG170 copper-clad laminate. This material offers excellent electrical insulation, heat resistance, and mechanical strength, making it perfect for automotive applications. With Capel’s 2-layer rigid-flex PCB, you can be confident that your gear shift knob will perform flawlessly and withstand everyday wear and tear.

First, the material provides excellent electrical insulation, ensuring that the PCB maintains proper signal integrity without any interference or leakage. This is critical for automotive shift knobs, as they often require precise and reliable electrical connections to operate smoothly.

Second, Shengyi TG170 laminate has excellent heat resistance. In an automotive environment, the shift knob may be exposed to high temperatures, especially near the engine or in areas exposed to direct sunlight. Our PCBs are designed to withstand these high temperatures without compromising their performance or longevity.

Finally, the material has excellent mechanical strength. In automotive applications, shift knobs may be subject to constant manipulation, vibration, and shock during use. With Shengyi TG170 laminate, our PCBs are able to withstand such mechanical stress and maintain their structural integrity, ensuring reliable and long-lasting performance under these harsh conditions.

Our rigid-flex PCB is not only suitable for car gear shift knobs but is also widely applicable to various vehicles cars made in Japan. The versatility of our PCB allows it to be integrated seamlessly into different automotive systems. Whether you have a sedan, SUV, or sports car, our PCB will fit perfectly and enhance your driving experience.

Customer Satisfaction:

To ensure customer satisfaction, we conduct thorough product testing and quality control. Our team of experts works diligently to deliver reliable and high-performance circuit boards that meet and exceed customer expectations. Our commitment to excellence has made us a trusted partner in the automotive industry.

In conclusion, Capel’s 2-layer rigid-flex PCB is the ultimate solution for car gear shift knobs. With its high adhesion, high reliability, and impressive technical specifications, our PCB will elevate your driving experience. Whether you’re a car enthusiast, a professional racer, or an everyday commuter, our PCB is designed to withstand the demands of modern automotive applications. Choose Capel for a seamless and reliable gear-shifting experience.

Post time: Aug-17-2023

Back