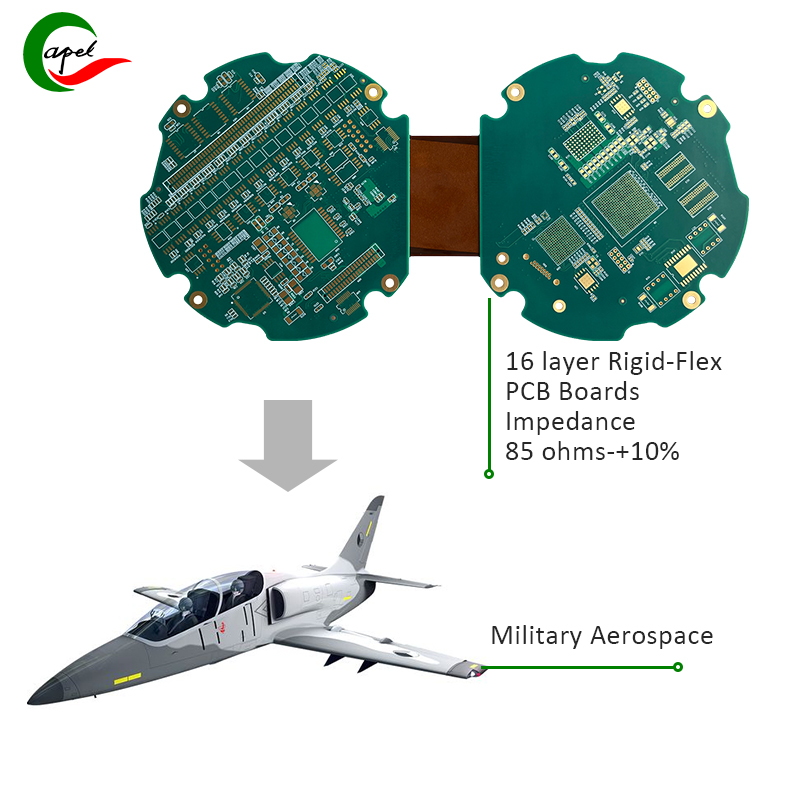

Explore the importance of 16-layer flexible printed circuits (FPC) in meeting the complex needs of the aerospace and defense industry. Learn about this technology, its applications, and the advantages it provides in enhancing the reliability, durability, and performance of electronic systems.

Introduction: Meeting the Changing Needs of Aerospace and Defense

In the rapidly growing aerospace and defense industry, there is an increasing demand for advanced electronic components with high performance, reliability and flexibility. One of the key components is the 16-layer flexible printed circuit (FPC), which has become a game-changing solution to meet the complex needs of aerospace and defense applications. This article takes an in-depth look at the concept of 16-layer FPC, its significance, and how it addresses the specific needs of the aerospace and defense industry.

What is 16-layer FPC?Learn about its intricate design

16-layer FPC is a complex multi-layer flexible printed circuit designed to provide exceptional flexibility and high performance. Unlike traditional rigid PCBs, FPCs are known for their ability to bend, making them ideal for applications where space is limited and complex circuitry is required. The FPC’s 16-layer configuration enables complex and denser circuit designs, enabling it to accommodate complex electronic functions in compact aerospace and defense systems.

Meeting the needs of the aerospace and defense industry: customized solutions

The aerospace and defense industry requires electronic components that can withstand harsh environments, high reliability and superior performance. 16-layer FPC has unique characteristics to meet these specific needs. They excel in environments where space is limited, resistance to vibration and shock is critical, and weight reduction is a priority. In addition, the advanced materials and structure of 16-layer FPC make it suitable for high-frequency signal transmission and have immeasurable value in avionics, radar systems and communication equipment.

Examples of 16-Layer FPC in Aerospace and Defense Applications: Real-World Impact

Avionics systems: Avionics systems integrate a variety of complex functions in a limited space, including navigation, communications and flight control. 16-layer FPC enables the miniaturization of these systems while ensuring high signal integrity and reliability.

Radar systems: Radar systems require complex signal processing and high-frequency transmission capabilities. 16-layer FPC plays a vital role in meeting these requirements, providing the necessary flexibility for installation in curved or irregularly shaped spaces.

Communication equipment: In communication equipment such as satellites, drones and military communication equipment, 16-layer FPC facilitates the transmission of high-speed signals, ensuring seamless and reliable communications in critical aerospace and defense operations.

Benefits of using 16-layer FPC in aerospace and defense: improved efficiency and effectiveness

The application of 16-layer FPC in aerospace and defense brings various benefits that help improve the overall efficiency and effectiveness of electronic systems in these industries. Some key advantages include:

Reliability: The multi-layer design of 16-layer FPC enhances the reliability of electronic connections and reduces the risk of signal attenuation, breakage or short circuits, which is critical in high-stress aerospace and defense environments.

Durability: FPC is engineered to withstand bending and flexing, making it durable and resilient in applications where mechanical stress is prevalent, providing long service life and consistent performance.

Performance: The 16-layer structure allows complex circuit designs to achieve high-speed signal transmission, precise impedance control and minimal signal loss, ultimately enhancing the overall performance of the electronic system.

Weight reduction: Compared to traditional rigid PCBs, FPCs are lightweight, helping to reduce the overall weight of aerospace and defense systems, a key consideration for fuel efficiency and payload capacity.

16 Layer FPC Manufacturing Process for Aerospace and Defense

Conclusion: The future of 16-layer FPC in the aerospace and defense industry

In summary, 16-layer FPC has become a key technology to meet the changing needs of the aerospace and defense industry. Their ability to provide flexibility, reliability and high performance makes them invaluable in applications where space, weight and functionality are critical. Leveraging advanced technologies such as 16-layer FPC is critical to enhancing the capabilities of aerospace and defense systems, ensuring they meet the stringent requirements of modern electronic warfare, avionics and communications systems. As FPC manufacturing and design continue to advance, the aerospace and defense industry is expected to gain greater innovation and value from these complex electronic components.

Post time: Feb-24-2024

Back