Introduce

Understand the importance of 6-layer FPC (Flexible Printed Circuit) in modern electronics and its key role in various applications. Explore the intricacies of 6-layer FPC prototyping and manufacturing, and learn about Capel’s expertise in delivering cutting-edge solutions for electronics design and production.

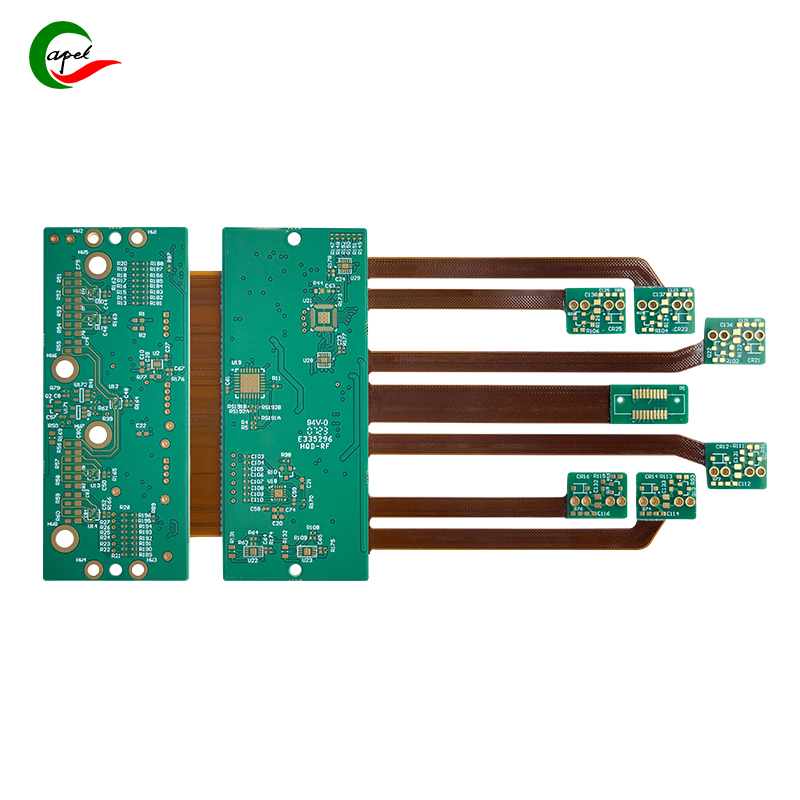

In the electronics field, there is a growing demand for flexible and reliable printed circuit boards (PCBs). As technology and design evolve, the need for advanced PCB solutions has never been more evident. This is where 6-layer FPC (Flexible Printed Circuit) comes into play, providing cutting-edge solutions for complex electronic applications. The importance of flexible PCB prototyping and manufacturing cannot be overstated, and in this article we will explore the complexity of 6-layer FPCs and the critical role they play in the electronics industry. Additionally, we will introduce Capel, a distinguished industry leader with 16 years of experience who is known for his expertise in flexible PCB prototyping and manufacturing.

Learn about 6-layer FPC

Flexible PCB, also known as flex circuit, is a printed circuit board made of flexible high-performance plastic materials. These innovative circuits offer numerous advantages, including complex three-dimensional designs, lightweight properties and exceptional flexibility. 6-layer FPCs have additional complexity that allows for enhanced functionality and versatility. The advantages of using 6-layer FPC are abundant in various applications such as medical equipment, automotive systems and consumer electronics. By providing enhanced connectivity and improved signal integrity, 6-layer FPC has become an indispensable solution in modern electronic design. Companies like Capel continue to push the boundaries of innovation to produce impeccable 6-layer FPC solutions to meet the diverse needs of their customers.

Prototyping process

The importance of prototyping in PCB manufacturing cannot be underestimated. This is a critical stage to test and validate design concepts before series production. In the world of flexible PCBs, the prototyping process plays a key role in ensuring the functionality and durability of the final product. Capel has become an expert in 6-layer FPC prototyping, providing comprehensive services covering design verification, material selection and flexible manufacturing technology. By partnering with Capel, customers gain access to a range of prototyping resources that enable them to turn innovative ideas into reality with precision and efficiency.

Manufacturing flexible circuit boards

Proper manufacturing techniques are critical to producing high-quality flexible circuit boards. 6-layer FPC requires a meticulous manufacturing approach as each layer must be carefully aligned and bonded to ensure optimal performance. Understanding the different manufacturing methods of 6-layer FPC is critical to achieving the desired results. Capel’s advanced manufacturing capabilities, combined with its commitment to quality and precision, make it a trusted partner for customers looking for superior flexible PCB solutions. Their state-of-the-art facilities and dedicated team enable them to meet the complex needs of 6-layer FPC manufacturing, delivering superior results every time.

Factors to consider in flexible PCB manufacturing

When it comes to flexible PCB manufacturing, several key factors must be considered to achieve the desired results. Material selection plays an important role as the choice of flexible substrate and cover material affects the overall performance and durability of the FPC. Design considerations such as routing constraints and stacking configurations need to be carefully evaluated to ensure optimal functionality. In addition, quality assurance and testing are integral components of the manufacturing process, ensuring that the final product meets the highest reliability and performance standards. Capel’s comprehensive approach to flexible PCB manufacturing covers all of these factors, ensuring customers receive a top-notch solution that exceeds expectations.

Choose the right manufacturer

Working with a reliable PCB manufacturer is crucial to the success of any electronics project. A manufacturer’s industry expertise, technical capabilities and commitment to quality are important considerations when selecting a flexible PCB prototyping and manufacturing partner. Capel’s proven track record in flexible PCB manufacturing is a testament to their unwavering dedication to excellence. Capel has become a leading force in the industry due to its wealth of experience, history of successful projects and customer-centric approach. Their unparalleled commitment to innovation and customer satisfaction makes them the perfect choice for customers looking for reliable and high-quality flexible PCB solutions.

6 Layer FPC Fabrication

In summary

The importance of 6-layer FPC in the electronics field cannot be underestimated. Its unparalleled advantages and versatility make it an indispensable solution for a variety of applications. Capel’s 16 years of industry experience, combined with their expertise in flexible PCB prototyping and manufacturing, makes them a leader in the field. We invite anyone in need of flexible PCB prototyping and manufacturing services to consider working with Capel for cutting-edge solutions that deliver superior results. Contact Capel today and experience the difference of working with a true industry pioneer.

Post time: Feb-24-2024

Back