Innovations in the automotive industry continue to reshape the modern world, driving unprecedented advances in safety, efficiency and connectivity. Printed circuit boards (PCBs) are at the center of this transformation, the unsung heroes that power the brains of our vehicles and propel them into the future. Capel is one of the pioneer manufacturers driving this advancement, with over 15 years of expertise in PCB production and a passion for technological innovation. In this comprehensive guide, we’ll explore Capel’s 2-layer flexible PCB’s integral role in advancing automotive technology, revealing the high-precision, high-density and performance-enhancing aspects of this breakthrough product.

Introduction – Pioneering Excellence in PCB Manufacturing

Capel – A pioneer in PCB manufacturing Founded over fifteen years ago, Capel has been at the forefront of PCB manufacturing, leveraging unrivaled expertise and cutting-edge technology to deliver world-class solutions to a variety of industries. With an unwavering commitment to quality and innovation, Capel has solidified its reputation as the partner of choice for businesses seeking quality PCB products that drive technological advancement.

The Emergence of 2-Layer Flexible PCBs in the Automotive Industry

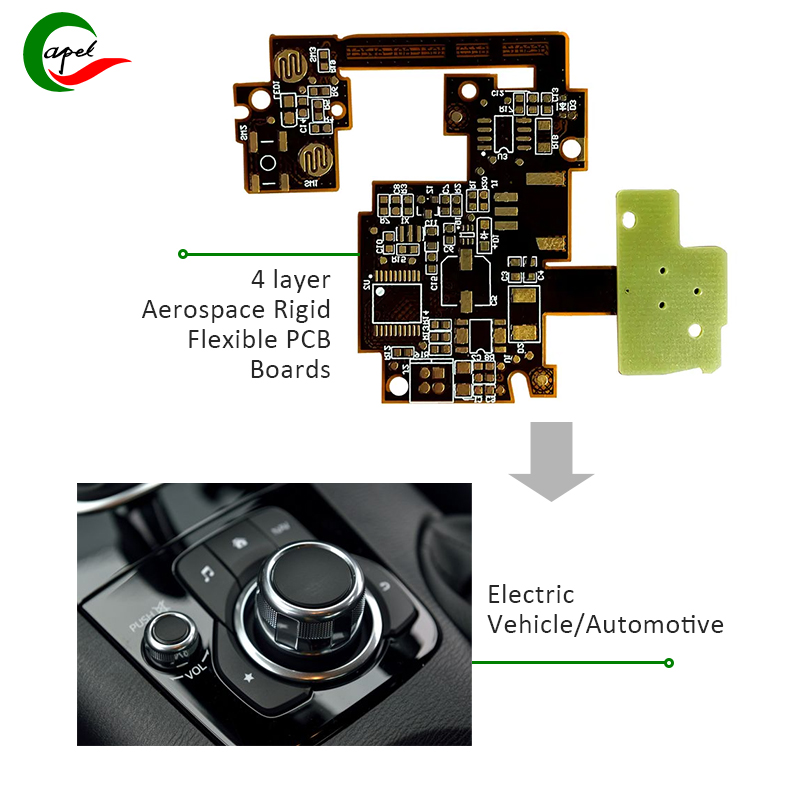

As vehicles evolve from mechanical entities to complex technology hubs, the demand for advanced PCBs continues to increase, especially in the pursuit of flexibility, durability and compactness. This is where Capel’s 2-layer flexible PCB comes into the picture as a game-changing solution that can be seamlessly integrated into the automotive sector, enabling a new stage of technological advancement. From advanced driver assistance systems to in-vehicle infotainment systems, Capel’s 2-layer flexible PCBs advance the performance and efficiency of automotive electronics with their superior functionality.

Product Description – Capel’s 2-Layer Flexible PCB Revealed: A Masterpiece of Precision and Versatility

Capel’s 2-Layer Flexible PCB Revealed: A Masterpiece of Precision and Versatility Capel’s 2-Layer Flexible PCB is engineered and manufactured using a blend of premium materials such as Polyimide (PI), Copper, Adhesives and FR4 for unparalleled Durability and versatility. With line widths and line spacing meticulously crafted to 0.15mm/0.2mm, the structural precision is evident and underlines Capel’s commitment to providing ultra-high precision PCB solutions. The plate thickness of 0.23mm +/- 0.03mm leads the development of automotive electronics, achieving a perfect balance and meeting the strict requirements of the industry.

In addition to size, Capel’s 2-layer flex PCB has a minimum aperture diameter of 0.1mm, further illustrating the product’s exceptional attention to detail. A key aspect of these PCB performance enhancements is the electroless nickel immersion gold (ENIG) surface treatment, which ranges in thickness from 2 to 3 microns, setting a new benchmark for reliability and performance in automotive applications.

The battle cry of high precision and high density

By emphasizing the high-precision capabilities of Capel 2-layer flexible PCBs, engineering teams can easily integrate complex circuits into complex automotive electronics, enabling greater functionality and reduced space requirements. Additionally, the high-density design not only optimizes space utilization but also paves the way for enhanced thermal management, a key element in automotive applications.

Prototyping and Manufacturing Processes – Discover the Path to Manufacturing Excellence with Capel

On the road to manufacturing excellence with Capel Capel provides an end-to-end solution for prototyping and manufacturing of Capel 2-layer flexible PCBs, simplifying complex design, technology evaluation, sourcing, production, assembly, testing and shipping. This comprehensive approach ensures a seamless transition from concept to execution, allowing automotive engineers and designers to tap into the unparalleled expertise of Capel’s engineering and production teams.

At the heart of Capel’s prototyping and manufacturing process is an unwavering dedication to research and development, allowing the company to deliver customized solutions that meet the unique needs of the automotive industry. By partnering with Capel, innovators in the automotive industry can unlock a world of possibilities with cutting-edge PCB solutions tailored to their specific requirements with unwavering precision.

2 Layer Flexible PCB Prototyping and Fabrication Process

Conclusion- Elevate the automotive industry landscape with Capel’s 2-layer flexible PCB

In the ever-evolving field of automotive technology, the role of PCBs has transformed from a mere component to an indispensable enabler of progress. As newfound innovations continue to reshape the automotive industry, Capel has become an indispensable ally, providing a path to high-precision, high-performance 2-layer flexible PCBs that have the potential to redefine automotive electronics.

We invite aspiring automotive technology pioneers to explore the possibilities with Capel and embark on a journey of extraordinary PCB solutions to bring life to their most ambitious designs. Contact Capel today to discover the potential of 2-layer flex PCBs tailored for your automotive innovation journey.

In conclusion, it is clear that Capel’s 2-layer flexible PCB is expected to redefine the automotive field and usher in an era of unprecedented innovation and technological advancement. Capel’s unwavering focus on precision, performance and customization provides automotive engineers and designers with a gateway to new frontiers in automotive electronics. It’s time for automotive technology to push its limits, and Capel’s 2-layer flex PCBs are at the forefront of this transformative journey.

Post time: Jan-29-2024

Back