Introduction to 4 layer rigid-flex board

As an engineer with over 15 years of experience in the 4-layer rigid-flex industry, it is my mission to provide comprehensive insights into the entire 4-layer rigid-flex process from prototype to manufacturing. In this article, I will provide valuable information that is crucial to solving the problems that customers often encounter when dealing with 4-layer rigid-flex board projects, accompanied by classic case analysis.

The emergence of 4 layer rigid-flexible PCB

The need for compact, lightweight and durable electronic devices has driven the development of rigid-flex technology. 4-layer rigid-flex boards, in particular, have been widely used in a variety of applications ranging from consumer electronics to aerospace and medical equipment. The ability to seamlessly integrate multiple functional layers and provide three-dimensional flexibility provides engineers with unprecedented design freedom.

Explore 4 layer Rigid-Flex PCB Prototyping Stage

When engineers begin developing a 4-layer rigid-flex board, the prototyping phase marks a critical first step in the journey. To simplify and speed up this phase, it is essential to work closely with a trusted PCB manufacturer with advanced prototyping capabilities. Thorough design verification and testing at this stage minimizes the potential for costly modifications and delays during manufacturing.

Balanced Rigid-Flex combines flexibility and rigidity in PCB design

One of the main challenges encountered when using 4-layer rigid-flex boards is striking a delicate balance between flexibility and rigidity. It is imperative to achieve optimal performance by carefully selecting materials, defining layer stacks, and carefully considering bend radii. I’ll explore the nuances of material selection and provide actionable insights aimed at optimizing the mechanical, electrical, and thermal performance of 4-layer rigid-flex boards.

Case Study: Overcoming 4 layer Rigid-Flex PCB Manufacturing Challenges

To demonstrate the complexities and complexities of 4-layer rigid-flex manufacturing, I will delve into a classic case study based on a real-life scenario. This case study will reveal the challenges encountered during the manufacturing process and provide practical strategies for overcoming these obstacles. By dissecting the nuances of this case, readers will gain a deeper understanding of potential obstacles and solutions in the manufacturing process.

Ensure signal integrity and reliability of 4 layer rigid-flex PCBs

In the field of 4-layer rigid-flex PCB, ensuring signal integrity and reliability is a key aspect that cannot be ignored. Mitigating signal attenuation, impedance matching and solving thermal management issues are top considerations for engineers to maintain the performance and longevity of the end product. I will provide actionable recommendations to proactively address these factors and maintain the integrity of the design.

Successful integration of 4 layer rigid-flexible PCB

Successful integration of 4-layer rigid-flex boards into various electronic systems depends on careful planning and seamless collaboration. Engineers must carefully ensure that the mechanical, electrical, and thermal aspects are coordinated with the broader system requirements. By developing a holistic view of integration, I’ll provide readers with essential strategies for overcoming integration barriers and simplifying deployment.

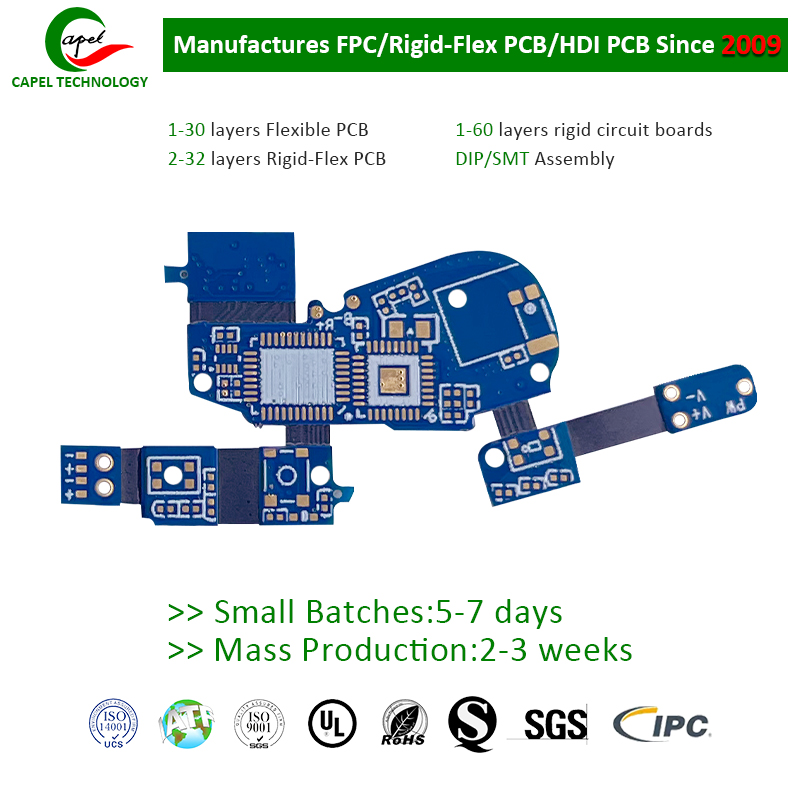

4 Layer Rigid Flex PCB Prototye and Manufacturing Process

Conclusions and future trends of rigid-flex board technology

In summary, the process of taking a 4-layer rigid-flex board from prototype to manufacturing requires a thorough understanding of the complex nuances of design, prototyping, manufacturing, and integration. This article provides insights into the challenges faced at each stage and strategies to address them, supported by classic case analysis. By leveraging my expertise and real-world experience, I strive to provide readers with actionable knowledge to navigate the complexities of 4-layer rigid-flex projects. I firmly believe that this resource will provide a valuable guide for engineers and professionals pursuing excellence in the field of 4-layer rigid-flex PCBs.

Post time: Jan-29-2024

Back