Introduce

The emergence of the Internet of Things (IoT) and wearable devices has revolutionized the way we interact with technology. At the heart of these innovative devices lies the 4-layer flexible printed circuit board (PCB), a key component that enables seamless integration of electronic devices into compact and adaptable form factors. This article delves into the application and significance of 4-layer flexible PCBs in IoT and wearable devices, revealing their powerful capabilities and Capel’s pioneering work in this field.

Learn about 4-layer flexible PCB

The 4-layer flexible PCB is a versatile circuit board that provides enhanced flexibility and reliability, enabling the efficient integration of complex electronic systems into compact and dynamic designs. This flexible PCB variant consists of multiple layers of flexible substrate materials that provide superior electrical performance while adapting to different form factors.

The Importance of 4-Layer Flexible PCB in IoT and Wearable Devices

The prominence of 4-layer flexible PCBs in IoT and wearable devices stems from their ability to withstand mechanical stress, maintain signal integrity, and facilitate miniaturization without compromising performance. As the demand for compact, lightweight and functional devices continues to increase, 4-layer flexible PCBs have become the cornerstone of realizing the vision of connected smart technology.

Capel’s field experience

Capel has become a leading force in the development and implementation of 4-layer flexible PCB solutions for IoT and wearable devices. With a rich history of pioneering innovation and an unwavering commitment to excellence, Capel is at the forefront of driving technological advancement with its expertise in flexible PCB technology.

The key role of 4-layer flexible PCB in IoT and wearable devices

Advantages of using 4-layer flexible PCB

Using 4-layer flexible PCBs in IoT and wearable devices offers many advantages, including enhanced durability, superior signal integrity, and the ability to accommodate complex interconnects in limited space. These properties help improve device functionality and performance, allowing for seamless integration of sensors, processors and communication modules.

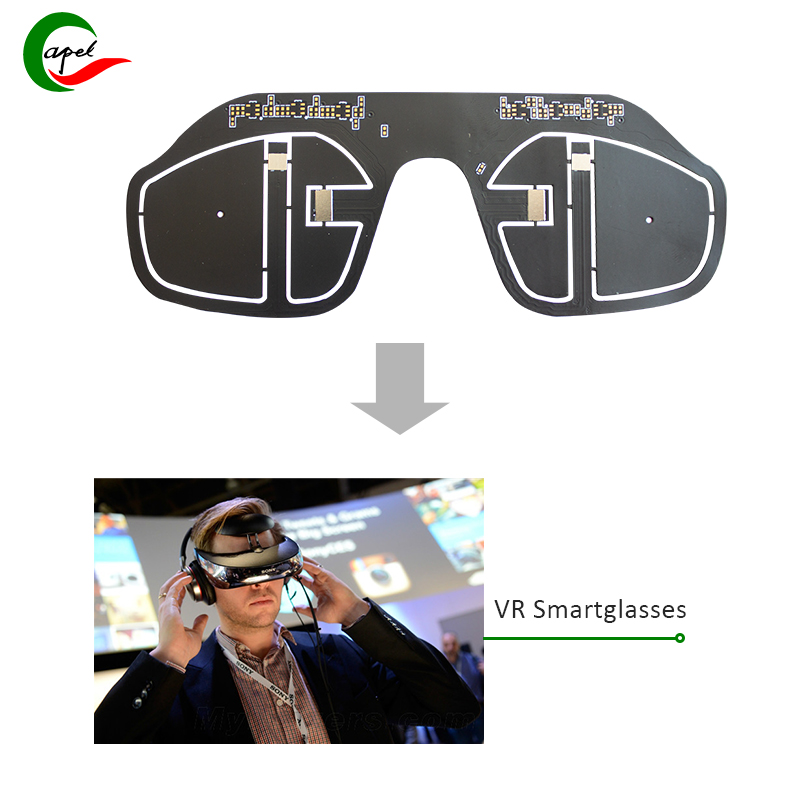

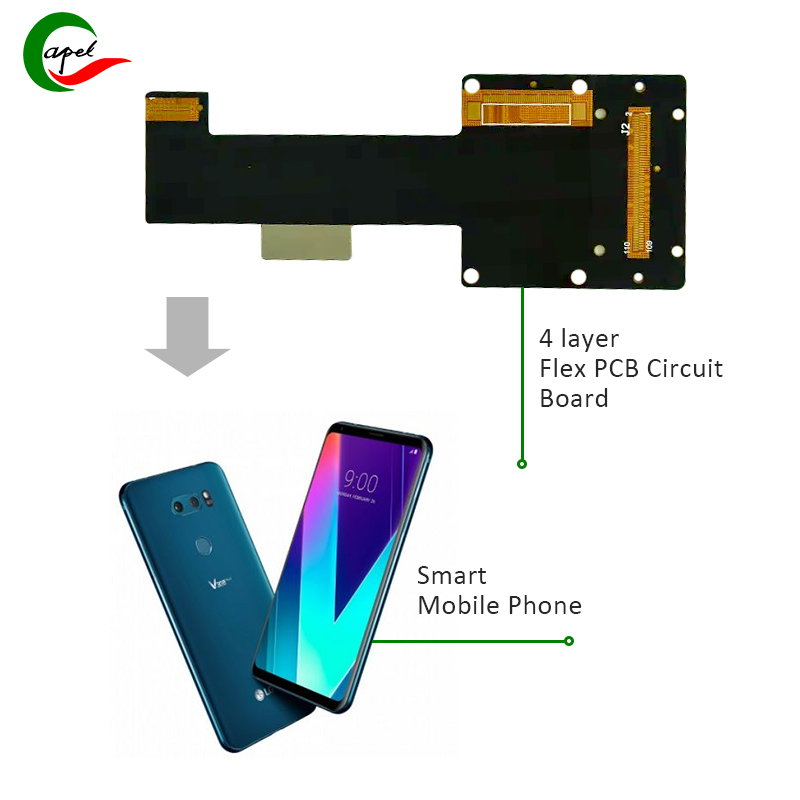

Specific applications and use cases

The applications of 4-layer flexible PCB cover many fields such as healthcare, fitness tracking, industrial automation and consumer electronics. For example, in medical wearables, the flexibility of 4-layer PCBs enables conformal integration into the wearable device, ensuring comfort and accuracy in biometric monitoring. Additionally, in smart clothing and fitness trackers, these PCBs enable unobtrusive integration of electronics while maintaining robust performance.

Impact on IoT and wearable device performance and functionality

The adoption of 4-layer flexible PCBs has redefined the IoT and wearable device landscape, allowing manufacturers to push the boundaries of design and functionality. By introducing flexibility, resilience and efficient interconnectivity, these PCBs pave the way for advanced, user-centric products that integrate seamlessly into everyday life.

Capel’s expertise in 4-layer flexible circuit boards for IoT and wearable devices

Company background and experience

Capel is a pioneer in flexible PCB technology with a rich heritage of driving innovation in IoT and wearable devices. Capel places a strong emphasis on research and development, leveraging its technological prowess to provide cutting-edge solutions to meet the changing needs of the industry.

Success stories and case studies

Capel’s initiatives in the 4-layer flexible PCB space have been successful, as evidenced by its track record of successful collaborations and breakthrough applications in the IoT and wearables space. Through strategic partnerships and a relentless pursuit of excellence, Capel has proven its ability to deliver customized solutions to meet the unique needs of modern technology.

Provide unique features and services

Capel strives to differentiate itself from the competition by providing comprehensive, tailored services for 4-layer flexible PCB solutions. From concept design to prototyping and volume production, Capel’s proficiency in delivering custom, high-quality PCB solutions sets a benchmark of excellence.

Key considerations when using 4-layer flexible PCBs in IoT and wearable devices

Design and manufacturing challenges

Implementing 4-layer flexible PCBs in IoT and wearable devices requires careful attention to design and manufacturing complexities. Consideration of factors such as material selection, mechanical tolerances, and interconnect routing are critical to ensuring optimal functionality and reliability.

Material selection and specifications

Choosing the right materials for a 4-layer flex PCB is critical to determining the performance and longevity of the final product. Capel’s in-depth knowledge of material properties and expertise in sourcing advanced substrates make the company a trusted partner in ensuring seamless material selection and specifications.

Testing and Quality Assurance Process

Capel’s rigorous testing and quality assurance processes ensure the reliability and durability of 4-layer flexible PCBs. By adhering to strict quality standards and conducting thorough validation testing, Capel ensures its PCB solutions meet and exceed industry benchmarks.

Future trends and progress of 4-layer flexible PCB for IoT and wearable devices

Emerging Technologies and Innovation

As the Internet of Things and wearable devices continue to develop, there is a growing need for advanced, high-performance 4-layer flexible PCBs that can adapt to emerging technologies. Capel’s commitment to continuous innovation has made it a pioneer in leveraging emerging technologies to advance flexible PCB solutions.

Potential areas for growth and development

The expanding applications of IoT and wearable devices provide new avenues for growth and development in the flexible PCB sector. Capel remains at the forefront of identifying and exploiting these opportunities, aligning its strategy with advances in smart healthcare, environmental monitoring and the Industrial Internet of Things.

Capel’s role in driving industry progress

Capel’s active participation in industry alliances, research alliances and technology advocacy has made it an influential force in shaping the direction of the flexible PCB landscape. By championing industry progress, Capel bridges the gap between technological innovation and practical application, ensuring its expertise contributes to the collective advancement of IoT and wearables technology.

4-Layer FPC Flexible circuit boards Fabrication Process for IOT and Wearable Devices

In summary

Summary of the advantages and importance of 4-layer flexible PCB in IoT and wearable devices

The use of 4-layer flexible PCBs in IoT and wearable devices has revolutionized the industry by enabling compact, reliable and high-performance electronic solutions. The inherent advantages of 4-layer flexible PCBs, coupled with Capel’s expertise, solidify its role as a cornerstone in the development of cutting-edge IoT and wearable devices.

Capel’s expertise and experience in the field reviewed

Capel’s unwavering commitment to innovation and excellence in 4-layer flex PCB technology demonstrates its position as an industry leader in IoT and wearable devices. By combining technical proficiency, collaboration and forward-thinking strategy, Capel has established a strong presence in driving the advancement of flexible PCB solutions.

Call to Action Ask further or work with Capel

To leverage Capel’s unparalleled expertise in 4-layer flex PCB solutions and unlock the transformative potential of IoT and wearables, we invite industry partners and innovators to join us on a journey with Capel. Together we can shape the future of technology with groundbreaking custom solutions.

In summary, the dynamic landscape of IoT and wearable devices continues to drive innovation in 4-layer flexible PCBs, and under Capel’s leadership, the potential for breakthrough advancements in this area is limitless.

Post time: Feb-26-2024

Back