Explore Capel’s expertise in new energy FPC flexible PCB design for automotive applications. Get an in-depth look at their technical specifications, materials expertise and surface treatments, highlighting their focus on precision, reliability and performance.

Introduce

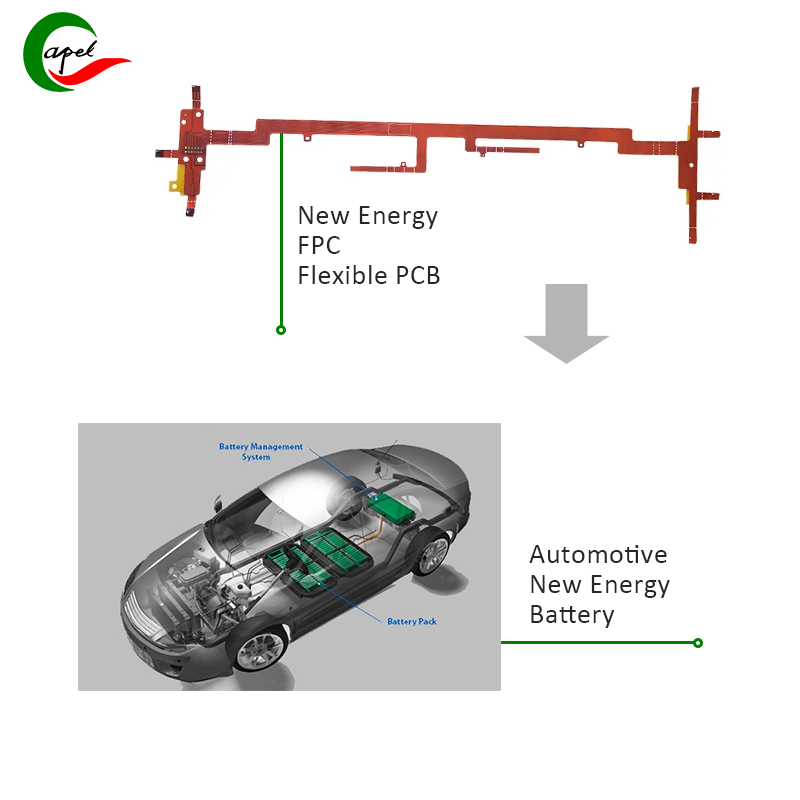

Flexible printed circuit boards (FPC) play a vital role in the design and development of new energy vehicles, especially in applications such as battery protection circuit boards. With a 16-year track record, Capel is at the forefront of innovative FPC design, leveraging robust material properties and impeccable manufacturing techniques to deliver high-performance, reliable and durable FPCs for new energy applications.

In this article, we’ll delve into Capel’s expertise and show how their 2-layer FPC designs using materials such as PI, copper, and adhesives embody precision, quality, and cutting-edge engineering. We will explore technical specifications, applications and industry best practices to make Capel’s FPC the preferred solution for automotive new energy systems.

Technical specifications and materials expertise

Capel’s 2-layer flexible PCBs are carefully designed to meet the demanding requirements of automotive new energy systems, especially in the field of battery protection circuit boards. These FPCs are engineered with a material composition of polyimide (PI), copper and adhesives to ensure elasticity, thermal stability and excellent electrical performance.

Line widths and spacings of 0.2mm/0.25mm, coupled with precise board thicknesses of 0.25mm (+/- 0.03mm), reflect Capel’s commitment to achieving optimal signal integrity and mechanical robustness in FPC designs. In addition, the minimum aperture diameter of 0.1mm demonstrates their commitment to complex, high-precision manufacturing processes, enabling seamless integration of complex components in FPC assemblies.

Excellent surface finish and tolerances

Capel’s FPCs are electroless nickel immersion gold (ENIG) surface treated to provide a uniform and corrosion-resistant finish to the circuit board. The ENIG treatment is available in thicknesses of 2-3uin, ensuring reliable weldability and extended service life, which is critical in the harsh environment of automotive new energy applications.

Additionally, Capel’s unwavering commitment to precision is evident in its exceptional tolerance capabilities. With a tolerance of ±0.1 mm, its FPC meets the most stringent dimensional requirements, ensuring seamless compatibility with complex electronic systems and components.

Application focus: automotive new energy system

The automotive industry is undergoing a dramatic shift towards new energy systems, with a focus on electric and hybrid vehicles. New energy FPC, especially battery protection circuit boards, are crucial to ensuring the safety, efficiency and longevity of these advanced energy storage systems.

Capel’s expertise in designing FPCs customized for automotive new energy applications makes it a trusted partner for automakers and system integrators. With advanced materials, precision manufacturing technology and a deep understanding of automotive requirements, Capel’s FPC supports the seamless integration of battery protection systems, contributing to the overall performance and reliability of new energy vehicles.

New Energy Vehicle FPC Design Manufacturer with 16 Years’ Experience

Excellent new energy vehicle FPC design: Capel’s 16 years of expertise

Capel’s 16 years of project experience in new energy FPC design is a testament to their enduring commitment to excellence, innovation and continuous improvement. Their wealth of knowledge gained through various projects and collaborations resulted in the development of industry-leading FPC solutions that redefined reliability and performance standards.

The pinnacle of their experience is reflected in the careful design of their 2-layer flexible PCB, setting a benchmark for the automotive new energy field. By combining its design expertise with the changing needs of the industry, Capel has built a reputation for delivering FPC solutions that not only meet but exceed customer expectations.

In summary, Capel’s innovative approach to new energy FPC flexible PCB design demonstrates the transformative power of precision engineering and materials expertise. Their unwavering dedication to quality, coupled with a deep understanding of automotive new energy systems, has solidified their position as a pioneer in the field of FPC innovation. Capel’s FPC solutions are a testament to engineering excellence combined with industry foresight in its continued commitment to advancing technology and pushing design boundaries.

Post time: Feb-27-2024

Back