Explore the world of 8-layer flexible printed circuits (FPC) and learn how their advanced capabilities and reliability are revolutionizing the electronics industry. From its importance and benefits to prototyping and manufacturing processes, gain insight into the transformative potential of 8-layer FPC to drive electronics innovation, performance and reliability.

In today’s fast-paced electronics industry, the demand for advanced, reliable electronic equipment continues to surge. 8-layer flexible printed circuits (FPCs) are one of the key components driving innovation and performance in electronic devices. With its complex design and superior performance, 8-layer FPC has become key to the development of cutting-edge electronic products. This article takes a deep dive into the world of 8-layer FPC, exploring its significance, benefits, and the critical role it plays in product development and manufacturing. Drawing on 16 years of expertise in 8-layer flexible PCB prototyping and manufacturing, we’ll unravel the complexities and highlight the technology’s potential to revolutionize electronics.

Introduction to 8-layer FPC

Understanding the fundamentals of 8-layer FPC is critical to understanding its impact on the electronics industry. The core of the 8-layer FPC is a flexible printed circuit board, consisting of eight conductive layers stacked within a flexible substrate. This multi-layer configuration enhances the capabilities of traditional FPCs, thereby enhancing the functionality and performance of electronic devices. The unparalleled versatility and compact design of 8-layer FPC enable integration into a variety of electronic applications ranging from consumer electronics to medical devices and aerospace systems.

The importance of 8-layer FPC lies in its ability to overcome the limitations of traditional PCBs and provide flexible and reliable solutions for complex electronic designs. By providing a greater number of conductive layers, 8-layer FPC helps interconnect various components within a smaller footprint, optimizing space and enhancing overall system performance. 8-layer FPC’s ability to meet the ever-changing demands of modern electronics makes it an indispensable tool for engineers and product developers to achieve breakthroughs in design, functionality and reliability.

Advantages of 8-layer FPC

After delving deeper, it is critical to evaluate the unique advantages that 8-layer FPC brings to electronic devices. The complex architecture of the 8-layer FPC has several key advantages that differ from traditional PCBs. First, the superior interconnect density of 8-layer FPC enables seamless integration of complex circuit designs, thereby improving the functionality and efficiency of electronic devices. The multi-layer construction also enhances signal integrity and reduces electromagnetic interference, ensuring robust performance even in challenging operating environments.

Additionally, 8-layer FPC offers superior flexibility, allowing it to adapt to irregular shapes and fit into tight spaces within electronic components. This flexibility is critical to driving product design innovation, especially in areas where space constraints and weight reduction are critical. In addition, the 8-layer FPC has high thermal stability and is suitable for applications that require extended operating temperatures, further improving the reliability and lifespan of electronic systems.

The use of 8-layer FPC also enhances the manufacturability of electronic devices, reducing assembly complexity and simplifying the production process. The ability to integrate multiple signal and power layers in a compact form factor enables engineers to create complex electronic designs while increasing efficiency and minimizing manufacturing costs.

By leveraging the unique advantages of 8-layer FPC, electronic device manufacturers can take their products to new heights, delivering enhanced performance and reliability while driving innovation in the electronics field.

8-layer FPC prototyping

The 8-layer FPC prototyping process is a critical stage in electronic product development, allowing engineers and designers to validate their concepts and refine their designs before entering the manufacturing phase. Prototyping is a fine-grained but essential step in the product development cycle that enables engineers to thoroughly evaluate the functionality, performance, and manufacturability of their electronic designs.

The 8-layer FPC prototyping process begins with converting design specifications into functional prototypes, typically using computer-aided design (CAD) software to create the initial layout and define the complex interconnections between the eight conductive layers. After the design is complete, the prototyping phase involves the fabrication of small batches of 8-layer FPC units for rigorous testing and validation. This stage allows engineers to evaluate the electrical integrity, thermal performance and mechanical stability of the flex circuit, providing valuable insights for further improvements.

The importance of 8-layer FPC prototyping cannot be overstated as it is an essential tool for identifying and correcting design flaws early in the development cycle. By subjecting prototypes to rigorous testing and validation procedures, potential issues can be proactively addressed, saving time and resources in subsequent manufacturing stages.

A comprehensive approach to 8-layer FPC prototyping requires collaboration between design engineers, prototype manufacturers, and test professionals to ensure that the final design meets the stringent performance and reliability requirements imposed by the application. Through meticulous attention to detail and thorough validation, the prototyping phase lays the foundation for a successful transition to large-scale manufacturing, ensuring that the final product meets the highest quality and reliability standards.

8-layer FPC manufacturing

With the prototyping phase over, the focus shifts to 8-layer FPC manufacturing, where the proven design is converted into a production-ready flexible circuit board. The 8-layer FPC manufacturing process consists of a complex series of steps designed to achieve precise layer alignment, impeccable electrical connections, and superior structural integrity that are critical to delivering reliable, high-performance electronic solutions.

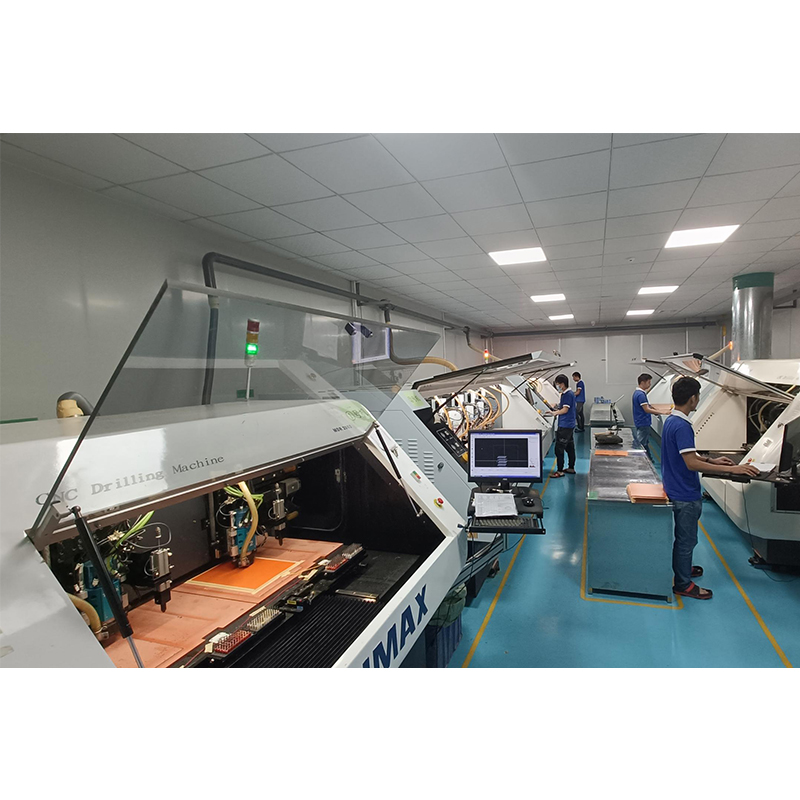

The manufacturing process of the 8-layer FPC starts with the preparation of the flexible substrate, which is the basis for assembling the conductive layers. The precise lamination of the substrate and conductive layers is a critical stage that requires meticulous attention to detail to ensure optimal interlayer adhesion and electrical performance. Advanced manufacturing techniques such as laser drilling and precision etching are used to create complex circuit patterns that define the functionality of the 8-layer FPC.

Ensuring the structural integrity and durability of the 8-layer FPC is critical and is achieved through strict quality control measures and compliance with industry-leading manufacturing standards. The final stage of manufacturing involves applying protective coatings and surface treatments to protect the circuitry from environmental factors such as moisture, dust and mechanical stress, further increasing the reliability and longevity of the flexible PCB.

The 8-layer FPC is manufactured using a comprehensive approach, with each stage carefully planned to translate design intent into physical reality. Through the seamless coordination of advanced manufacturing processes and stringent quality assurance protocols, manufacturers can deliver 8-layer FPC solutions that embody uncompromising quality, performance and reliability, laying the foundation for the deployment of next-generation electronics.

Choosing the right 8-layer FPC manufacturer

Choosing the ideal 8-layer FPC manufacturer is a critical decision that has a significant impact on the success of electronic product development. The process of selecting a reliable and capable manufacturer requires careful evaluation of a variety of factors to ensure that the end result meets the application’s stringent performance and reliability requirements.

One of the main considerations when choosing an 8-layer FPC manufacturer is its technical expertise and industry experience. Manufacturers with a proven track record in producing high-performance, reliable 8-layer FPC solutions emphasize their ability to meet the demanding needs of modern electronic designs. The integration of cutting-edge manufacturing technology and advanced production facilities is crucial to seamlessly realize complex and complex 8-layer FPC designs with uncompromising precision and quality.

Additionally, commitment to quality and adherence to industry standards are key pillars that distinguish reputable 8-layer FPC manufacturers. Adopting a strong quality management system and maintaining certifications such as ISO 9001 and AS9100 demonstrate a manufacturer’s commitment to excellence and guarantee top performance and reliability of their products.

Seamless collaboration between design teams and manufacturing partners is another key aspect to consider. Manufacturers actively collaborate with design engineers to provide valuable insights and suggestions for design optimization, creating a collaborative environment and ultimately creating truly innovative 8-layer FPC solutions. This collaborative approach significantly simplifies the transition from prototyping to manufacturing, ensuring a smooth and efficient production process.

Additionally, a commitment to supply chain transparency and seamless logistics operations is critical to ensuring consistent availability and timely delivery of 8-layer FPC solutions. Reliable manufacturers with strong supply chain management capabilities can handle the complexities of sourcing materials and components, reduce potential risks and ensure a continuous flow of production, thereby supporting the timely realization of electronic products.

By carefully evaluating these critical factors and establishing partnerships with reputable and capable 8-layer FPC manufacturers, electronic device developers can achieve success by leveraging the expertise and capabilities of their manufacturing partners to achieve breakthroughs in electronic design and innovation.

Case Study: Successful Implementation of 8-Layer FPC

The potential of 8-layer FPC to support innovative electronic designs and drive performance and reliability is best exemplified through real-world case studies demonstrating its transformative impact. One example is the successful implementation of 8-layer FPC in the development of advanced medical imaging systems, revolutionizing diagnostic capabilities and improving patient care.

In this case study, the integration of an 8-layer FPC allows the creation of complex and compact interconnects between various imaging sensors and signal processing modules within a medical imaging system. The enhanced flexibility and interconnect density of 8-layer FPC facilitates seamless integration of complex circuits, enabling the development of ultra-compact portable imaging solutions without compromising performance or reliability.

The use of 8-layer FPC enables medical imaging systems to achieve unparalleled signal integrity and electrical performance, which is critical for generating high-resolution diagnostic images with superior clarity and accuracy. The flexibility of 8-layer FPC has proven critical in adapting to the various form factors and space constraints inherent in medical device design, providing designers with unparalleled freedom to create innovative and ergonomic solutions.

Following the prototyping phase, a successful transition to 8-layer FPC manufacturing ensures seamless implementation of advanced medical imaging systems. The partnership between the design team and an experienced 8-layer FPC manufacturer played a key role in refining the design, optimizing the manufacturing process, and delivering a high-performance solution that exceeds industry expectations.

The far-reaching impact of 8-layer FPC in this case study highlights its potential to revolutionize electronics and drive innovation and performance in professional applications. By leveraging the benefits of 8-layer FPC, electronic device developers can open up new areas of product development and deliver transformative solutions that improve performance, reliability and user experience.

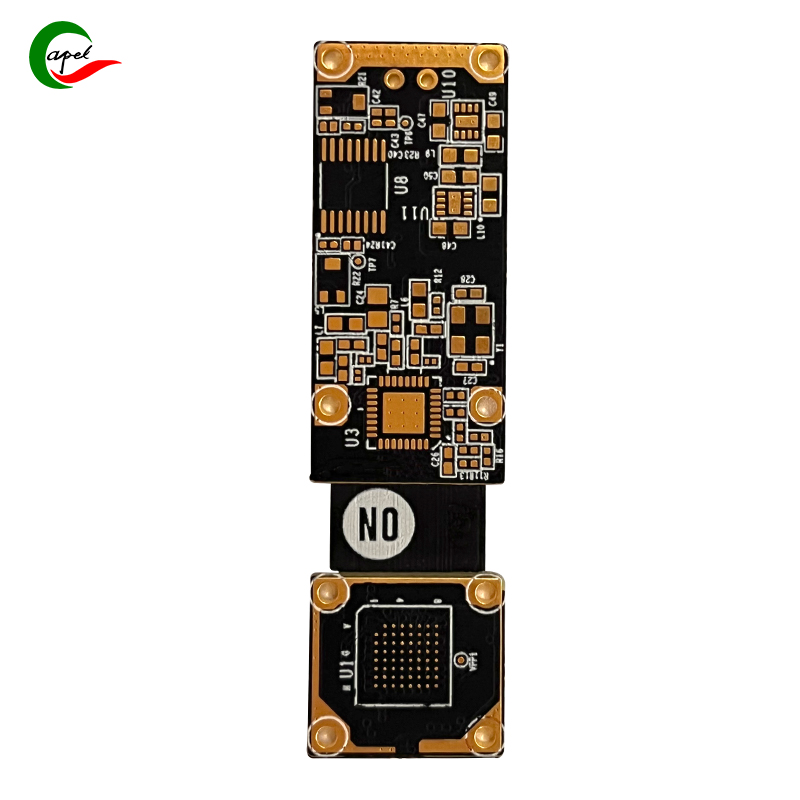

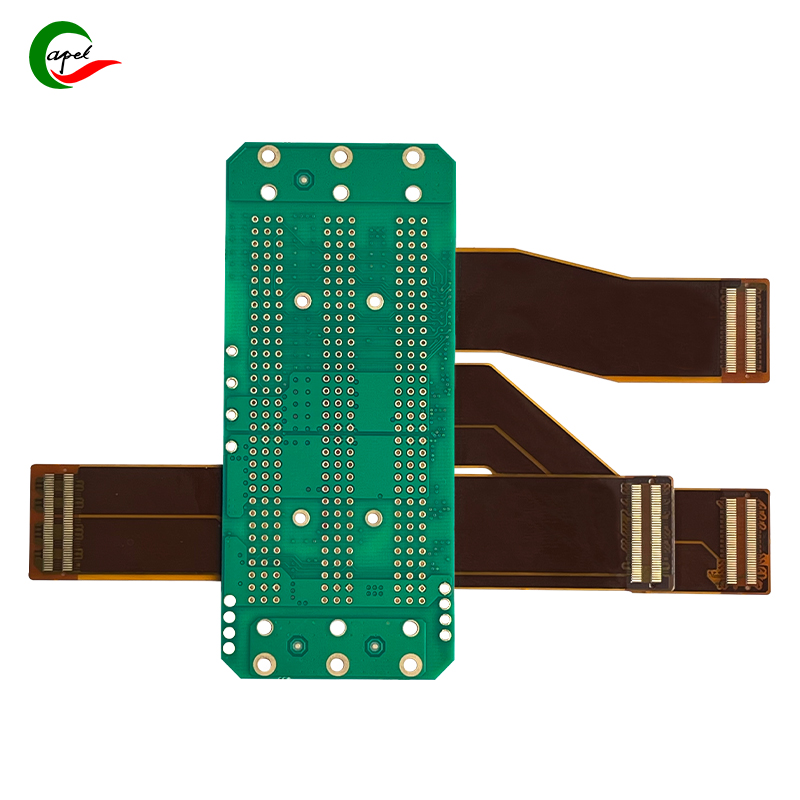

8 Layer FPC Prototype and Fabrication Process

In summary

The evolution of the electronics industry has witnessed the continued importance of 8-layer FPC in driving innovation, performance and reliability. As electronic devices continue to increase in complexity and functionality, 8-layer FPCs continue to play a critical role in realizing the grand vision of cutting-edge electronic designs.

By understanding the fundamental significance and unique advantages of 8-layer FPC, electronic device developers can harness its transformative potential to create breakthrough solutions that redefine industry standards. The meticulous attention to detail and rigorous verification process inherent in 8-layer FPC prototyping provide the foundation for a seamless transition to manufacturing, ensuring the final product meets the highest standards of performance, quality and reliability.

Partnering with a reputable and strong 8-layer FPC manufacturer enables electronic device developers to realize their vision, leveraging the expertise and capabilities of their manufacturing partners to achieve breakthroughs in electronic design and innovation.

In summary, adopting 8-layer FPC in product development not only enhances performance and functionality, but also enhances the overall user experience, laying the foundation for a new era of electronic solutions. As the electronics industry continues to expand and develop, the indelible impact of 8-layer FPC on next-generation electronic design cannot be underestimated, cementing its status as a game-changing technology that is expected to shape the future of electronic products. Realizing the potential of 8-layer FPC in product development is a strategic mission that provides a transformative path to innovation, performance and reliability in a dynamic electronics world.

With a deep understanding of the importance and impact of 8-layer FPC, electronic device developers are ready to embark on a journey of innovation, leveraging the advanced capabilities and transformative potential of 8-layer FPC to push their electronic products to new heights and drive the industry Advance and redefine the future of the electronics industry.

In summary, the transformative potential of 8-layer FPC remains the cornerstone of electronics innovation, delivering unparalleled functionality and reliability, driving the vitality of the electronics industry and changing the landscape of electronics design and manufacturing.

In summary, the transformative potential of 8-layer FPC is the cornerstone of electronic innovation, providing unparalleled functionality and reliability, driving the vitality of the electronics industry, and changing the landscape of electronics design and manufacturing.

Post time: Mar-02-2024

Back