This sounds like an impressive application for flex PCB! The deformable ultrasonic transducer (TUT) was implemented using a 15-meter-long flexible circuit board, demonstrating a high degree of flexibility and adaptability in the design.

What is the flex PCB ?

A flexible circuit board, also known as a flexible PCB, is a printed circuit board (PCB) that can be bent, twisted, and molded into various shapes. Unlike rigid PCBs, which are made of rigid materials like fiberglass, flex PCBs are made of flexible materials like polyimide or polyester.

Flexible PCBs have several advantages over rigid PCBs.

They can be designed to fit tight spaces or conform to irregular shapes, making them ideal for applications with limited space or complex designs. Flexible printed circuit boards are lightweight and can be folded or rolled, making them easier to transport and install. Flexible printed circuit boards are commonly used in a variety of industries including automotive, aerospace, consumer electronics, medical devices, and more. They are commonly found in devices that require continuous bending or movement, such as smartphones, tablets, wearables, and automotive sensors. The manufacturing process of flex PCBs is similar to that of rigid PCBs, but requires additional steps for flexibility. Flexible substrates are coated with a conductive material, usually copper, and then a protective layer is added for durability. Circuit traces and components are then etched onto the flexible substrate using a combination of chemical and mechanical processes.

Flexible circuit boards are a versatile and reliable solution for electronic devices that require flexibility and durability. Their ability to adapt to different shapes and withstand repeated bending makes them ideal for a variety of applications.

PCB Flex Applicated in Aerospace TUT

A deformable ultrasonic transducer (TUT) is an ultrasonic transducer capable of changing shape. Traditional ultrasonic transducers generally have a fixed shape, while TUT uses flexible materials and a deformable structure design, allowing it to change shape and angle according to needs. The deformable design of TUT can be realized by controller or electronic system. By changing the shape of the TUT, the ultrasonic emission and reception angles can be adjusted to adapt to different usage scenarios and application requirements.

For example, in the field of medicine, TUT can adjust its shape according to the needs of the patient’s body size and the examination site, so as to achieve more accurate and effective ultrasound diagnosis. In addition, the deformable nature of TUT also helps to address the limitations of conventional ultrasound transducers in terms of space constraints and adaptability to curved surfaces. For example, in special applications such as robots or drones, the TUT can adaptively change its shape according to the shape of the body to achieve more flexible ultrasonic transmission and detection.

The deformable ultrasonic transducer (TUT) is an ultrasonic conversion device that can change its shape according to the needs. Its deformable design makes it promising for a wide range of applications in medical, industrial and robotics, and brings new possibilities for the development of ultrasound technology.

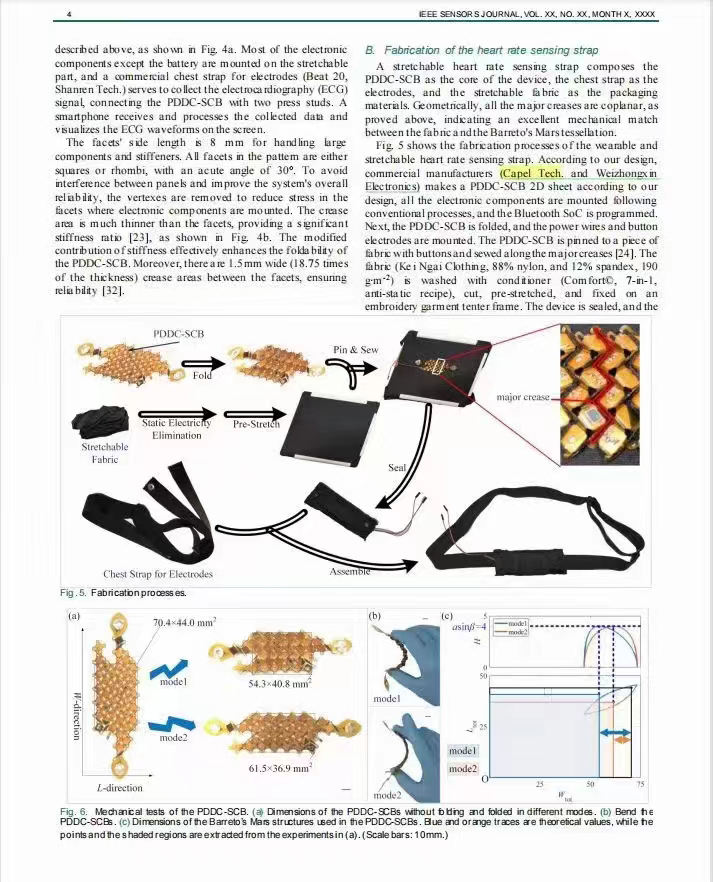

Case Study of the Collaboration Project between Capel Technology Limited and the University of Hong Kong:

We warmly welcome Dr. Li Yongkai and Dr. Wang Ruoqin from Hong Kong University of Science and Technology and their team to visit our company Capel for guidance and technical exchange, and jointly witness the success of our cooperation project , and the successful completion of the 15-meter special ultra-long Flexible Circuit Board.

After receiving the project requirements of the ultra-long Flexible Circuit Boards from Dr. Li and Dr. Wang, our company organized a technical team. Through detailed technical communication with Dr. Li and Dr. Wang, we understood the detailed needs of the customers. Through internal technical discussion and analysis, the technical team formulated a detailed production plan. Special extra long Flexible Circuit Board of 15 meters were successfully produced.

Successfully witnessed the application of a 15-meter-long flexible circuit board in the innovative transformable ultrasonic transducer(TUT). That can be bent approximately 4000 times with a testing bend radius of 0.5 mm. The folding process of this flexible circuit board can be precisely controlled to achieve various forms, which are critical for the transforming process of TUT.

The Innovation of the 15-meter Flexible Circuit Board in Aerospace TUT

Traditional flexible circuit boards are often limited in size, and long-dimension design is of great significance in aerospace. The 15-meter flexible circuit board can better adapt to the design requirements of large aircraft, satellites and other aerospace vehicles, providing a wider connection and wiring space.

High-reliability design: Electronic equipment in aerospace has very high reliability requirements, and any failure may lead to serious consequences. During the design and manufacturing process of the 15-meter flexible circuit board, the requirements of high reliability are considered, and advanced materials and processes are used to ensure stable electrical connection and transmission performance under extreme conditions.

High temperature resistance performance: Aerospace vehicles will face extremely high temperatures in extreme environments such as reentry into the atmosphere or outer space in the atmosphere. The 15-meter flexible circuit board maintains good electrical performance and structural stability in a high-temperature environment through the selection of high-temperature-resistant materials and optimized thermal management design, effectively ensuring the normal operation of electronic equipment.

Flexibility: Aerospace vehicles experience a lot of motion and vibration during flight, so circuit boards need to be able to adapt to bending and complex spatial shapes. The 15-meter flexible circuit board adopts flexible materials and design, so that it can maintain stable electrical connection and mechanical performance when it is bent and folded, ensuring the reliability of signal transmission.

High-Density Connections: Electronic equipment in aerospace vehicles usually needs to process a large amount of data and signals, so it needs to be capable of high-density connections. The 15-meter flexible circuit board adopts advanced printing and assembly technology, which can achieve higher circuit density and richer connection interfaces, and provide more signal transmission channels and interface options.

Lightweight design: The weight of aerospace vehicles has a significant impact on performance and fuel consumption, so lightweight design has always been the focus of aerospace engineers. Due to the use of flexible materials and thin design, the 15-meter flexible circuit board is lighter than traditional rigid circuit boards, which can reduce the weight burden of aerospace vehicles and improve overall efficiency and performance.

Resistance to electromagnetic interference: The electronic equipment of aerospace vehicles often faces strong electromagnetic interference, such as lightning and strong electromagnetic fields. The 15-meter flexible circuit board can effectively resist external electromagnetic interference through excellent electromagnetic shielding and anti-interference design, ensure the stable operation of the circuit, and improve the anti-interference ability of the spacecraft.

Flexible system integration: Aerospace vehicles usually consist of multiple subsystems, such as communication systems, navigation systems, control systems, etc., which need to be integrated and interconnected. The flexibility and customizability of the 15-meter flexible circuit board enable it to adapt to the connection needs between different subsystems, achieve a high degree of integration, and simplify the design and manufacturing process of spacecraft.

The success of this Flexible Circuit Board marks another breakthrough in our technology, and the production capacity of the company has been greatly improved, which has accumulated valuable experience for the production of the company.

Post time: Jun-12-2023

Back