In this blog post, we will explore this issue in detail and shed light on rigid-flex compatibility with SMT.

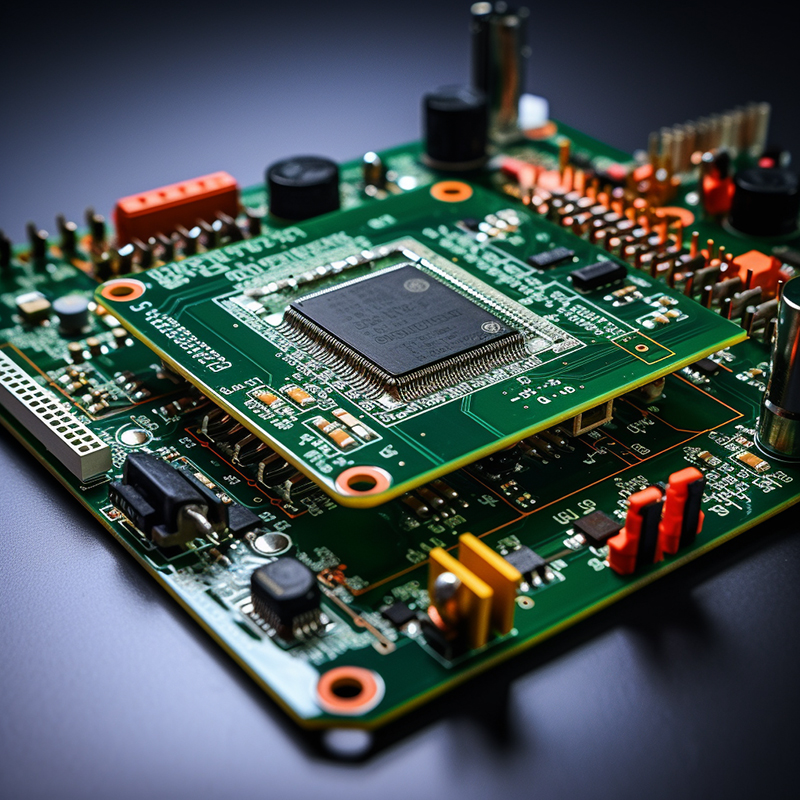

Rigid-flex circuit boards have made great strides in revolutionizing the world of electronics manufacturing. These advanced circuit boards combine the advantages of rigid and flexible circuits, making them highly versatile and suitable for a wide range of applications. A common question that often comes up is whether rigid-flex circuit boards are compatible with surface mount technology (SMT).

To understand the compatibility aspect, we first explain what rigid-flex boards are and how they differ from traditional boards. Rigid-flex panels are made up of rigid and flexible sections, allowing them to bend, twist or fold to fit into tight spaces or unconventional designs. This flexibility increases reliability, reduces assembly errors and improves durability compared to traditional PCBs.

Now, back to the main question – whether rigid-flex circuit boards are compatible with SMT technology. The answer is yes! Rigid-flex boards are fully compatible with SMT, making them ideal for electronics manufacturers looking to take advantage of rigid and flexible circuits and state-of-the-art surface mount technology.

There are several reasons why rigid-flex boards work seamlessly with SMT. First, the rigid portion of the circuit board supports the SMT components, providing a stable, secure foundation for installation. This ensures that components are securely held in place during welding and assembly, minimizing the risk of misalignment or damage.

Second, the flexible portion of the board allows efficient trace routing and interconnection between different parts and components. This freedom of movement and routing flexibility provided by the flexible portion of the circuit board simplifies the design and assembly process and increases overall manufacturing efficiency.

Another advantage of SMT-compatible rigid-flex boards is the ability to reduce the need for connectors and interconnect cables. The flexible portion of the circuit board can replace traditional wires or cables without the need for additional connectors, allowing for a more streamlined and compact design. Not only does this save space, it also improves signal integrity and reduces the potential for electrical noise or interference.

In addition, rigid-flex boards provide better signal transmission capabilities compared to rigid boards. The flexible portion of the circuit board acts as an excellent impedance matching conduit, ensuring smooth signal flow and reducing the risk of signal loss or distortion. This is especially important for high-frequency or high-speed applications where signal quality is critical.

To sum up, rigid-flex circuit boards are indeed compatible with surface mount technology (SMT). Their unique combination of rigid and flexible circuits enables efficient assembly, improved reliability and enhanced design flexibility. By leveraging the advantages of rigid and flexible components, electronics manufacturers can achieve compact, robust, and high-performance electronic devices.

When considering using rigid-flex in SMT, it is important to work with an experienced and knowledgeable PCB manufacturer who specializes in high-quality rigid-flex. These manufacturers can provide valuable insights, design guidance and production expertise to ensure seamless integration of SMT components on rigid-flex boards.

In summary

rigid-flex circuit boards offer electronics manufacturers a game-changing solution. Their compatibility with SMT technology opens up new possibilities for creating complex and reliable electronic devices. Whether in aerospace, medical, automotive, or any other industry where space and reliability are critical, rigid-flex boards with SMT compatibility are certainly worth considering. Embracing this technological advancement can provide a competitive advantage and pave the way for innovation in the fast-paced electronics world.

Post time: Sep-18-2023

Back