In recent years, rigid-flex PCBs have gained popularity due to their unique designs and ability to handle specific challenges posed by high-vibration environments. In this blog post, we will explore the advantages of using rigid-flex PCBs in such environments and discuss how they can improve the reliability and performance of electronic devices.

In today’s world, where electronic devices are used in a wide range of applications, ensuring the reliability and durability of these devices has become critical. One of the key factors to consider is the performance of printed circuit boards (PCBs) in high-vibration environments. Particularly in industries such as aerospace, automotive and medical, equipment is often subject to movement and vibration, so it is important to use PCBs that can withstand such conditions.

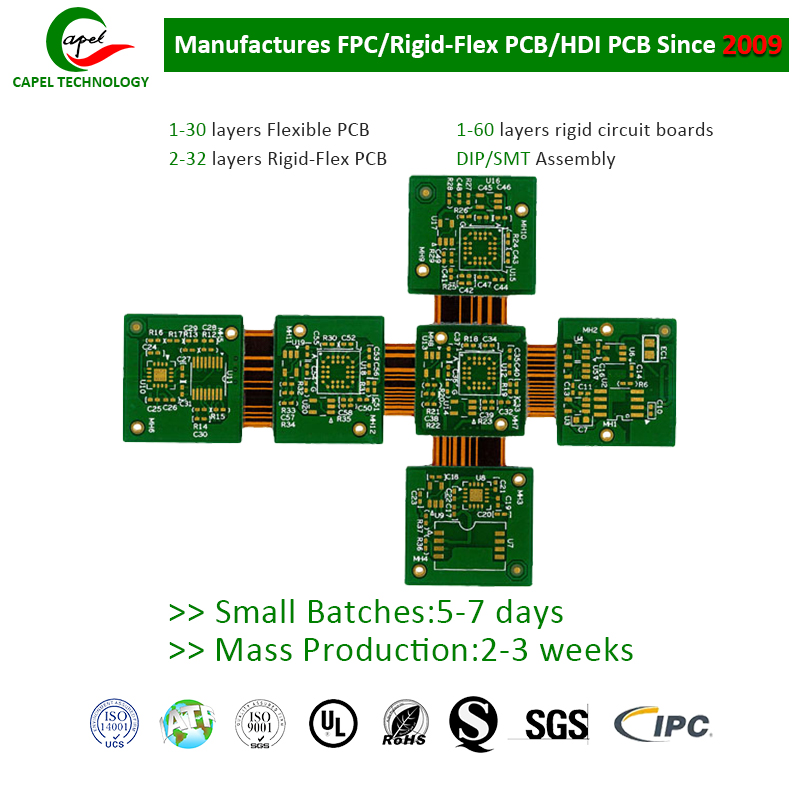

1. Introduction to rigid-flex board

Rigid-flex PCB is a hybrid of traditional rigid PCB and flexible circuit board. They consist of rigid and flexible sections that are interconnected by plated through holes, enabling three-dimensional (3D) designs. This unique construction offers many advantages, including improved space utilization, reduced weight, enhanced durability, and flexibility during installation.

2. Enhance mechanical stability

One of the main advantages of rigid-flex PCBs is their enhanced mechanical stability. The combination of rigid and flexible materials allows them to withstand high levels of vibration and shock without affecting their structural integrity. This is especially important in high-vibration environments where traditional rigid PCBs or flexible circuit boards can fail due to their inherent limitations.

3. Reduce interconnect failures

In high-vibration environments, interconnect failure is a significant issue because it can lead to signal integrity issues or entire device failure. Rigid-flex PCBs solve this problem by providing a strong connection between rigid and flexible parts. The use of plated through holes not only improves mechanical reliability, but also ensures a reliable electrical connection and reduces the risk of interconnect failure.

4. Improve design flexibility

The 3D design capabilities of rigid-flex PCBs provide unparalleled design flexibility, allowing engineers to optimize the layout of electronic components. This is critical in high-vibration environments as it allows components to be placed in specific locations, improving the overall performance and reliability of the equipment. Additionally, eliminating bulky connectors and cables simplifies the overall design, resulting in cost savings and better use of space.

5. High-density integration

With the continuous miniaturization of electronic devices, it has become inevitable to achieve high-density integration. Rigid-flex PCBs excel in this regard because they allow components to be integrated on both sides of the board, thus maximizing space utilization. The ability to stack multiple layers of rigid and flexible materials further enhances integration capabilities, making it easier to accommodate complex circuits in high-vibration environments.

6. High vibration material selection

When using rigid-flex PCBs in high-vibration environments, choosing the right materials becomes critical. Material selection should consider factors such as mechanical strength, thermal stability and resistance to vibration fatigue. For example, using polyimide films with high glass transition temperatures can enhance PCB durability and performance under extreme conditions.

In Summary

Using rigid-flex PCBs in high-vibration environments offers significant advantages in terms of mechanical stability, reduced interconnect failures, increased design flexibility, and high-density integration. These advantages make them ideal for industries where equipment frequently moves and vibrates. However, it is important to carefully select appropriate materials and design considerations to ensure optimal performance and reliability. By leveraging the unique capabilities of rigid-flex PCBs, engineers can design electronic devices that can withstand the challenges of high-vibration environments and deliver superior performance.

Post time: Sep-18-2023

Back