Explore the evolution of automotive flex PCB technology with Capel manufacturer, which has 16 years of expertise in design, prototyping and manufacturing. An in-depth look at 8-layer HDI second-order rigid-flex PCBs, precision material compositions, advanced The manufacturing process and relentless innovative spirit are reflected in this comprehensive article.

Introduce:

In the era of advanced automotive technology, the demand for reliable, high-performance electronic systems has skyrocketed. Rigid-flex printed circuit boards (PCBs) play a vital role in meeting this need, providing the necessary flexibility, durability and space efficiency for automotive applications. With 16 years of expertise in automotive flexible PCB design, prototyping and manufacturing, the Capel facility is at the forefront of this technological development. In this comprehensive article, we’ll delve into the complex world of automotive flexible PCBs, exploring Capel’s remarkable journey and the remarkable technological advancements that propelled them to the pinnacle of flexible PCB innovation. From understanding the complexity of 8-layer HDI second-order rigid-flex PCBs, to meticulous material composition, precise dimensions and advanced surface treatment technology, we will uncover the remarkable mosaic that defines Capel’s capabilities in automotive flexible PCB technology.

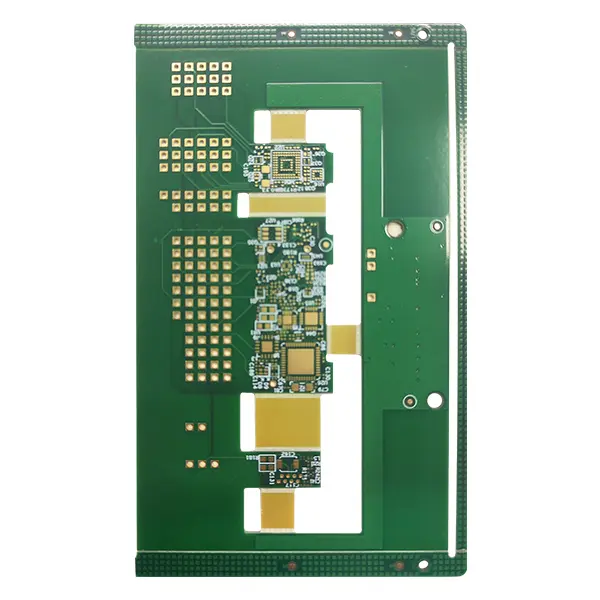

Chapter 1: Uncovering the complexity of 8-layer HDI second-order rigid-flex PCB

Flexible PCBs are indispensable components in modern automotive systems for a variety of applications requiring superior reliability and performance. The 8-layer HDI second-level hard-software PCB sets new standards in complexity, requiring a harmonious fusion of cutting-edge technology and meticulous craftsmanship. Capel’s skilled engineers have mastered the art of designing and manufacturing these complex PCBs, demonstrating unparalleled expertise in layer stackup design, via structure and material selection. With a clear understanding of the thermal, mechanical and electrical requirements of automotive applications, Capel ensures that every aspect of PCB design meets the stringent requirements of the automotive industry.

Chapter 2: Material Composition Accuracy and Dimensional Integrity

The materials used in automotive flexible PCBs play a key role in determining their performance, reliability and longevity. Capel’s use of polyimide (PI), copper, adhesives and FR4 embodies the essence of durability and functionality. Each material is carefully selected to withstand the harsh operating conditions prevalent in automotive environments, ensuring the flexible PCB delivers superior performance in all conditions. In addition, precise line width, line spacing and board thickness specifications highlight Capel’s strong commitment to dimensional accuracy and consistency, which are essential attributes to ensure proper functionality and compatibility within automotive systems.

Chapter 3: Complexities of Hole Design and Surface Preparation

Complex hole designs in flexible PCBs are critical to ensuring the interconnectivity and functionality of electronic components. Capel’s expertise in designing and implementing blind, buried, and plated via fills underscores their commitment to achieving optimal signal integrity and electrical performance. In addition, the electroless nickel immersion gold (ENIG) surface treatment technology with 2-3uin ultra-thin coating demonstrates Capel’s commitment to improving the reliability, solderability and overall quality of flexible PCBs for automotive applications.

Chapter 4: Pioneering Advanced Manufacturing Processes and Tolerance Control

Manufacturing automotive flexible PCBs requires the seamless integration of advanced processes and strict quality control measures. Capel’s 16 years of experience have resulted in manufacturing capabilities characterized by precision, reliability and efficiency. The company adheres to tight tolerances, with a tolerance grade of ±0.1mm, which underlines their unwavering commitment to uncompromising precision and quality with every flexible PCB they produce. From drilling to plating, imaging to lamination and final assembly, Capel’s manufacturing process embodies technological innovation and operational excellence.

Chapter 5 The essence of 16 years: proficiency, professionalism and innovation

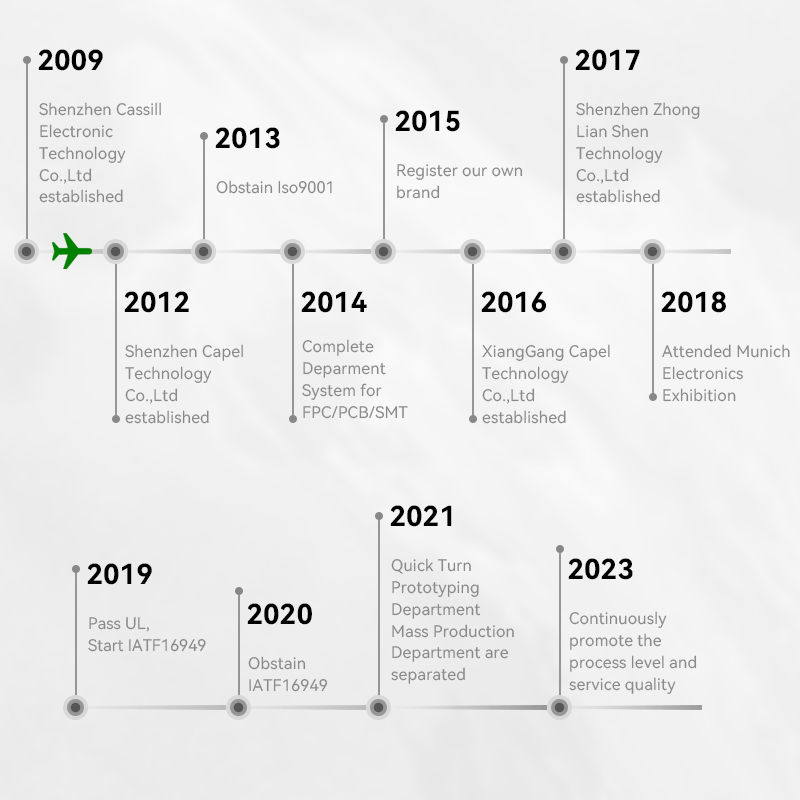

The Capel factory’s 16-year history as an automotive flexible PCB manufacturer is a testament to their unwavering commitment to excellence, innovation and customer satisfaction. The accumulated expertise in automotive flexible PCB design, prototyping and manufacturing serves as a beacon of professionalism and competence, solidifying their position as an industry leader. The synergy of Capel’s superior process capabilities, advanced technology and commitment to continuous improvement has made the company a trusted partner to automotive OEMs and suppliers worldwide.

Automotive Flex PCB Design & Prototyping and Fabrication Process

Chapter 6: Conclusion: The future of automotive flexible PCBs and Capel’s indomitable spirit

As automotive technology continues to advance at an unprecedented rate, the role of flexible PCBs becomes increasingly indispensable. With 16 years of expertise, the Capel factory is at the forefront of this technological development, driven by a relentless spirit of innovation, precision and adaptability. The entire process from design conceptualization to prototyping and final manufacturing reflects Capel’s unwavering commitment to technological advancement and customer satisfaction. As the automotive industry moves toward a future characterized by autonomy, connectivity, and electrification, Capel’s expertise will undoubtedly continue to shape and redefine the field of automotive flexible PCB technology.

All told

Capel’s 16 years of experience in automotive flexible PCB design, prototyping and manufacturing has crystallized into a tradition of excellence, innovation and proficiency. Their mastery of the complexity of the 8-layer HDI second-level rigid-flex PCB, precision material composition, advanced manufacturing processes and unwavering commitment to customer satisfaction have made them the unparalleled leader in automotive flexible PCB technology. As the automotive industry leaps into new frontiers of innovation, Capel’s expertise will continue to be a reliable foundation for future technological advancements.

Post time: Mar-04-2024

Back