Introduce:

In the ever-evolving world of technology, especially in the audio industry, the demand for innovative and high-quality electronic products continues to grow. As demand continues to grow, the need for an efficient and effective prototyping process becomes critical. Today we will explore the possibilities of PCB board prototyping for audio applications and answer the burning question: Can I prototype a PCB board for an audio application? With 15 years of circuit board manufacturing experience, its own factory and a dedicated R&D team, Capel has all the answers you need.

Learn about PCB board prototyping:

Before delving into the world of PCB board prototyping for audio applications, it’s important to master the basics. PCB, or Printed Circuit Board, is an important part of any electronic device. It acts as a platform to connect and support various electronic components through conductive paths etched into a non-conductive substrate. Through this interconnected system, signals and power can flow, allowing devices to operate efficiently.

Prototyping, on the other hand, involves creating a preliminary model or working prototype of a desired product. It allows engineers and developers to test and refine their designs before mass production. During the prototyping stage, it is critical to ensure that the PCB board meets the specific requirements of the audio application.

Audio Applications and PCB Board Prototyping:

The audio industry has made significant progress in recent years with the emergence of new technologies and the growing demand for high-quality sound reproduction. From music production and home audio systems to professional recording studios and portable equipment, audio applications vary widely in complexity and sophistication.

To meet these needs, PCB board prototyping plays a vital role. It enables engineers to design and develop PCB boards suitable for the specific requirements of audio applications. Whether it’s reducing noise interference, improving signal quality, or enhancing audio fidelity, prototyping allows for meticulous testing and refinement.

Capel: your ideal partner for PCB board prototyping:

Capel is a reliable and experienced partner when it comes to PCB board prototyping for audio applications. With 15 years of circuit board manufacturing experience, we have been at the forefront of providing best-in-class electronic solutions to various industries, including audio.

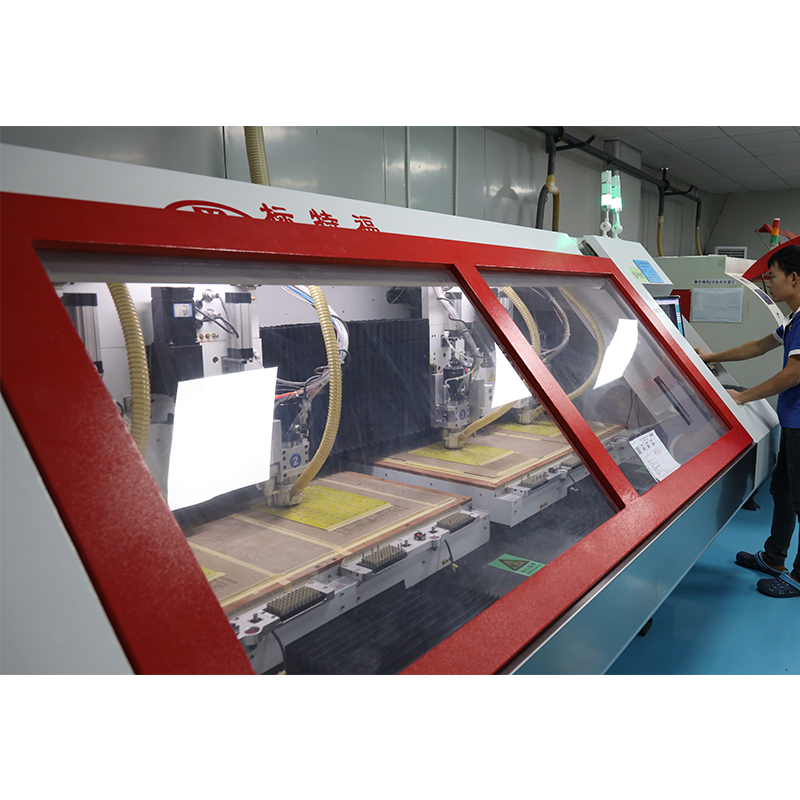

Our purpose-built factory houses state-of-the-art manufacturing facilities that enable us to produce PCB boards with exceptional precision and quality. In addition, our R&D team consists of highly skilled engineers who are passionate about innovation and committed to meeting the specific requirements of our customers.

Capel’s audio application PCB board prototyping method:

At Capel, we understand that every audio application has its unique needs and challenges. Therefore, we take a comprehensive, collaborative approach to PCB board prototyping. Here is a brief overview of our process:

1. Needs Analysis: We work closely with our clients to understand their specific needs and goals. Our team of experts analyze requirements and provide valuable insights to ensure the prototyping process achieves the desired results.

2. Design and Development: Our talented engineers utilize the latest design tools and techniques to create PCB layouts that meet the requirements of audio applications. We pay close attention to factors such as noise reduction, signal integrity and component placement to ensure optimal performance.

3. Testing and Refinement: Once the design phase is complete, our team will conduct thorough testing and evaluation. We use advanced testing equipment and methods to ensure prototypes meet required specifications. Customer feedback and suggestions are invaluable at this stage, allowing us to make necessary improvements and improvements.

4. Production and Delivery: Once the prototype is completed, our state-of-the-art manufacturing facility takes care of it. With advanced machinery and complete quality assurance processes, we guarantee the production of high-quality PCB boards that meet customer expectations. Additionally, we ensure timely delivery, minimizing any potential delays throughout the product development timeline.

In conclusion:

All in all, the answer to the question “Can I prototype a PCB board for an audio application?” is a resounding yes. With Capel’s expertise, experience and commitment to excellence, audio engineers and developers can confidently explore the possibilities offered by PCB board prototyping.

By understanding the unique needs of audio applications and following a comprehensive prototyping process, Capel ensures the final product meets the required specifications and sets a new benchmark for audio excellence.

So, if you are looking for a reliable partner to prototype your audio application PCB boards, feel free to contact Capel. With our 15 years of experience, in-house manufacturing facilities and dedicated R&D team, we have the ability to meet your needs and turn your audio innovations into reality.

Post time: Oct-18-2023

Back