Introduce:

Rapid PCB prototyping, especially the integration of fine-pitch components, requires expertise and precision. As technology continues to advance, circuit board manufacturing is becoming more complex and demanding. With over 15 years of experience in the field, Capel is a leading company that combines technical expertise and constant innovation to deliver unparalleled solutions. In this blog post, we’ll dive into the methods, challenges, and best practices for rapid PCB prototyping with fine-pitch components, while exploring Capel’s unparalleled manufacturing capabilities.

Learn about fine-pitch components:

Fine-pitch components play a vital role in modern electronic devices as they enable high-speed transmission, miniaturization, and improved functionality. The pin spacing of these components is less than 0.8 mm, which makes their precise placement on the PCB more challenging. Therefore, it is crucial to adopt specific techniques and methods to ensure successful prototyping.

Advanced PCB design tools for rapid prototyping:

In order to effectively utilize fine-pitch components for rapid PCB prototyping, advanced PCB design tools must be used. Software such as Altium Designer, Eagle or KiCad provide features such as precise component placement, signal integrity analysis and automatic routing functions, which greatly aid layout optimization. Capel’s team of experts are adept at leveraging these tools to ensure the highest level of accuracy during prototyping.

Things to note when laying out fine-pitch components:

When designing a PCB layout with fine-pitch components, it is critical to consider certain factors to ensure optimal functionality and manufacturability. Here are some important considerations:

1. Pad design: Pad size and shape are important considerations for proper soldering and good electrical contact with the component. Capel’s experienced engineers carefully design pads based on the specific requirements of fine-pitch components, providing excellent solderability and reliability.

2. Traces and vias: High-speed signals passing through fine-pitch components require careful routing to minimize noise, signal attenuation, and impedance mismatch. Proper via placement and trace routing techniques such as length matching and differential pair routing help maintain signal integrity.

3. Thermal management: Fine-pitch components generate a lot of heat during operation. Adequate thermal management through the use of heat sinks, thermal vents, or placing thermal pads beneath components is critical to preventing overheating and ensuring long-term reliability.

4. Design for Manufacturing (DFM): Work with Capel’s experienced team during the PCB design phase to ensure design choices are consistent with their manufacturing capabilities. Optimizing designs for manufacturability helps reduce prototyping errors and improves the overall efficiency of the process.

Prototyping challenges and solutions:

Rapid PCB prototyping with fine-pitch components presents special challenges. However, with Capel’s extensive experience and practical expertise, these challenges can be easily mitigated.

1. Component sourcing: Fine-pitch components often have long lead times or limited availability, making their sourcing more challenging. Capel’s extensive supplier network and strong relationships ensure timely access to high-quality components, ensuring uninterrupted production.

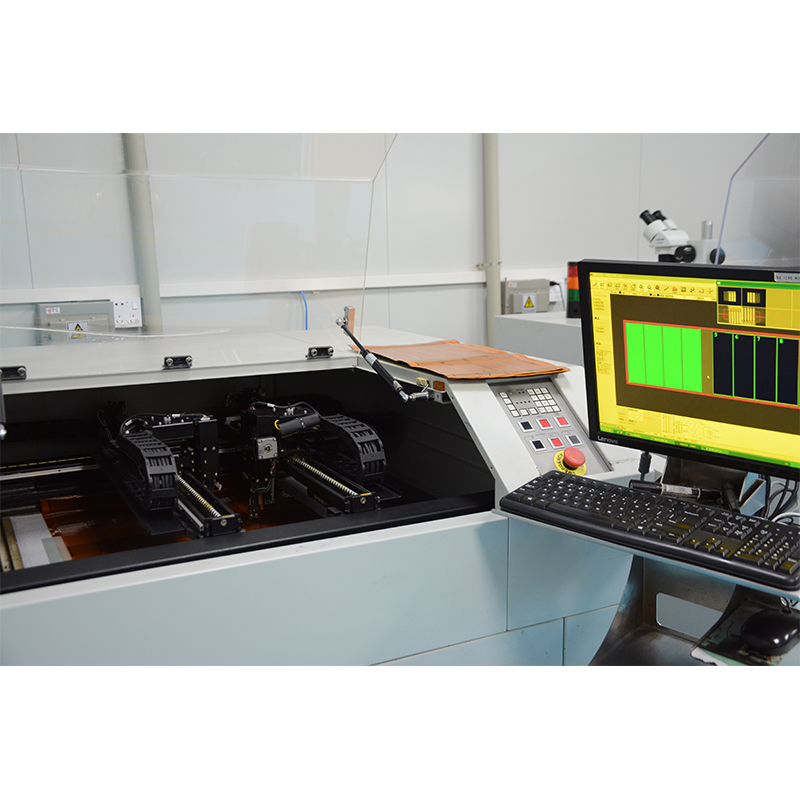

2. Welding: Welding fine pitch components requires high precision. Capel uses advanced assembly technologies such as reflow ovens with controlled temperature profiles, automated placement machines and solder paste inspection to ensure perfect solder joints.

3. Testing and Inspection: During the prototyping phase, thorough testing and inspection is critical to identify potential defects such as solder bridges, opens, or tombstones. Capel performs rigorous quality checks using automated optical inspection (AOI), X-ray inspection and boundary scan testing to ensure prototypes are flawless.

Capel’s unparalleled manufacturing capabilities:

Capel’s commitment to superior quality and continuous technological advancement has made it a trusted partner in the PCB manufacturing industry. The company’s vast expertise, complemented by state-of-the-art production facilities and adherence to international quality standards, enables it to offer unparalleled manufacturing capabilities.

In conclusion:

Rapid prototyping of PCBs using fine-pitch components requires specialized knowledge and skills. With 15 years of experience, expertise and commitment to continuous innovation, Capel is uniquely positioned to meet these challenges and exceed expectations. Working with Capel ensures flawless prototypes, efficient manufacturing processes and unparalleled support at every stage of the project. Trust Capel’s experts to bring your PCB prototype to life while meeting the most demanding requirements of the modern electronics industry.

Post time: Oct-18-2023

Back