In today’s fast-paced automotive industry, maintaining a competitive edge is critical. The company continuously strives to develop cutting-edge technologies that push the boundaries of innovation and drive the industry forward. A key element in achieving these goals is the development and prototyping of printed circuit boards (PCBs) specifically designed for automotive applications.

But can you prototype a PCB for automotive applications? The answer is yes! At Capel, we have the expertise and experience to help you achieve this.

Capel is a circuit board manufacturer with a 15-year history in the industry. Our technical expertise combined with an exceptional team of experts enables us to provide our customers with the highest quality PCB solutions tailored specifically for automotive applications. Our commitment to advanced process technology and superior process capabilities makes us a trusted partner to the automotive industry.

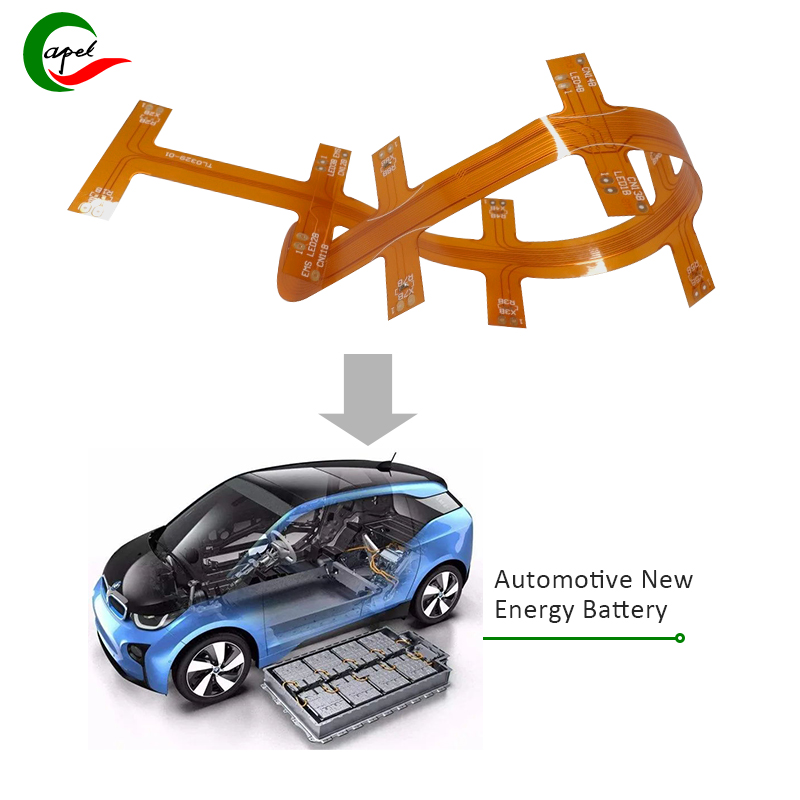

At Capel, we understand that the automotive industry requires the highest precision, reliability and durability from PCBs. As automotive technology becomes more advanced, PCBs play a vital role in various automotive systems, such as engine control units, infotainment systems, and autonomous driving technology. We are proud to help our customers meet the challenges of developing PCBs for these complex applications.

Our advanced automation equipment ensures that our PCB manufacturing processes meet the highest industry standards. This, combined with our comprehensive technical after-sales service, guarantees our customers fast response and effective support throughout their projects. We value our customers’ success and are committed to providing professional and reliable solutions that enable them to quickly seize market opportunities.

Over 15 years in the automotive industry, Capel has successfully solved many project problems for our clients. Our experience ranges from working with established car manufacturers to assisting start-up companies in turning their breakthrough ideas into reality. We approach every project with the same dedication and commitment to excellence, regardless of its scope or complexity.

The key to successfully prototyping PCBs for automotive applications is thorough research and design. The automotive industry has unique requirements such as resistance to high temperatures and vibrations, electromagnetic interference shielding, and strict safety regulations. Our team of experts work closely with customers to understand their specific needs and design PCBs that meet and exceed those requirements.

When prototyping PCBs for automotive applications, it is important to pay close attention to material selection. At Capel we only use the highest quality materials that are best suited to the needs of the automotive industry. Our experts carefully select substrates, copper foil and other components to ensure optimal performance, reliability and longevity.

Furthermore, we understand the importance of efficient time-to-market in the automotive industry. Our streamlined processes and expertise enable us to deliver high-quality PCB prototypes within tight timelines. We work closely with our clients to develop clear project timelines and follow strict project management practices to ensure timely delivery.

In conclusion, in today’s highly competitive automotive market, prototyping PCBs for automotive applications is not only possible, but also very necessary. Capel’s 15 years of technical expertise, coupled with our team of experts, advanced process technology and superior process capabilities, make us the ideal partner for all your PCB needs in the automotive industry. Our advanced automation equipment and complete technical after-sales services ensure fast response times and reliable solutions, allowing you to quickly seize market opportunities.

So, can you prototype a PCB for automotive applications? Yes, with Capel by your side, of course you can. Contact us today to learn more about our services and how we can help turn your automotive project into a reality.

Post time: Oct-14-2023

Back