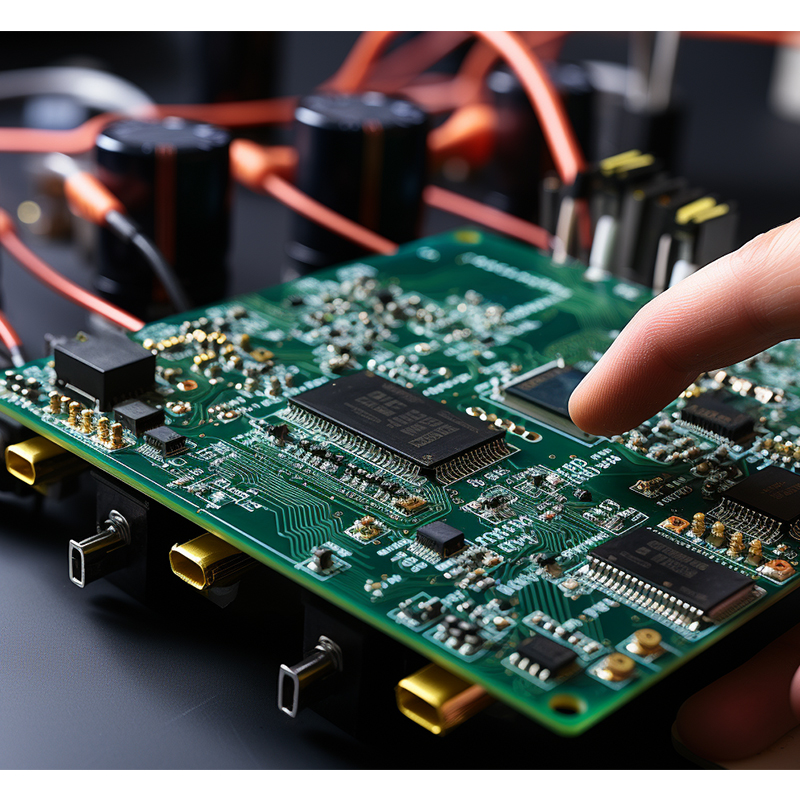

In this blog post, we will discuss the importance of protecting fast-turnaround PCB prototypes from ESD damage and provide some effective strategies to help you prevent this situation.

For the circuit board industry, one of the biggest challenges engineers face is protecting their fast-turn PCB prototypes from electrostatic discharge (ESD) damage. ESD is the sudden flow of electrical current between two objects with different electrical potentials and can be extremely harmful to sensitive electronic components.

Capel has a professional technical R&D team and 15 years of experience in the circuit board industry, and understands the importance of protecting your precious prototypes. With a strict quality control system, extensive circuit board project experience, and comprehensive pre-sales and after-sales technical services, Capel is the perfect partner to help you solve ESD problems and ensure that your fast-turnaround PCB prototypes are well protected.

Why is it important to protect your fast-turn PCB prototypes from ESD damage?

ESD damage can have serious consequences on fast-turnaround PCB prototypes. It can lead to electronic component failure, increased production costs, delayed project timelines, and ultimately lost revenue. Sensitive components such as microcontrollers, integrated circuits, and transistors can easily be damaged or destroyed by even a minor electrostatic discharge. Therefore, taking proactive steps to prevent ESD damage is critical to saving you time, effort, and resources.

Effective Strategies for Protecting Rapid Turnaround PCB Prototypes

1. Proper Grounding and ESD Defense: Implementing proper grounding techniques is critical to eliminating static electricity. Make sure your work area, tools and personnel are properly grounded. Use grounded workstations, conductive floors, and wrist straps to minimize charge build-up. Consider investing in ESD safe storage solutions such as static protection bags and conductive foam to protect your rapid turnaround PCB prototypes during shipping and storage.

2. ESD Awareness and Training: Educating your team on ESD risks and prevention techniques is critical. Conduct regular training sessions for employees to increase ESD awareness and emphasize the importance of safe handling practices. This will help minimize human error and reduce the likelihood of accidental ESD damage to quick turnaround PCB prototypes.

3. Controlled environment: Creating a controlled environment is critical to protecting fast-turnaround PCB prototypes. Maintain proper humidity to prevent static electricity build-up. Use an ionizer or anti-static mat to neutralize static charges. Designate designated ESD protected areas for assembly, testing, and storage of rapid turnaround PCB prototypes.

4. ESD Testing and Certification: Consider subjecting your flash PCB prototype to an ESD testing program to ensure its reliability and durability. Certified ESD testing laboratories can perform various tests, such as Human Body Model (HBM) and Charged Device Model (CDM) testing, to evaluate prototype performance under different ESD scenarios. This will help you identify potential weaknesses and implement necessary design modifications to increase ESD resilience.

5. Partner with Capel’s expertise: As a leader in the circuit board industry, Capel has the experience and expertise necessary to help you protect your fast-turnaround PCB prototypes from ESD damage. With extensive experience in circuit board projects and comprehensive technical services, Capel can provide valuable guidance and advice to improve the ESD resiliency of your designs. Their expert technical R&D team can work closely with you to understand your specific requirements and provide tailored solutions to reduce ESD risks.

In summary

Protecting your rapid turnaround PCB prototypes from ESD damage should be your top priority to ensure project success. By implementing the above strategies and working with Capel, you can significantly reduce the risk of ESD-related failures, save costs, and ensure your prototypes are delivered to the market with the highest possible quality and reliability. Don’t let ESD damage hinder your progress; take the necessary steps to protect your rapid turnaround PCB prototypes and set yourself up for success.

Post time: Oct-15-2023

Back