Discover the world of 4-layer FPC (Flexible Printed Circuit) prototyping and manufacturing with Capel, a leader in the field with over 16 years of experience. Discover the benefits, applications and advanced features of 4-layer FPC and learn about Capel’s role in delivering high quality , expertise in custom flexible PCB solutions.

1. Introduction to Capel 4-layer FPC

A. 4-layer FPC description

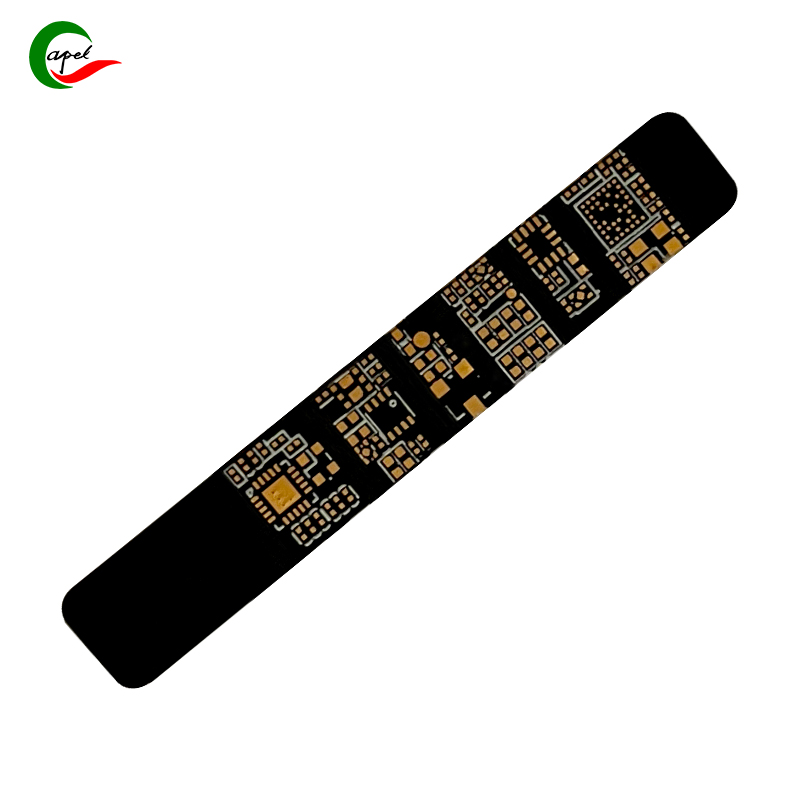

Capel’s 4-layer FPC (Flexible Printed Circuit) is a special type of flexible PCB that provides enhanced functionality and versatility for a variety of electronic applications. With its unique design and construction, 4-layer FPC delivers superior performance in demanding environments where flexibility and reliability are critical.

B. The Importance of Flexible PCB Prototyping and Manufacturing

Flexible PCB prototyping and manufacturing play a vital role in the development and production of advanced electronic devices. As the demand for compact, lightweight and high-performance electronics continues to grow, the need for reliable, efficient flexible PCB solutions is becoming increasingly important.

C. Overview of Capel’s expertise in the field

With over 16 years of expertise in 4-layer FPC prototyping and manufacturing, Capel has become a leading supplier of innovative and high-quality flexible PCB solutions. Our commitment to precision, quality and customer satisfaction has earned us a reputation for industry excellence.

2. Understand 4-layer FPC: advantages and applications

A. Definition and characteristics of 4-layer FPC

A 4-layer FPC consists of four conductive layers separated by an insulating layer, all of which are designed to be flexible. This structure increases routing density, improves signal integrity, and enhances thermal management, making 4-layer FPC ideal for complex electronic designs.

B. Advantages and applications of 4-layer FPC

The advantages of 4-layer FPC include reduced size and weight, improved reliability, and enhanced flexibility, making it suitable for a wide range of applications including aerospace, medical devices, automotive electronics, and consumer electronics.

C. Comparison with other types of PCB

Compared to traditional rigid PCBs and other types of flexible PCBs, 4-layer FPC offers superior performance in terms of space utilization, signal integrity, and mechanical flexibility, making it the first choice for many advanced electronic designs.

3. 4 Layer Flexible PCB prototyping process: accuracy and quality

A. Step-by-step guide to flexible PCB prototyping

The flexible PCB prototyping process involves several key steps, including design verification, material selection, artwork generation, imaging, etching, drilling, and final inspection. Each step requires precision and attention to detail to ensure the quality and reliability of the prototype.

B. The Importance of Accuracy and Quality in Prototyping

Precision and quality are critical in flexible PCB prototyping to ensure the final product meets design requirements and performance specifications. Capel’s rigorous prototyping process is designed to deliver prototypes that meet the highest standards of quality and reliability.

C. Capel’s Flexible PCB Prototyping Method

Capel uses advanced prototyping technology and state-of-the-art equipment to ensure the accuracy and consistency of our flexible PCB prototypes. Our experienced team of engineers and technicians work closely with customers to optimize designs and resolve any potential issues early in the prototyping process.

4. Manufacturing of 4-layer FPC: Advanced Manufacturing Technology

A. 4-Layer FPC manufacturing detailed process

The manufacturing process of 4-layer FPC involves multiple stages, including material preparation, lamination, imaging, etching, plating, solder mask application, surface treatment and final inspection. Each stage is critical to the overall quality and performance of the finished product.

B. Quality control measures in FPC manufacturing

Quality control is a top priority in 4-layer FPC manufacturing, with strict measures taken to ensure the consistency and reliability of the finished product. Capel’s manufacturing facility is equipped with advanced testing and inspection equipment to verify the quality of each FPC.

C. Capel’s advanced manufacturing capabilities

Capel’s manufacturing capabilities include advanced equipment and processes for producing high-quality 4-layer FPCs with tight tolerances and complex designs. Our commitment to continuous improvement and innovation enables us to meet our customers’ ever-changing needs with cutting-edge manufacturing solutions.

5. Benefits of choosing Capel for 4-layer FPC

A. Expertise and experience in flexible PCB manufacturing

With over 16 years of experience, Capel has a deep understanding of the unique challenges and requirements of flexible PCB manufacturing. Our expertise allows us to provide innovative solutions that meet the most demanding specifications.

B. Customization and design flexibility provided by Capel

Capel offers a high degree of customization and design flexibility to meet customers’ specific needs. Whether it is a complex multi-layer FPC or a custom-shaped flex circuit, our team can provide tailor-made solutions to meet different design requirements.

C. Testimonials and Success Stories from Capel Customers

Our track record of success is reflected in the testimonials and success stories of our satisfied customers. Capel has earned the trust and loyalty of customers across industries by consistently delivering high-quality 4-layer FPC and exceeding customer expectations.

4 Layer Flex PCB Prototype and Fabrication

6. Conclusion and call to action

A. Review the importance of 4-layer FPC and flexible PCB manufacturing

The importance of 4-layer FPC and flexible PCB manufacturing cannot be overstated as these technologies help develop advanced electronic devices with improved performance and reliability. Capel’s expertise and capabilities make us a trusted partner for businesses looking for reliable FPC solutions.

B. A call to action for companies looking for reliable FPC solutions

For businesses looking for reliable FPC solutions, Capel offers comprehensive services from prototyping to high-volume manufacturing. Our commitment to quality, precision and customer satisfaction makes us the ideal partner for companies seeking to leverage the benefits of flexible PCB technology.

C. Contact Information for Capel Services

To learn more about Capel’s 4-layer FPC prototyping and manufacturing capabilities, please contact us at [E-mail xgkbe@kbefpc.com ]. Our team of experts are ready to help you with your flexible PCB needs and provide tailor-made solutions to support your electronic design projects.

Post time: Mar-11-2024

Back