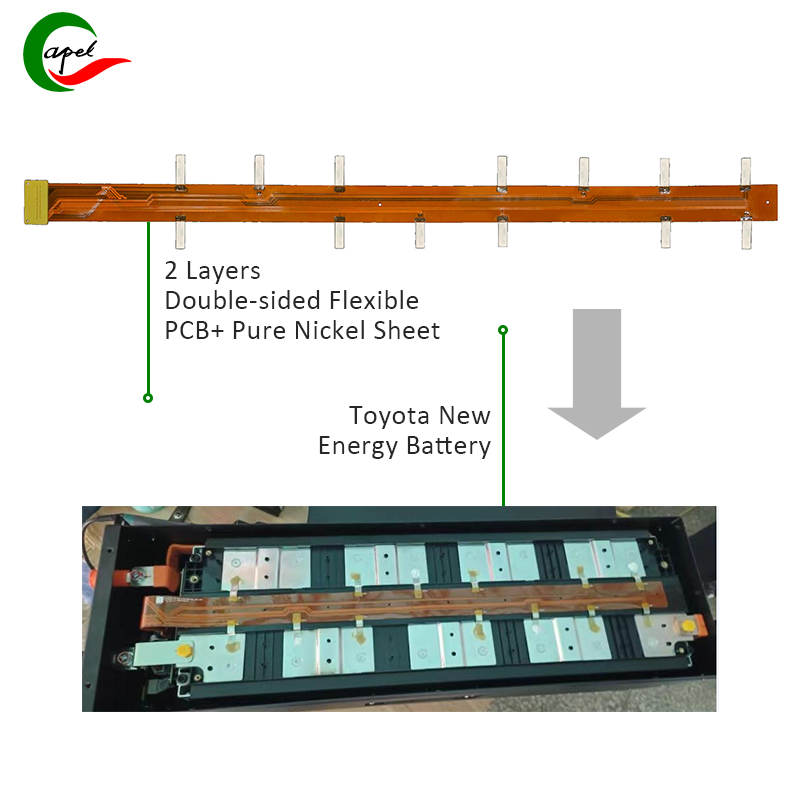

In recent years, the application of new energy battery technology has advanced by leaps and bounds, and more and more companies have invested in research and development to maintain their leading position. A key component of this technology is the double-sided flexible PCB board, which is enhanced by the addition of pure nickel sheets. In order to help everyone better understand this innovative technology, we will discuss how the combination of Shenzhen Capel Technology Co., Ltd.’s 2-layer double-sided flexible circuit board and pure nickel sheet can bring breakthrough innovation to new energy battery technology.

First of all, let’s briefly understand the role of 2-layer double-sided FPC PCB and pure nickel sheet in new energy batteries:

A 2-layer double-sided FPC PCB+pure nickel sheet is a multi-functional high-performance product designed for new energy battery applications. Its main feature is flexibility since it is a double-sided flexible printed circuit board (FPC). This means it can be easily bent and shaped to fit the dimensions and specifications required for battery applications. The 2-layer design of the PCB ensures optimum performance and functionality. Each layer of the PCB contains electronic components and traces that enable the efficient transmission of electrical signals and power within the battery system. The double-sided structure also provides more space and capacity to accommodate various components and functions.

The role of pure nickel sheets in new energy batteries: Due to their excellent properties, nickel occupies an important place in the field of battery technology. As the positive electrode of new energy batteries, pure nickel sheet has excellent electrical conductivity, corrosion resistance, and thermal stability. By combining pure nickel with other elements, battery manufacturers can optimize the battery’s performance, increasing its energy density and overall lifetime. Pure nickel sheets help improve the efficiency and safety of new energy batteries by promoting stable electrochemical reactions.

Below, we will analyze how the combination of Capel 2-layer flexible circuit boards and pure nickel sheets can bring

technological innovation to the new energy battery industry based on visualized product data.

It can be known from the product attributes, that the line width and line spacing values in the PCB design are 0.15mm and 0.1mm, respectively, indicating that the traces or conductive paths on the board are narrow enough and closely spaced. This precision helps ensure the accurate transmission of signals within the new energy battery system, minimizing any potential signal corruption or interference. The board thickness consists of a 0.15 mm thin flexible printed circuit (FPC) layer and a 1.6 mm thick base layer. This combination of layers provides a balance of durability and stability to the PCB. The FPC layer is thin and flexible, allowing the board to be bent or shaped as needed, while the thicker base layer adds strength and rigidity to the overall structure of the PCB. Copper Thickness, specified as 1 oz, refers to the amount of copper coating on the conductive traces of the PCB. 1oz copper thickness is a common standard and provides high conductivity. The copper coating ensures low resistance and efficient transmission of electrical signals, helping to improve the overall performance and reliability of the PCB.

In PCB manufacturing, film thickness is really critical to provide insulation and protection for electronic components. In this particular product, the film thickness is specified at 50μm (micrometers), which ensures adequate insulation between conductive traces and prevents short circuits or signal interference. Also, the surface finish of choice for this PCB is ENIG (Electroless Nickel Immersion Gold) with a thickness of 2-3μin (micro inches). ENIG is a popular surface treatment in PCB manufacturing due to its excellent corrosion resistance and flatness. The nickel layer provides an anti-oxidation barrier, ensuring long-term durability, while the gold layer provides a reliable contact surface for electrical connections. The combination of 50μm film thickness and ENIG surface treatment helps to improve the insulation, protection, durability and overall quality of circuit boards, making them suitable for reliable operation of electronic equipment.

The 658*41MM size 2-layer double-sided FPC PCB+pure nickel sheet enables versatility and integration into various systems and devices including vehicles. The compact size allows the PCB to fit in space-constrained applications while providing the necessary functionality. In automotive applications, this size is advantageous because it can be easily integrated into the vehicle’s electrical system. PCBs are used for a variety of purposes, such as controlling lights, sensors, power distribution, and other electronic functions in a car. The double-sided design of FPC PCB can increase circuit density and accommodate more components and circuits in a smaller area. This feature is especially useful when designing PCBs for vehicles where space is often limited. In addition, pure nickel sheets used in conjunction with FPC PCBs have additional advantages. Nickel is known for its excellent electrical conductivity and corrosion resistance. It ensures reliable current flow and protects against environmental factors, making it suitable for automotive applications where vibration, heat and humidity may be encountered. Overall, the size and characteristics of the 2-layer double-sided FPC PCB + pure nickel board make it a versatile and reliable choice for integration into various systems and devices including vehicles.

Now, let’s dig into what makes this product unique, which is the use of pure nickel sheets. The use of pure nickel plate in this

product offers several unique advantages.

First, a 0.3 mm thick nickel sheet provides the best electrical conductivity. Nickel is known for its low current resistance, which ensures the efficient transfer of electricity within the battery system. This characteristic is critical in new energy battery applications, where a smooth flow of electricity is critical for optimal performance.

Second, a 100 μm thick PI (polyimide) film was coated on the nickel sheet. The film acts as a protective layer, enhancing corrosion resistance. Corrosion can be a significant problem in battery applications, especially when exposed to harsh environments or chemicals. The PI film effectively protects the nickel sheet from corrosion, thereby prolonging the life of the battery and maintaining its performance for a long time.

In addition, nickel flakes can be used as effective current collectors. In battery systems, current collectors are responsible for collecting and distributing current throughout the battery cell.Using a pure nickel sheet as the current collector ensures minimal resistance, allowing efficient and uninterrupted current flow. This improves the overall performance and efficiency of the battery system.

In terms of functional testing, the 2-layer double-sided FPC PCB + pure nickel sheet has undergone a series of evaluations to

ensure its reliability and adherence to high-quality standards.Tests such as AOI (Automated Optical Inspection), four-wire

testing, continuity testing and copper strip evaluation ensure products meet the highest quality standards.

Automated Optical Inspection (AOI) is a visual inspection technique that uses cameras and image processing algorithms to detect any manufacturing defects on a PCB. This includes checking for missing components, incorrect placement and soldering issues. AOI helps identify any potential issues that could affect PCB functionality and reliability.

Four-wire testing is an electrical testing method that measures voltage and current with high precision. It helps to verify the integrity and accuracy of the electrical connections on the PCB. By measuring resistance, this test ensures that all required electrical connections are properly made and functioning as expected.

Continuity testing is another important evaluation process. It checks for proper electrical connections between the various components and circuit traces on the PCB. This test helps to identify any opens, shorts, or other electrical problems that may affect the function of the PCB.

Copper tape evaluation focuses specifically on the integrity and quality of the copper tape used in the PCB. It ensures that the copper tape is the correct size, adequately bonded to the PCB surface, and free of any defects. This evaluation guarantees that the copper strip can handle the required current without any problems.

By doing these tests, you can have full confidence in the reliability and quality of the 2-layer double-sided FPC PCB + pure nickel sheet. These evaluations provide valuable insight into a product’s functionality and performance, ensuring it meets the highest quality standards and can be used with confidence in a variety of applications.

One of the notable applications of this product is in the automotive industry, especially in vehicles such as Toyota. With the increasing demand for electric and hybrid vehicles, 2-layer double-sided FPC PCB + pure nickel sheets play a vital role in the function of new energy batteries. By providing efficient power distribution and protection from external elements, this product contributes to the smooth operation and longevity of battery systems.

From the above analysis, it can be seen that the combination of the double-sided flexible PCB board of Shenzhen Capel Technology Co., Ltd. and the pure nickel sheet has brought many benefits and applications to the new energy battery industry. Its flexibility, precise specifications, and addition of nickel contribute to performance, durability, and safety. This product is an essential part of the quest for sustainable and environmentally friendly energy solutions. With 15 years of rich project experience, rigorous process flow, excellent process capability, advanced automation equipment, perfect quality control system, and a professional expert team, Capel provides global customers with high-precision, high-quality fast circuit boards, including Flexible pcb boards, rigid circuit boards, rigid-flex pcb boards, HDI boards, high-frequency pcb, special craft boards, etc., quick response pre-sales, after-sales technical services and timely delivery services enable our customers to quickly seize the market chance for their projects.

Post time: Aug-24-2023

Back