Flexible PCB Introduction: Overview of Technology and Industry Challenges

Flexible printed circuit boards (Flex PCBs) have revolutionized the electronics industry by providing high-density interconnections in lightweight, flexible packages. As an engineer with 15 years of experience in the flexible circuit board industry, I understand the challenges and opportunities that flexible PCBs present. In this article, we will delve into various aspects of flexible PCB design and prototyping to provide practical solutions and insights for customers looking to address the complexities of flexible PCB technology.

Understanding the Importance of Flexible PCBs:The Versatility and Impact of Flexible PCBs in Modern Applications

Flexible PCBs have been widely adopted in applications such as consumer electronics and medical devices, aerospace and automotive industries. Their flexibility, lightweight and high-density interconnect capabilities make them ideal for products requiring compact, durable and reliable circuits. As a result, the need for high-quality flexible PCB design and prototyping has never been greater.

Flexible PCB design challenges address the complexities of material selection, design flexibility, and signal integrity

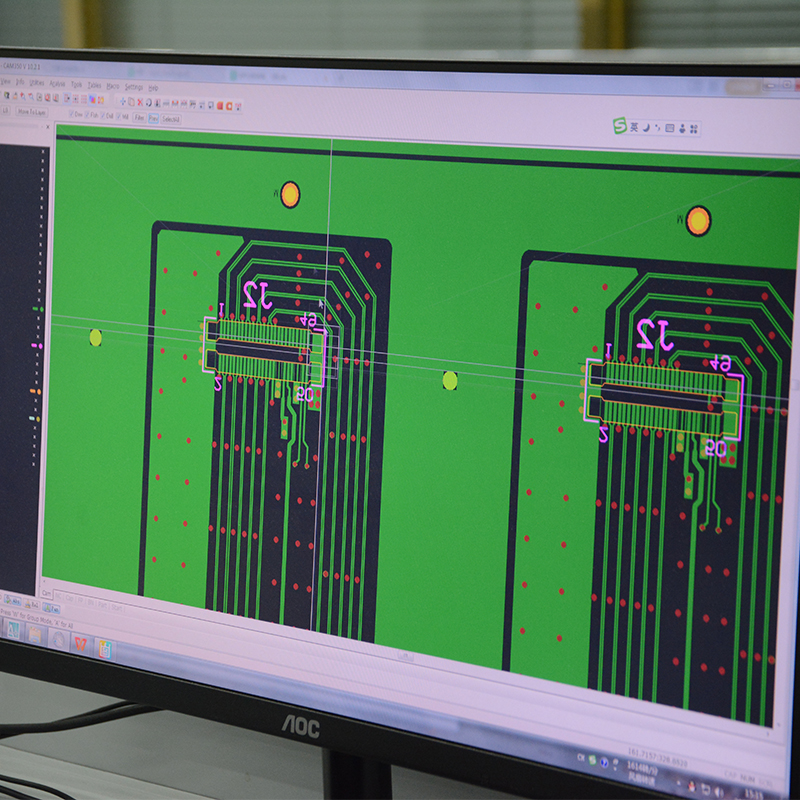

Designing a successful flexible PCB requires addressing numerous challenges, including material selection, design flexibility, and ensuring signal integrity. At our company, we have honed our expertise in meeting these challenges by combining advanced design tools, deep materials knowledge, and a focus on performance-driven design principles.

Key Material Selection Considerations and In-depth Knowledge for Best Flexible PCB Materials

Material selection is critical in flexible circuit board design because it directly affects flexibility, thermal performance, and signal integrity. Our team has extensive experience in evaluating and selecting the right materials for specific application requirements. From polyimide-based substrates to flexible adhesive systems, we ensure the materials selected meet the required performance characteristics while meeting cost considerations.

Flexible design integrating advanced tools and methods to ensure reliability under rigid conditions

Flexible PCBs are designed to withstand repeated bending and flexing without affecting electrical performance. Achieving this requires a deep understanding of mechanical design principles and material behavior. By integrating finite element analysis (FEA) and advanced simulation tools into our design process, we can accurately predict how flexible PCBs will behave under various bending conditions, ensuring reliable performance under real-world conditions.

Signal integrity considerations meet high-speed design requirements and ensure seamless integration

Maintaining signal integrity in flexible PCBs can be challenging due to the dynamic nature of the circuits. Our approach includes rigorous signal integrity analysis, impedance control, and meticulous attention to high-speed design guidelines. By utilizing simulation tools and empirical testing, we ensure that our flexible PCB designs meet stringent signal integrity requirements for seamless integration into high-performance electronic systems.

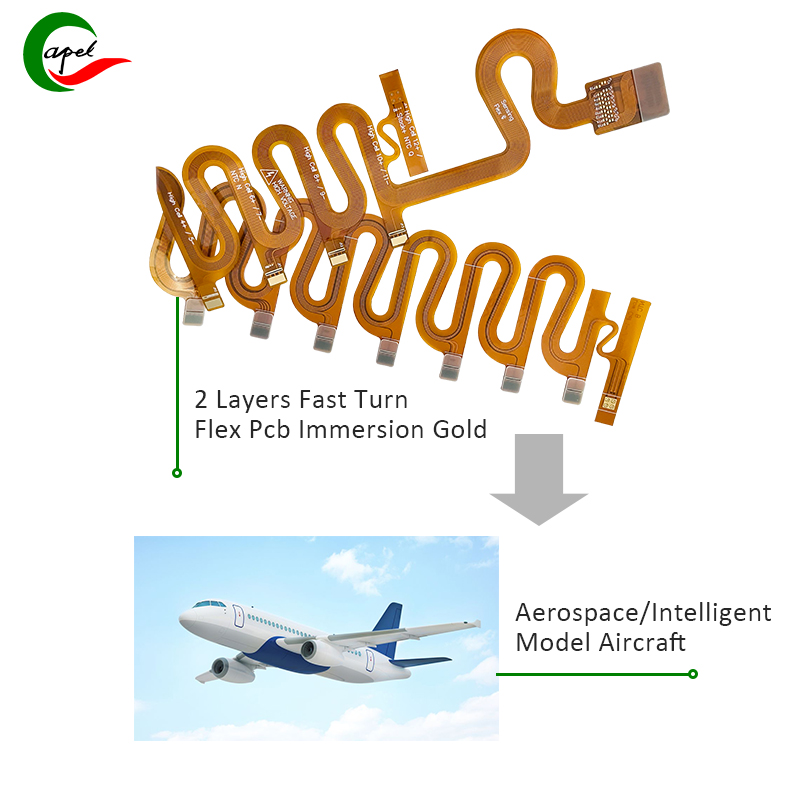

Classic Case Analysis Case Study: Aerospace Flexible PCB Solution

Classic Case Study:

To illustrate our expertise in flexible circuit board design and prototyping, let’s delve into a classic case study where our team successfully solved a unique challenge faced by a customer in the aerospace industry.

Aerospace Flexible PCB Solutions

Background: Our customer, a leading aerospace manufacturer, needed a reliable flexible PCB solution for next-generation avionics systems. This application requires a highly flexible, lightweight interconnect solution that can withstand extreme temperatures, vibration, and stringent EMI/RFI requirements.

Challenges: The aerospace environment presents unique challenges to electronic components, particularly in terms of reliability, weight reduction and thermal performance. Our team had to solve the following key challenges:

Design a flexible interconnect system that can withstand repeated bending and bending in confined spaces.

Ensure signal integrity and EMI/RFI compliance in high-frequency avionics environments.

Meet strict weight and space constraints without compromising performance.

Solution: Working closely with the customer’s engineering team, we developed a custom flexible PCB solution that met the specific requirements of the avionics system. Key elements of our solutions include:

Advanced material selection: We identified a high-performance polyimide-based substrate with excellent thermal stability and flexibility to meet the demanding requirements of aerospace environments.

Rigorous Mechanical Design: Using FEA and mechanical testing, we optimized the flexible PCB layout to ensure reliable performance under extreme bending conditions while minimizing weight and space usage.

Signal Integrity Verification: Using simulation tools and empirical testing, we confirm the integrity of high-speed signal paths, mitigating EMI/RFI issues and ensuring compliance with aerospace standards.

The result: a custom flex PCB solution that not only met but exceeded the customer’s expectations, providing a robust interconnect system that delivers superior performance in aerospace environments. The successful implementation of our flexible PCB solutions helps reduce weight, improve reliability and enhance system performance, making our company a trusted partner for aerospace electronics solutions.

Flexible PCB Prototype Process

Conclusion Utilizing cutting-edge flexible PCB technology to enhance engineering solutions

With the continuous advancement of technology and the increasing demand for compact, lightweight electronic systems, the role of flexible PCBs in modern engineering is undeniable. At our company, we are at the forefront of flexible PCB design and prototyping, providing tailor-made solutions to meet the specific needs of different industries. By prioritizing material selection, design flexibility and signal integrity considerations, we ensure our flexible PCB solutions deliver unparalleled performance and reliability in the most challenging environments.

As the industry continues to evolve, our commitment to innovation and excellence makes us the partner of choice for customers seeking cutting-edge flexible PCB solutions. Whether in aerospace, medical, automotive or consumer electronics, we are committed to pushing the boundaries of flexible PCB technology, giving our customers the confidence and success to achieve their engineering goals.

Post time: Jan-27-2024

Back