1. Introduction

Welcome to Capel’s world of 2-layer rigid-flex PCB prototyping and manufacturing, where innovation meets precision. With over 15 years of industry experience, Capel has become a leading provider of rigid-flexible PCB solutions. This article will delve into the benefits and applications of 2-layer rigid-flex PCBs, technical specifications, and why Capel is the first choice for PCB prototyping and manufacturing.

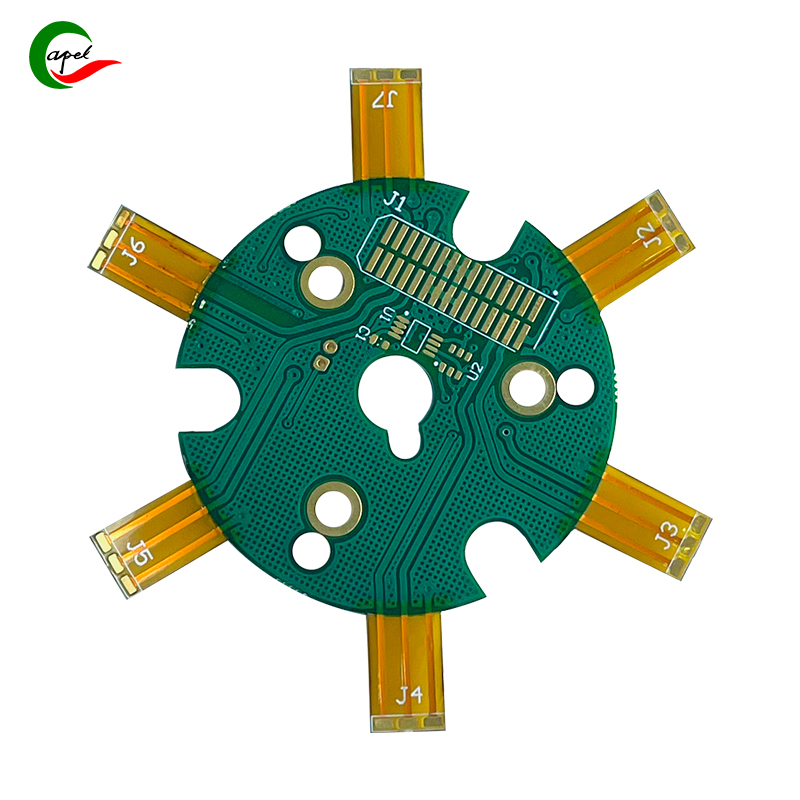

2. Product description

Capel’s 2-layer flexible rigid board is a versatile solution that can be used in medical equipment such as electrocardiogram (ECG) machines. Meticulously crafted, the technical specifications of Capel’s 2-layer rigid-flex board include line width and line spacing 0.15mm/0.15mm, board thickness 0.8mm+-10%, stacking 1+1, minimum aperture 0.2mm, copper hole thickness 35um, surface Process ENIG 2-3uin. These specifications ensure that PCBs meet high-quality industry standards and specific requirements for medical device applications.

3. Advantages of 2-layer rigid-flex board for prototyping and manufacturing

Capel’s 2-layer rigid-flex boards offer several advantages for prototyping and manufacturing:

Flexibility and durability: The flexible nature of rigid-flex PCBs allows for more complex designs and shapes, making them ideal for space-constrained applications such as medical equipment. Additionally, their durability ensures long-term performance, making them a reliable choice for a variety of applications.

Meet technical requirements: 2-layer rigid-flex laminates have precise technical specifications to meet the specific technical requirements of various applications, ensuring optimal performance and functionality.

Enhanced reliability and performance: 2-layer rigid-flex boards offer enhanced reliability and performance compared to traditional PCBs, making them the first choice for critical applications such as medical devices.

Cost-effective and time-saving advantages: Leveraging the advantages of rigid-flex PCBs, Capel’s solutions provide cost-effective and time-saving advantages during prototyping and manufacturing, ultimately enabling efficient product development.

4. Why choose Capel for 2-layer rigid-flex PCB prototyping and manufacturing

Capel is the preferred partner for 2-layer rigid-flex PCB prototyping and manufacturing for several key reasons:

Industry Experience: With 15 years of industry experience, Capel has honed its expertise and gained valuable insights in producing high-quality rigid-flex boards, making it a trusted name in the industry.

Expertise and Advanced Capabilities: Capel’s advanced capabilities, state-of-the-art facilities and skilled professionals ensure the production of high-quality, reliable PCB solutions that meet the stringent requirements of the medical industry.

Customer Testimonials and Success Stories: Capel’s track record is filled with success stories and positive customer testimonials, demonstrating their commitment to providing superior PCB solutions and exceptional customer service.

2 Layer Rigid Flexible PCB Prototyping And Manufacturing

5 Conclusion

In summary, 2-layer rigid-flex boards offer unparalleled advantages for prototyping and manufacturing, especially in critical applications such as medical devices. Capel’s expertise, precision and dedication to quality make them the ideal choice for your PCB prototyping and manufacturing needs. We encourage you to choose Capel for innovative, reliable and high-performance PCB solutions that meet and exceed industry standards to ensure your project is a success.

When it comes to 2-layer rigid-flex PCBs for prototyping and manufacturing, Capel is your trusted partner for excellence.

Post time: Jan-27-2024

Back