Flying probe testing of circuit boards is a critical testing step in the electronics manufacturing process and is designed to verify the electrical continuity and connectivity of electronic circuit boards. This test tests a circuit board by touching a specific point on the board with a small pointed metal probe, called a flying probe. The following is a technical report on the flying probe test of the circuit board, with detailed content and in-depth analysis.

Circuit board flying probe testing technology and application

Abstract: Flying probe testing of circuit boards is an integral part of the electronics manufacturing process. It verifies the board’s critical connection points and connectivity. This article will conduct an in-depth discussion on the principles, processes, applications, and future development trends of flying probe testing of circuit boards.

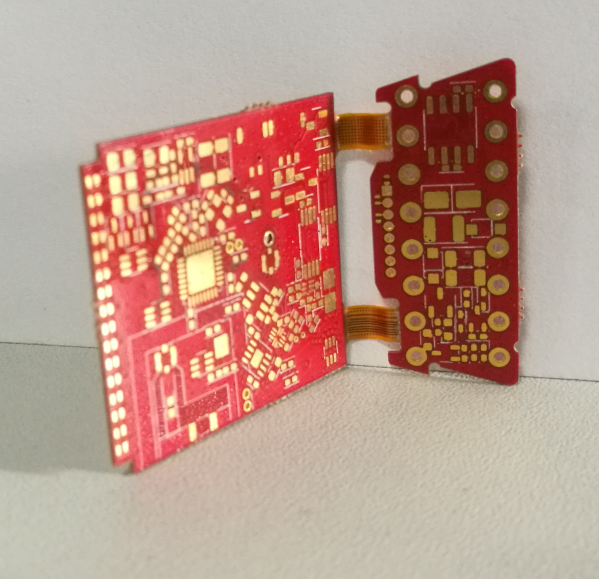

flying probe testing technology for rigid flex pcb and flexible pcb

Circuit board flying probe test principle

Flying probe testing uses a vertically moving probe to touch electrical connection points on a circuit board to verify continuity or break connections.

Test equipment includes flying probe test machines, test program controllers and adapters, etc.

Circuit board flying probe test process

Early preparation: determine test points, establish test point coordinate mapping, and set test parameters.

Test execution: The test program controller starts the flying probe test machine to test according to the preset test point sequence.

Test result analysis: automatically analyze test results, record test data, and generate test reports.

Circuit board flying probe test application

Flying probe testing of circuit boards is often used for mass-produced electronic products to ensure product quality and performance stability.

In electronic manufacturing factories, flying probe testing is widely used in PCB assembly, electrical connection testing, etc.

Future development trends of circuit board flying probe testing

Automation trend: Flying probe test equipment will become more intelligent, realizing automatic identification of test points and intelligent generation of test programs.

High-speed, high-precision trend: With the development of electronic products, flying probe testing equipment will pay more attention to testing speed and accuracy.

Flying probe testing of circuit boards plays a key role in the electronics production process

Fault Detection: Flying probe testing can help detect electrical connection issues on a circuit board, such as shorts, opens, and incorrect connections. By detecting these faults, you can ensure that the quality of produced circuit boards meets standards.

Verify the design: Flying probe testing can verify the correctness of the circuit board design, including circuit layout, component location, and wiring connections. This helps ensure the board meets design specifications and identifies potential design issues ahead of time.

Production efficiency: Through flying probe testing, connection problems on the circuit board can be quickly and automatically detected, thereby improving production efficiency. It can eliminate faults in the production process in time and reduce the production line stagnation time.

Quality Assurance: Flying probe testing helps ensure consistent quality on every circuit board. It can conduct consistency testing on mass-produced circuit boards to reduce the occurrence of defective products and improve the overall quality level.

Customer Satisfaction: Flying probe testing increases customer satisfaction by ensuring products meet specifications and customer requirements. By detecting quality issues and resolving them promptly, customer complaints and returns can be avoided.

Failure analysis: Flying probe testing can help conduct an in-depth analysis of failures and find out the cause of the problem. This helps improve design and production processes to avoid similar problems from happening again.

Data recording and tracking: Flying probe testing systems typically record test results and data, which can be used to track and analyze product quality trends. This helps to continuously improve production processes and improve product quality.

Flying probe testing of circuit boards is very important for quality control of flexible circuit boards and rigid-flex circuit

boards.

Quality control of flexible circuit boards: Due to their flexibility and thinness, flexible circuit boards are susceptible to deformation such as bending and torsion, so defects are prone to occur during the manufacturing process. Flying probe testing can detect connection problems caused by bending or deformation, ensuring the stability and reliability of electrical connections.

Quality control of hard and soft circuit boards: Hard and soft circuit boards are composed of rigid components and flexible components, and require reliable connection at the interface. Flying probe testing can ensure the connection stability of soft and hard combination circuit boards and avoid electrical problems caused by poor contact between soft and hard combinations.

Contact performance test: According to the characteristics of flexible circuit boards and soft-hard combination circuit boards, flying probe testing can detect their contact performance, including testing of sockets, connectors, solder joints, etc., to ensure their reliability and stability. connect.

Spring pressure test: For flexible circuit board connectors, flying probe testing can detect the pressure of the connection spring to ensure the stability and reliability of the number of plugs and pulls.

Flying probe testing of circuit boards plays a key role in meeting our customers’ high standards:

Quality Assurance: Flying probe testing can ensure that the electrical connection and connectivity of the circuit board meet the high standards required by customers, avoiding failures and adverse effects caused by connection problems.

Reliability verification: Through flying probe testing, the reliability and stability of the circuit board can be verified to ensure that it can still work normally in a high-standard usage environment and improve the reliability and stability of the product.

Defect screening: Flying probe testing can detect and eliminate defects in the circuit board manufacturing process early, ensuring that products meet high standards of quality requirements before being delivered to customers, and reducing failure rates and customer complaints.

Cost control: Flying probe testing can effectively control costs in the product manufacturing process. By discovering possible quality problems in advance and repairing them promptly, repeated manufacturing and additional costs caused by quality problems can be avoided.

In conclusion: Flying probe testing of circuit boards is a vital part of the electronic manufacturing field. It can effectively ensure the electrical connectivity and quality stability of electronic products. With the continuous improvement of automation and intelligent technology, circuit board flying probe testing will usher in broader development prospects.

We hope this article can help you gain a deeper understanding of circuit board flying probe testing.

Post time: Dec-19-2023

Back