Uncovering the benefits of HDI PCB prototype in modern manufacturing

In a hyper-connected world driven by state-of-the-art technology, high-density interconnect (HDI) PCB prototyping has become an indispensable element in printed circuit board (PCB) manufacturing. This article aims to explore all aspects of HDI PCB prototyping, from understanding its basic nature to revealing its advantages, design features, selection criteria for the right manufacturer, and tips for optimizing production.

1. What is HDI PCB prototype?

HDI PCB prototype is the abbreviation of High Density Interconnect PCB prototype, which is a special circuit board prototype that integrates advanced miniaturization and interconnection technology. It is designed to accommodate complex and compact electronic designs, meeting the needs of the ever-evolving electronics industry.

The importance of prototyping in PCB manufacturing cannot be overstated. It provides a test bed for new designs, allowing engineers to identify and correct potential problems before full production. HDI PCB prototypes act as a bridge between design and volume production, allowing for comprehensive testing of functionality, performance and reliability.

Using HDI technology in PCB prototyping offers a range of benefits. It enables complex designs to be integrated into a smaller footprint, reducing signal loss, enhancing performance and improving reliability.

2. Understand HDI PCB prototyping

HDI PCBs are known for their high circuit density and thin line technology. Features include microvias, blind and buried vias and sequential lamination. These properties allow them to accommodate more complex and miniaturized designs compared to traditional PCBs.

Different types of HDI technologies are available to meet specific design requirements. These include 1+N+1, 2+N+2 and stacked micropores, each with unique advantages. Advantages of using HDI in PCB prototyping include improved reliability, reduced signal interference and enhanced electrical performance.

3. Why choose HDI technology for PCB proofing?

The decision to use HDI technology in PCB prototypes was based on its ability to significantly enhance signal integrity and reliability. By minimizing signal loss and enhancing electrical performance, HDI technology has become imperative in applications requiring high-speed and high-frequency signals.

Additionally, HDI technology provides a cost-effective solution for PCB prototyping, reducing production time and material usage. It provides high-density interconnects that facilitate the integration of complex designs and paves the way for smaller, more efficient electronic devices.

4. How to choose the right HDI PCB prototype manufacturer

Selecting the most appropriate PCB manufacturer to produce HDI prototypes requires careful consideration of several factors. These factors include the manufacturer’s experience and expertise in HDI technology, the ability to provide a high-quality and reliable prototyping process, and compliance with industry standards and certifications.

A trustworthy manufacturer should have a proven track record of producing high-quality HDI PCB prototypes, and their expertise should match the specific design and technical requirements of the project. Quality assurance, compliance with design specifications and timely delivery are key in the selection process.

5. Tips for optimizing HDI PCB prototype production

Design considerations play a key role in optimizing HDI PCB prototype production. Careful attention to layout, layer stacking, and signal integrity is critical to ensuring a successful implementation of HDI technology. Comprehensive testing and validation of prototypes is critical to guarantee performance and reliability, while manufacturability and scalability should be integral components of the design process.

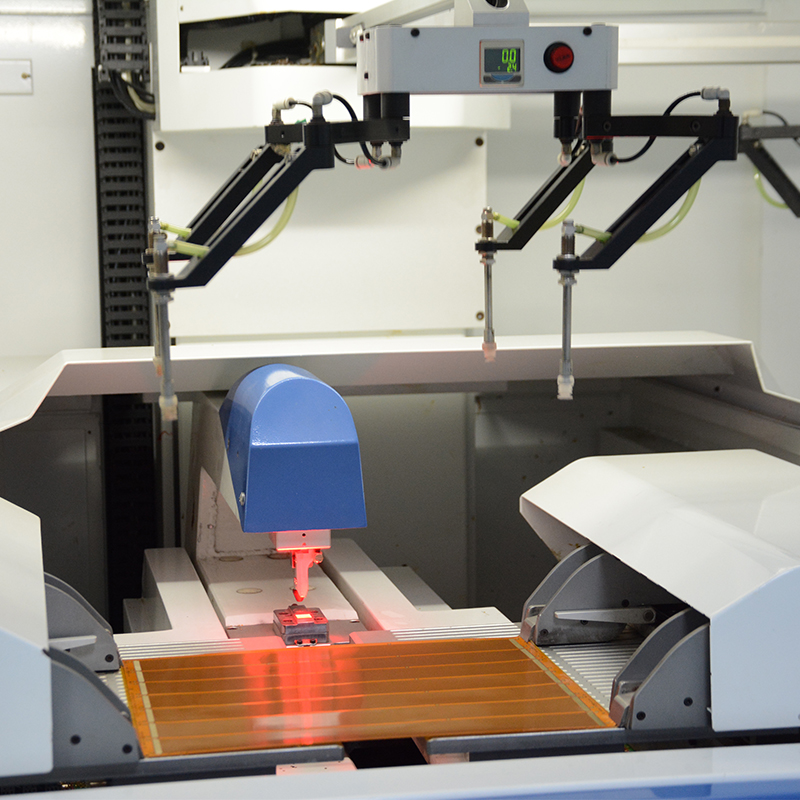

HDI PCB Prototype Process

6. Conclusion: Embrace the future of HDI PCB prototype

In summary, HDI PCB prototypes are the cornerstone of modern electronic manufacturing advancements. The advantages they offer in terms of enhanced performance, reliability, and reduced cost and production time make them indispensable in the industry. Choosing the right manufacturer is crucial to ensuring the successful implementation of HDI PCB prototyping, and as the technology continues to evolve, further developments in HDI technology will undoubtedly continue to revolutionize PCB prototyping manufacturing.

Post time: Jan-31-2024

Back