Single Layer flexible pcb – 1 layer fpc leverages cutting-edge technology to enhance vehicle performance

When it comes to vehicle performance, every detail matters. From the engine to the brakes to the electrical system, each component plays a vital role in ensuring your vehicle operates optimally. Flexible printed circuit boards (FPCs), especially single-layer FPCs, are an often overlooked but extremely important component. In this blog, we will explore the role of single-layer FPC (Flexible PCB) in enhancing vehicle performance and how it is revolutionizing the automotive industry.

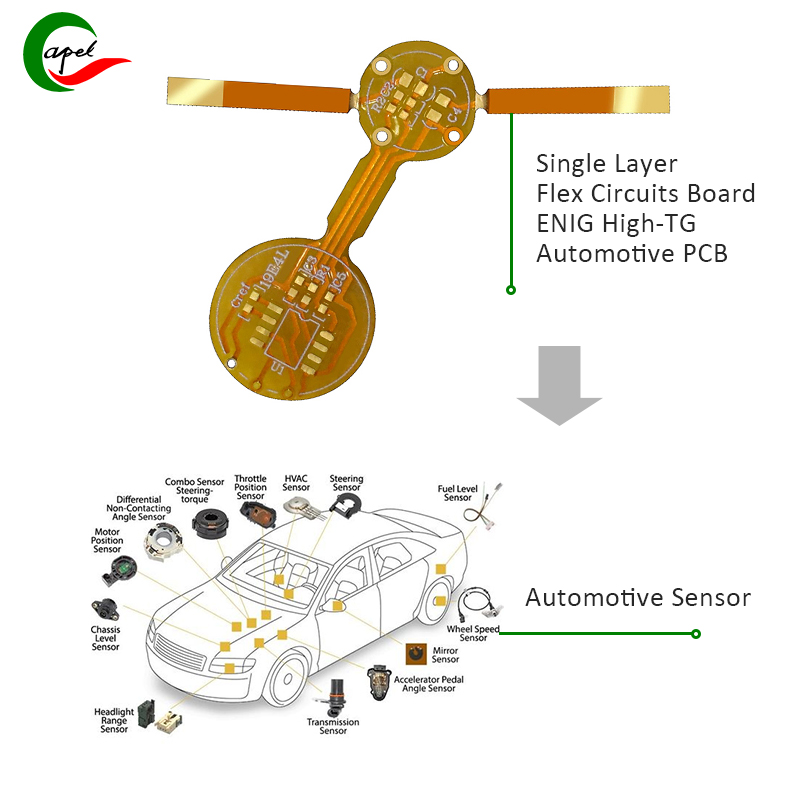

Product description: Single layer FPC-Flexible PCB

Single Layer FPC – Flexible PCB is a single layer printed circuit board designed to provide high performance and reliability for automotive applications. The line width and line spacing of this FPC are 0.2/0.25mm, the plate thickness is 0.13mm, and the film thickness is 50um. It is specially designed to meet the strict requirements of the automotive industry. It also has 1oz hole copper thickness, ENIG 2-3uin surface treatment, and can withstand high temperatures up to 135 degrees for 200 hours without carbonization. In addition, it has been tested for 48 hours of salt spray resistance, making it corrosion-resistant and ideal for automotive sensor applications.

Features and Benefits for Automotive Applications

Single Layer FPC – Flexible PCB has several key properties that make it ideal for automotive applications. Its corrosion- and temperature-resistant properties ensure it can withstand the harsh conditions of the automotive environment, including extreme temperatures and exposure to corrosive elements. This makes it a reliable and durable component of automotive electronics, helping to improve performance and longevity.

Single-layer FPC technology analysis

A careful look at the product description shows that single-layer FPC-flexible PCB is the product of advanced technological capabilities. Its precise line widths and spacings, as well as sheet and film thicknesses, demonstrate the intricate engineering that went into its design. The surface treatment of ENIG 2-3uin further enhances its performance and durability, making it an excellent choice for automotive applications. In addition, its ability to withstand high temperatures and corrosion demonstrates the product’s technical prowess and innovative design.

Company expertise and innovation in automotive electronics

Capel is a manufacturer of single-layer FPC (Flexible PCB) with 16 years of experience in automotive flexible PCB manufacturing. This extensive experience highlights the company’s expertise and dedication to producing high-quality, cutting-edge products that meet the specific needs of the automotive industry. With a strong focus on innovation and quality, Capel is at the forefront of technological advancements in automotive electronics.

Single Layer FPC – Flexible PCB Process

In conclusion

Single Layer FPC – Flexible PCB is a game changer for improving vehicle performance. Its advanced technical specifications, corrosion and temperature resistance, and manufacturer’s expertise make it a valuable component for the automotive industry. As automobiles continue to evolve with new technologies and innovations, single-layer FPC – flexible PCB is expected to play a central role in driving these advancements. With Capel’s commitment to excellence and innovation, the future of automotive electronics looks brighter than ever.

Post time: Feb-23-2024

Back