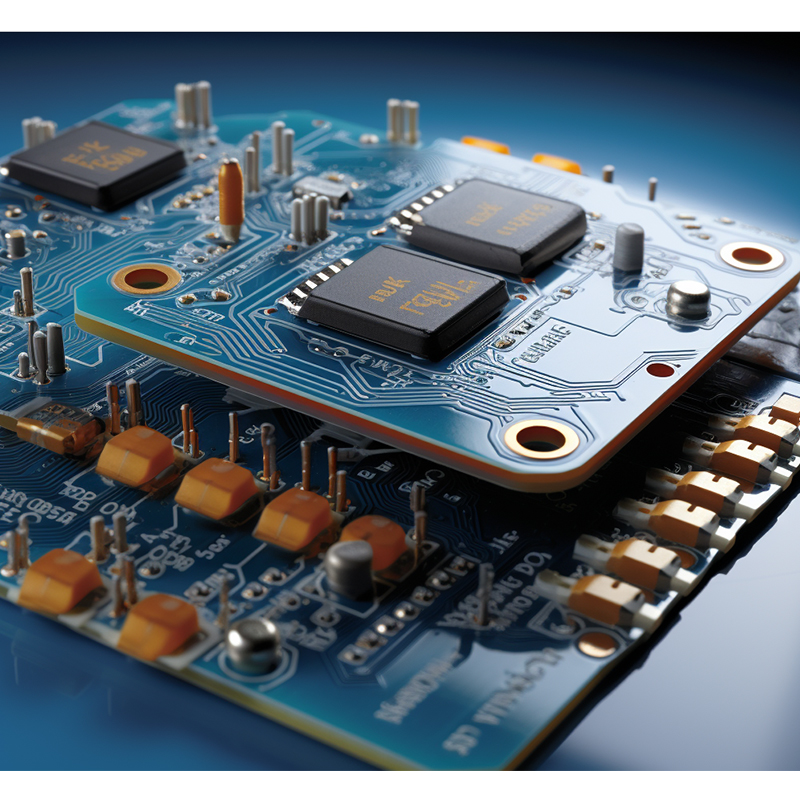

Overheating and thermal stress can be significant challenges in rigid-flex circuit board operation. As these boards become more compact and complex, managing heat dissipation and ensuring proper operation becomes critical. In this blog post, we’ll explore various ways to protect rigid-flex circuit boards from overheating and thermal stress during operation, keeping them reliable and running at their best.

1. Adequate design and layout considerations:

Design and layout play a vital role in protecting rigid-flex circuit boards from overheating and thermal stress. Proper consideration of factors such as component placement, heat sinks, and thermal vias can significantly improve a board’s thermal dissipation capabilities. Adequate spacing between components, especially heat-generating components, helps avoid localized heating. Implementing a thoughtful layout that promotes efficient airflow can also help dissipate heat.

2. Effective thermal management solutions:

Utilizing thermal management solutions can improve the reliability and longevity of rigid-flex circuit boards. These solutions include combining heat sinks, thermal pads and thermally conductive heat transfer materials. Radiators are often used to draw heat away from specific components and distribute it efficiently over a wider area. Thermal pads can improve heat transfer between components and heat sinks by filling gaps and eliminating air pockets. In addition, the use of thermally conductive materials such as thermal paste or thermal glue can ensure effective heat dissipation.

3. Optimize material selection:

Proper material selection is another important aspect in protecting rigid-flex circuit boards from overheating and thermal stress. Choosing materials with high thermal conductivity can help dissipate heat efficiently. For example, choosing a circuit board base material with a higher thermal conductivity, such as aluminum-based or copper-based materials, can provide a better heat transfer path. Additionally, considering materials with lower coefficients of thermal expansion (CTE) can help minimize the risk of failure caused by thermal stress.

4. Well-designed ventilation and airflow system:

Implementing a well-designed ventilation system can help prevent hot air pockets from forming within the circuit board enclosure. By ensuring consistent airflow across the board, hot air is expelled, thereby promoting the introduction of cold air. This can be accomplished by strategically placing vents, fans, and other cooling mechanisms to maintain a steady flow of air. Adequate ventilation not only prevents overheating, but also improves the overall performance and reliability of rigid-flex circuit boards.

5. Thorough testing and simulation:

Thorough testing and simulation is critical when it comes to protecting rigid-flex circuit boards from overheating and thermal stress. Prior to deployment, circuit boards must be rigorously tested under a variety of operating conditions. Thermal imaging cameras can be used to identify hot spots and areas of high heat concentration. In addition, computer-aided simulation tools can help model and predict the thermal behavior of circuit boards to optimize prior to production.

6. Continuous monitoring and maintenance:

Once a rigid-flex circuit board is operational, it is important to implement ongoing monitoring and maintenance practices. Regular inspections for signs of overheating or thermal stress, such as unusual hot spots or component failures, can help catch potential problems before they escalate. Implementing a proactive maintenance program that includes cleaning, inspection, and component replacement when necessary can significantly increase circuit board life and reliability.

In summary, protecting rigid-flex circuit boards from overheating and thermal stress is a multifaceted task that requires careful consideration during the design phase, material selection, and implementation of effective thermal management solutions. By incorporating strategies such as optimizing design layout, utilizing thermal management solutions, selecting appropriate materials, ensuring proper airflow, conducting thorough testing, and implementing consistent monitoring and maintenance practices, you can successfully reduce the risk associated with overheating and thermal stress in rigid structures. Stress-related risks. -Flexible circuit boards to ensure their optimal performance and longevity.

Post time: Sep-20-2023

Back