Can rigid-flex PCBs really be used in robotics and automation applications? Let’s delve deeper into the issue and explore the possibilities.

In today’s fast-paced world, technological advancements continue to reshape industries and shape the way we live. Robotics and automation are one of the areas where innovative technologies are making significant strides. These areas are experiencing unprecedented growth and are expected to transform industries as diverse as manufacturing, healthcare, and even transportation. In this wave of innovation, printed circuit boards (PCBs) are a key component that plays an important role in the development of robotics and automation. In particular, rigid-flex PCBs are attracting attention for their potential to revolutionize these industries.

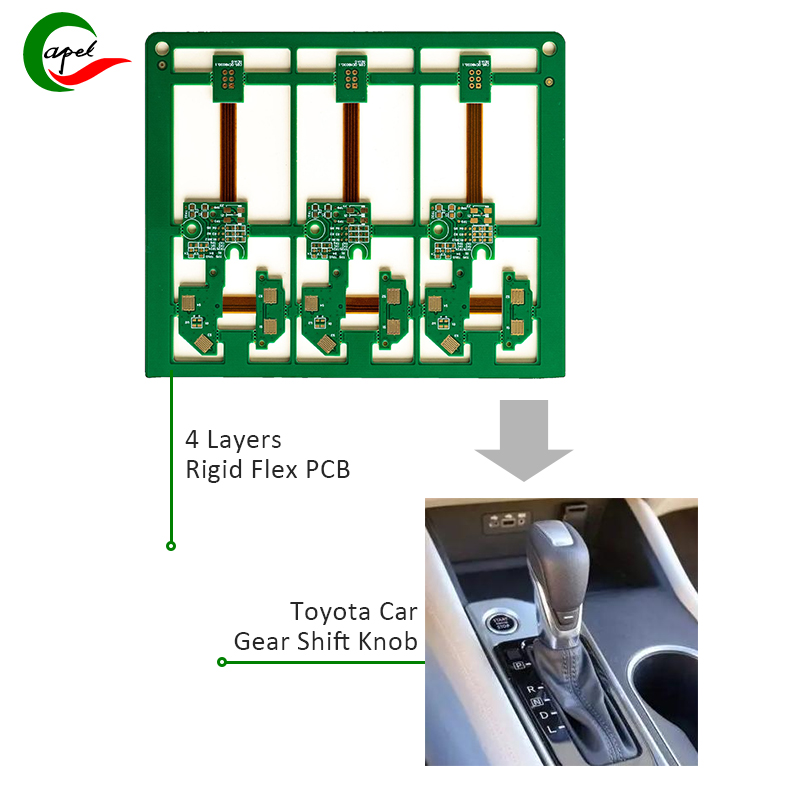

First, we need to understand the unique features of rigid-flex PCBs and how they differ from traditional PCBs. A rigid-flex PCB is a hybrid board that combines rigid and flexible PCB components. This combination gives the board a combination of ruggedness and flexibility, ensuring it can withstand the rigors of a variety of applications while also being able to fit into tight spaces. This design innovation provides unparalleled freedom in designing and implementing complex circuits, making rigid-flex PCBs ideal for robotics and automation.

One of the main advantages of using rigid-flex boards in robotics and automation is their ability to improve overall system performance. The flexibility of these boards allows seamless integration into the mechanical components of a robot or automation system, increasing reliability and durability. Additionally, due to the flexibility of rigid-flex PCBs, the number of connectors and interconnections is reduced, reducing the risk of signal interference and increasing overall system efficiency.

Additionally, the form factor of rigid-flex boards is another factor that makes them suitable for robotics and automation applications. Traditional rigid PCBs are limited by their fixed form and often require additional connectors and wiring to accommodate different designs. In contrast, rigid-flex PCBs alleviate this concern by being able to fit into the available space within a robotic or automated system. With this design flexibility, engineers can optimize layout and reduce the overall size of the PCB, enabling the development of smaller, more compact robotic applications.

Rigid-flex PCB integration can also save costs in the long run. Fewer connectors and interconnects mean lower manufacturing and assembly costs as well as lower maintenance and repair expenses. This cost-effectiveness combined with the durability and reliability of rigid-flex boards makes it an attractive option for robotics and automation applications.

In addition, rigid-flex boards provide enhanced signal transmission capabilities, which is critical for robotics and automation systems that rely heavily on precise data transmission. The flexibility of these boards allows for efficient signal routing, minimizing signal loss, distortion and crosstalk. This ensures accurate, real-time data transfer between different components of the system, thereby improving the overall performance and responsiveness of robotics and automation systems.

It’s worth mentioning that while rigid-flex PCBs show great potential for robotics and automation applications, their successful integration does require careful planning and consideration. Engineers and designers must evaluate factors such as thermal management, mechanical stress and environmental conditions that are specific to each application. If these factors are not addressed, the performance, reliability, and durability of the rigid-flex board and overall system may suffer.

In summary, rigid-flexible PCBs are expected to revolutionize the robotics and automation industries. Their unique combination of flexibility, durability and efficiency make them ideal for designing and developing advanced robotic applications. The ability to optimize layout, reduce size, enhance signal transmission and cut costs makes rigid-flex boards a game-changer in robotics and automation. As technology continues to evolve, we can expect to witness more exciting and innovative rigid-flex PCB applications, paving the way for a future where robotics and automation systems play an increasingly important role in our lives.

Post time: Sep-20-2023

Back