Introduction :

Satellite communications systems play a vital role in modern connectivity, enabling communications, navigation, and remote sensing on a global scale. As the need for efficient, reliable satellite communications continues to grow, individuals and organizations often wonder if they can prototype their own printed circuit boards (PCBs) for such systems. In this blog post, we will explore the process of PCB prototyping for satellite communications systems, discussing its feasibility, challenges, and key considerations to keep in mind. So, let’s dig into it!

Understanding satellite communication systems :

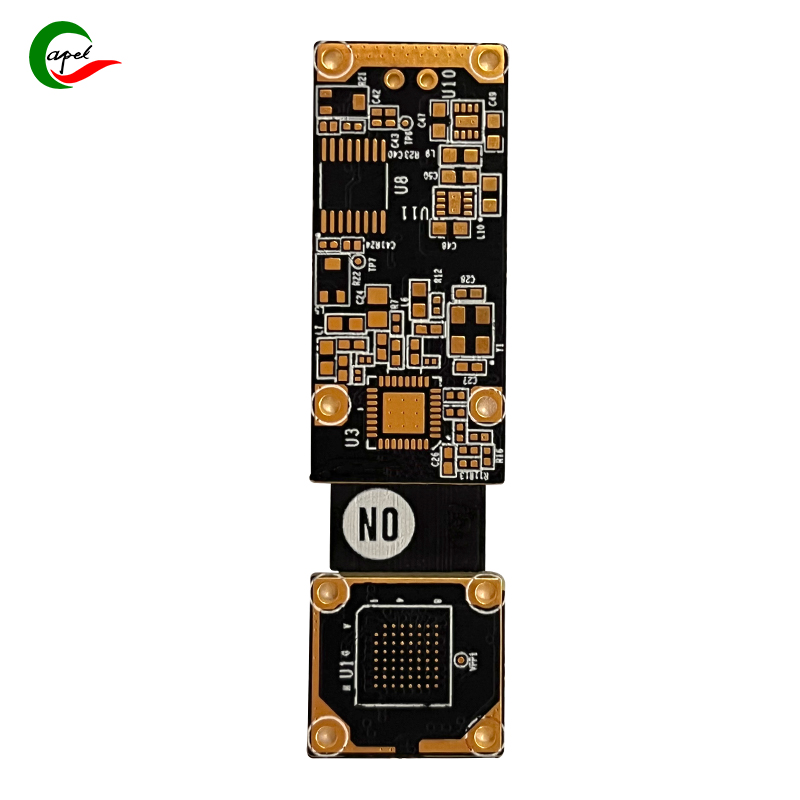

Before delving into PCB prototyping, it is important to understand the basics of satellite communications systems. These systems involve the transmission of data, voice, or video signals between satellites and ground stations or user terminals. They rely on complex hardware including antennas, transmitters, receivers, and signal processing components, all interconnected by high-performance PCBs.

Feasibility of PCB prototyping design of satellite communication system :

While it is technically possible to prototype a PCB for a satellite communications system, it is important to understand that the process presents many challenges. Satellite communications systems operate in frequency ranges up to several gigahertz, requiring highly precise PCB designs. These designs must minimize signal loss, maximize signal integrity, and promote efficient power distribution among different components.

Satellite communication system PCB prototype production process :

1. Define your requirements: Start by precisely defining the requirements for your satellite communications system. Consider factors such as signal frequency, data rate, power requirements, environmental constraints, and available space.

2. Design phase: Create the PCB schematic, ensuring all necessary components are included. Use specialized PCB design software to develop a layout that optimizes signal flow and minimizes interference.

3. Component selection: Carefully select components that meet the strict requirements of the satellite communication system. Consider factors such as appropriate frequency range, power handling capabilities, and environmental adaptability.

4. PCB Manufacturing: Once the PCB design is complete, the actual circuit board can be manufactured. There are several methods to choose from, including traditional etching processes, milling techniques, or using professional PCB manufacturing services.

5. Assembly and Testing: Assemble the components onto the fabricated PCB following standard soldering techniques. After assembly, test your prototype thoroughly to ensure it meets the expected requirements. Testing may include power distribution, signal integrity, and environmental resiliency assessments.

Challenges faced in PCB prototyping design of satellite communication systems :

PCB design and prototyping of satellite communication systems face several challenges due to the technical complexity and demanding requirements of the system. Some common challenges include:

1. High-frequency design: Operating at high frequencies requires specialized design techniques to manage signal loss and maintain signal integrity throughout the PCB.

2. Impedance matching: Ensuring accurate impedance matching is critical to minimizing signal reflections and maximizing signal transmission efficiency.

3. Noise and interference: Satellite communications systems must be able to withstand the harsh environmental conditions of space and the Earth’s surface. Therefore, incorporating adequate noise suppression techniques and shielding strategies is crucial.

4. Power Distribution: Efficient power distribution between the various components of a satellite communications system is critical. Proper PCB design techniques such as power planes and dedicated power traces must be used.

Things to note before PCB prototype design of the satellite communication system :

Before you begin prototyping your satellite communications system PCB design, keep the following considerations in mind:

1. Skills and expertise: Producing advanced PCB prototypes requires a deep understanding of high-frequency design principles, signal integrity analysis, and PCB manufacturing techniques. It may be necessary to work with an experienced professional or develop the required skills through extensive study.

2. Cost and Time: PCB prototyping can be an expensive and time-consuming process. Evaluate the cost-benefit ratio and determine whether in-house prototyping or outsourcing to a professional service is the best option for your specific requirements.

Conclusion :

PCB prototyping of satellite communications systems is indeed possible but requires technical expertise, a thorough understanding of high-frequency design principles, and careful consideration of the various challenges. By following a systematic process, considering key factors, and leveraging the appropriate resources, individuals and organizations can create high-performance prototypes of their satellite communications systems. Remember, effective PCB prototyping lays the foundation for a robust and efficient satellite communications infrastructure, helping to enhance global connectivity and improve communications.

Post time: Oct-26-2023

Back