Introduce:

In this blog post, we’ll delve into the details of how the layers in a rigid-flex circuit board are bonded, exploring the various techniques used in the process.

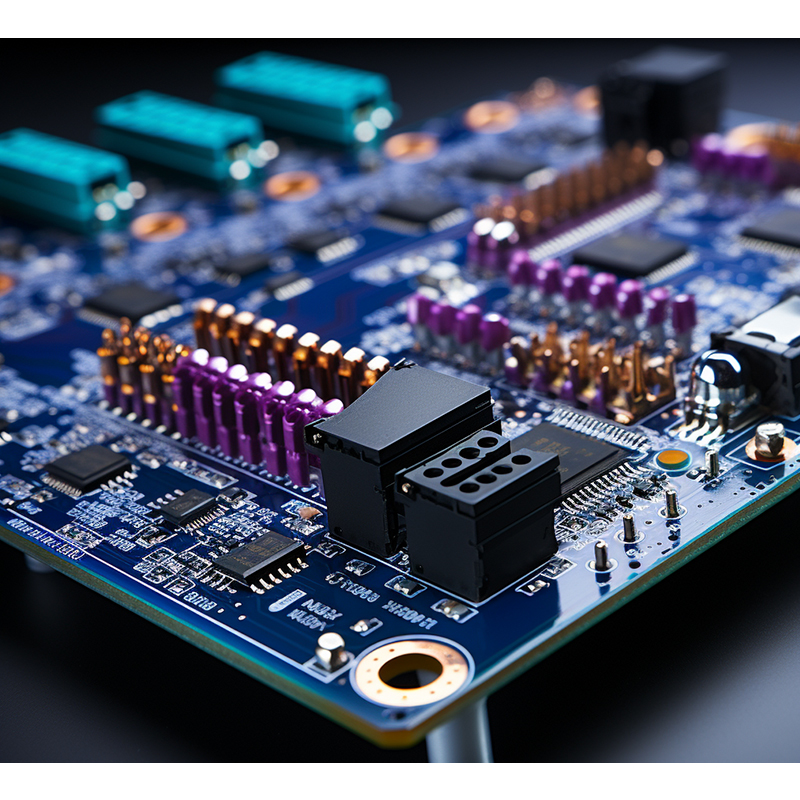

Rigid-flex circuit boards are popular in various industries including aerospace, medical, and consumer electronics. These boards are unique in that they combine flexible circuitry with rigid sections, providing durability and flexibility. One of the key aspects that ensures the functionality and reliability of rigid-flex boards is the bonding technology used to connect the different layers.

1. Bonding technology:

Adhesive bonding technology is widely used in rigid-flex circuit board manufacturing. It involves the use of a specialized adhesive that contains a heat curing agent. These adhesives are used to bond flexible layers to rigid portions of circuit boards. The adhesive not only provides structural support but also ensures electrical connections between the layers.

During the manufacturing process, adhesive is applied in a controlled manner and the layers are precisely aligned before being laminated together under heat and pressure. This ensures a strong bond between the layers, resulting in a rigid-flex circuit board with excellent mechanical and electrical properties.

2. Surface mount technology (SMT):

Another popular method of bonding rigid-flex circuit board layers is using surface mount technology (SMT). SMT involves placing surface mount components directly onto a rigid part of the circuit board and then soldering these components to the pads. This technology provides a reliable and efficient way to connect the layers while ensuring electrical connections between them.

In SMT, the rigid and flexible layers are designed with matching vias and pads to facilitate the soldering process. Apply solder paste to the pad location and place the component accurately. The circuit board is then put through a reflow soldering process, where the solder paste melts and fuses the layers together, creating a strong bond.

3. Through hole plating:

To achieve enhanced mechanical strength and electrical connectivity, rigid-flex circuit boards often use through-hole plating. The technique involves drilling holes into the layers and applying conductive material inside those holes. A conductive material (usually copper) is electroplated onto the walls of the hole, ensuring a strong bond and electrical connection between the layers.

Through-hole plating provides additional support to rigid-flex boards and minimizes the risk of delamination or failure in high-stress environments. For best results, drill holes need to be carefully positioned to align with vias and pads on different layers to achieve a secure connection.

In Conclusion:

The adhesive technology used in rigid-flex circuit boards plays a fundamental role in ensuring their structural integrity and electrical performance. Adhesion, surface mount technology and through-hole plating are widely used methods to seamlessly connect different layers. Each technology has its advantages and is chosen based on the specific requirements of the PCB design and application.

By understanding the bonding techniques used in rigid-flex circuit boards, manufacturers and designers can create robust and reliable electronic assemblies. These advanced circuit boards meet the growing demands of modern technology, allowing the implementation of flexible and durable electronics in various industries.

Post time: Sep-18-2023

Back