Introduce

when it comes to maintenance and cleaning, many PCB users are unsure whether rigid-flex boards can be washed or cleaned without causing any damage. In this blog post, we’ll dive into this topic to provide you with valuable insights and guidance. So let’s get started!

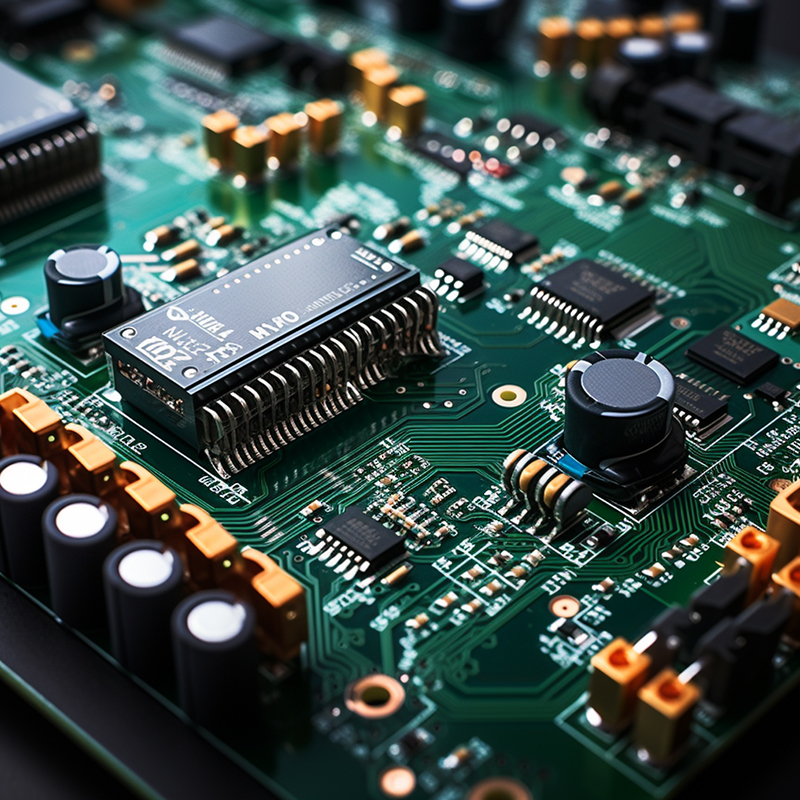

Printed circuit boards (PCBs) are an integral part of modern electronic equipment. They provide electrical connections and support for various components. As technology advances, more complex and multifunctional PCB designs have emerged, including rigid-flex PCBs. These boards combine rigid and flexible components to provide enhanced functionality and usability.

Learn about rigid-flex boards

Before we discuss the cleaning process of rigid-flex boards, it is necessary to understand their structure and composition. Rigid-flex PCBs are made from multiple layers of rigid and flexible materials, such as FR-4 and polyimide. These layers are interconnected using plated through holes and flex connectors. They offer advantages such as space saving, increased durability and improved reliability.

Why clean rigid-flex boards?

Like any other PCB, rigid-flex boards can accumulate dust, dirt, and other contaminants during the manufacturing process or during use. These contaminants can affect PCB performance and longevity. Therefore, regular cleaning is necessary to maintain optimal functionality and prevent potential problems.

How to clean rigid-flex boards

When cleaning rigid-flex boards, it’s critical to use proper techniques and precautions to avoid damaging the board. Here are some approved methods for cleaning these boards:

1. Isopropyl alcohol (IPA) method: This method involves gently wiping the PCB surface with a lint-free cloth or cotton swab dipped in IPA solution. IPA is a commonly used solvent that effectively removes contaminants without leaving any residue. However, it is important to use a minimum amount of IPA and avoid excess moisture as it may penetrate the flex areas and cause damage.

2. Ultrasonic cleaning: Ultrasonic cleaning is a commonly used method in PCB cleaning. It involves immersing the PCB in a cleaning solution while ultrasonically treating it. The vibrations generated by the waves remove contaminants and effectively clean the circuit board. However, extreme caution should be used when using this method as overheating or overpressure can damage the flexible parts of the PCB.

3. Vapor phase cleaning: Vapor phase cleaning is another effective method for cleaning rigid-flex boards. The process involves exposing the PCB to vaporized cleaner, which condenses on the board surface and dissolves contaminants. This technology ensures deep cleaning without promoting any moisture intrusion. However, it requires specialized equipment and expertise, making it less accessible to the average user.

Precautions to be followed

While cleaning rigid-flex boards is crucial, it is equally important to follow certain precautions to avoid any damage. Here are some tips to remember:

1. Avoid using abrasive materials: Do not use abrasive materials such as brushes or scrubbing pads as they can scratch or damage the delicate surface of the PCB.

2. Do not immerse PCB in water: Do not immerse PCB in any liquid solution unless using an approved method such as ultrasonic cleaning. Excess moisture can seep into the flex areas and cause damage.

3. Handle with care: Always handle PCBs with clean hands and avoid bending or bending the board beyond its limits as this may cause stress cracks or breakage

In Conclusion:

In summary, yes, you can wash or clean rigid-flex boards, but you must follow the correct methods and precautions to prevent any damage. Regular cleaning helps maintain the performance and longevity of these advanced PCBs. Whether you choose the IPA method, ultrasonic cleaning or vapor cleaning, be careful and avoid excessive moisture or pressure.

If you are not sure how to clean a rigid-flex board or handle any other maintenance-related issues, it is recommended to seek professional help or consult the PCB manufacturer. Keeping your PCB clean and well-maintained will ensure optimal performance and reliability of your electronic devices.

Post time: Sep-18-2023

Back