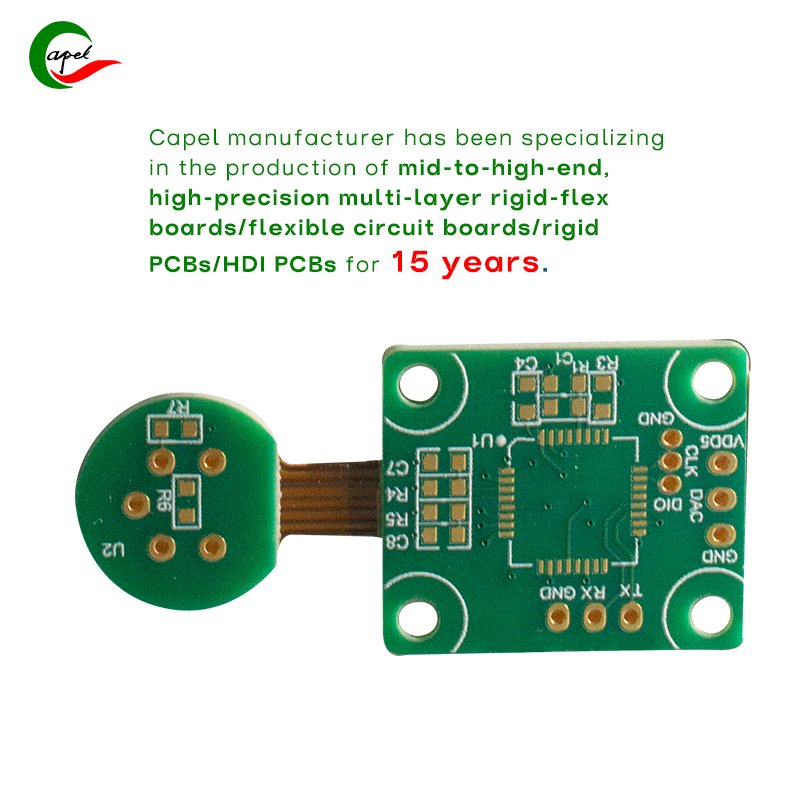

In this blog post, we will discuss the key factors to consider when selecting connectors for rigid-flex PCB designs.

Are you working on a rigid-flex PCB design and wondering how to choose the right connector? Well, you’ve come to the right place! Whether you are an experienced engineer or a beginner, understanding these guidelines will help you make the right decisions for your designs. So, let’s get started!

1. Electrical performance:

One of the most important factors to consider when selecting a connector for a rigid-flex PCB design is its electrical performance. You need to make sure the connector can handle the required voltage, current, and signal integrity. Look for connectors with low insertion loss and good impedance matching. Additionally, check the rated current capacity of the connector to ensure it can meet the power requirements of your design.

2. Mechanical reliability:

Because rigid-flex PCB designs experience repeated bending and flexing, mechanical reliability is critical for connectors. Choose connectors specifically designed for use with flexible circuits. These connectors should have high cycle life and excellent bending fatigue resistance. Also consider the connector’s durability with respect to temperature cycling, vibration, and shock.

3. Dimensions and appearance:

Connector size and form factors play an important role in designing compact and efficient rigid-flex PCBs. Depending on your application, choose a connector that fits the available space on the board. Micro connectors are often favored for their space-saving advantages. Additionally, the connector should be properly aligned with the circuit and ensure a secure connection without any misalignment issues.

4. Environmental considerations:

When selecting connectors for a rigid-flex PCB design, the environmental conditions in which the PCB will be used must be analyzed. Consider factors such as temperature, humidity, and exposure to chemicals or moisture. Choose connectors with the appropriate level of protection and corrosion resistance to handle environmental challenges. This will ensure long-term performance and reliability of the PCB design.

5. Signal integrity:

Maintaining signal integrity is critical to any PCB design, including rigid-flex designs. Connectors should have excellent impedance control and signal shielding capabilities to minimize noise and electromagnetic interference. Look for connectors with low crosstalk and impedance mismatch to ensure optimal signal quality throughout the flex portion of the PCB.

6. Easy to assemble:

Another aspect to consider is the ease of assembling the connector onto a rigid-flex PCB. Choose connectors that are easy to install, remove, and rework (if necessary). Connectors with features like surface mount options or press-fit technology can simplify the assembly process and provide a reliable connection.

7. Supplier Support and Certification:

Before finalizing your connector selection, it’s worth considering the level of vendor support available. Check to see if the connector manufacturer provides technical support, documentation, and design guides to facilitate your PCB design process. It is also recommended to choose connectors that are certified by industry standards organizations to ensure their quality and compliance.

In Summary:

Selecting the right connector for a rigid-flex PCB design requires careful consideration of electrical performance, mechanical reliability, size, environmental factors, signal integrity, ease of assembly, and supplier support. By keeping these factors in mind and doing thorough research, you can make informed decisions that lead to a successful and robust rigid-flex PCB design.

Keep in mind that the connector you choose can significantly impact the overall performance and reliability of your design. So take the time to analyze your requirements, consult with experts as needed, and select a connector that meets your specific design needs. Happy designing!

Post time: Sep-18-2023

Back